System and method for testing thin film thermoelectricity material Seebeck coefficient

A testing system and Seebeck coefficient technology, applied in the direction of material analysis, material analysis, material resistance, etc. by electromagnetic means, can solve the problems that there are no applicable thin-film thermoelectric material instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

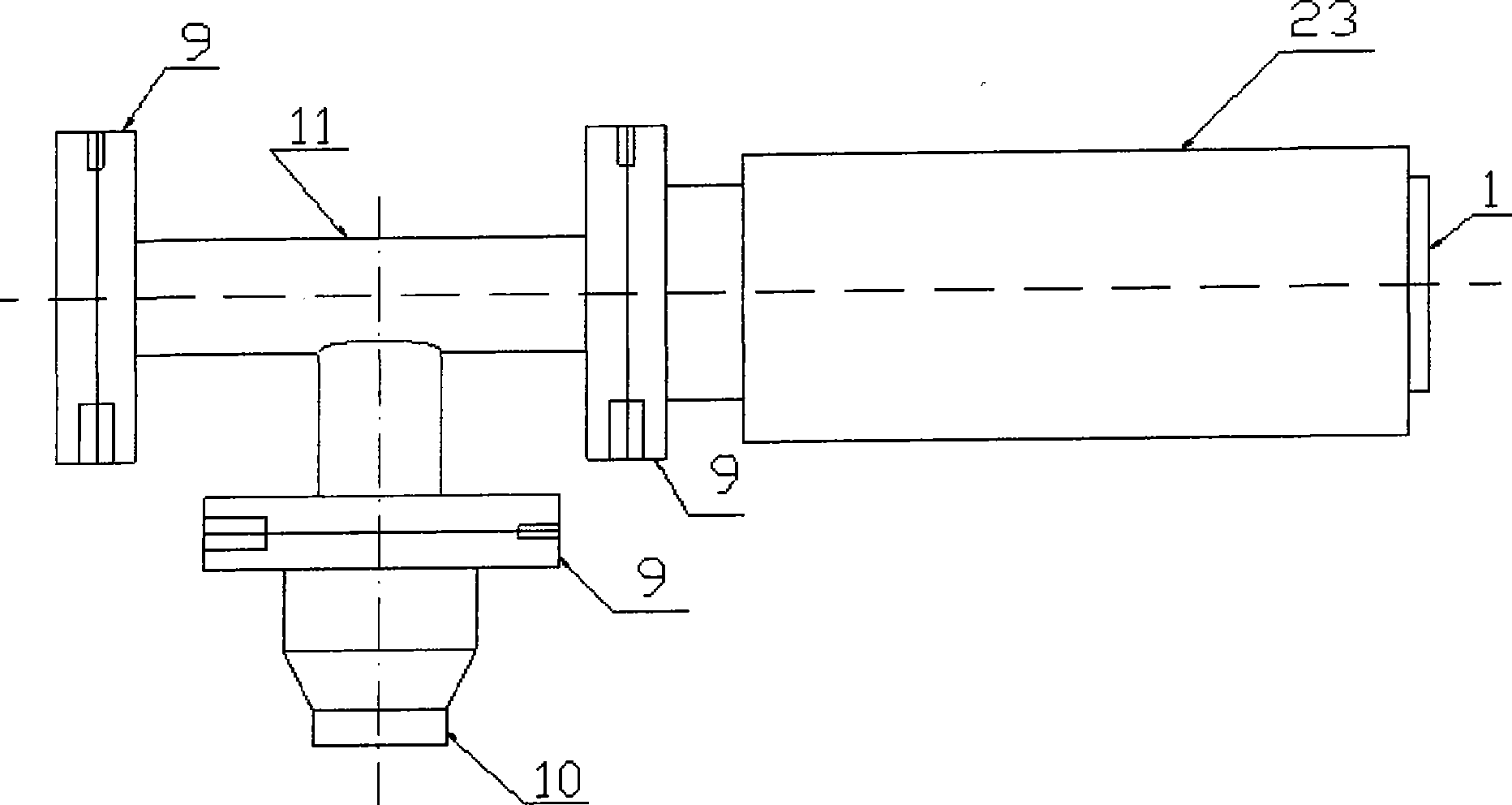

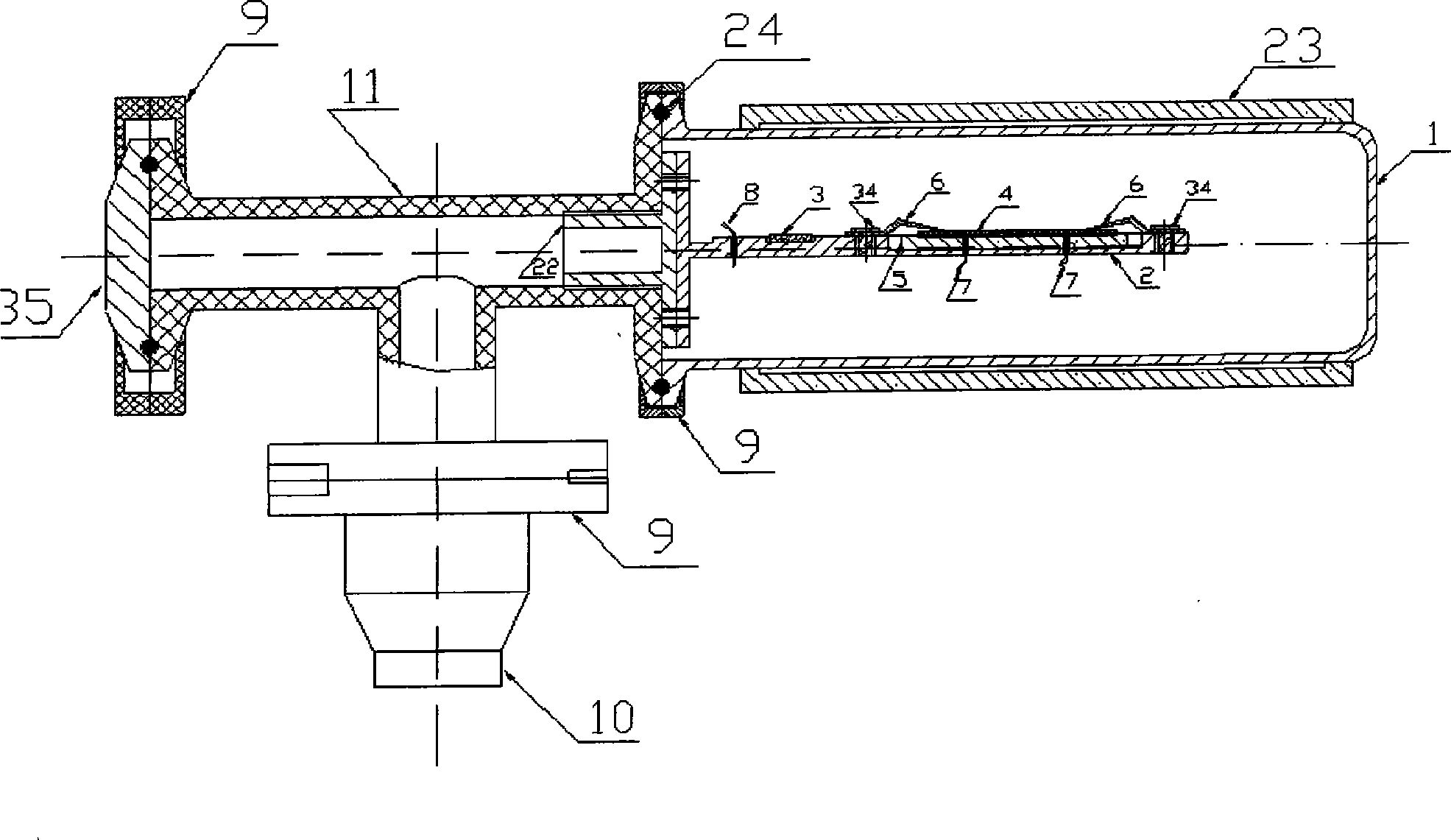

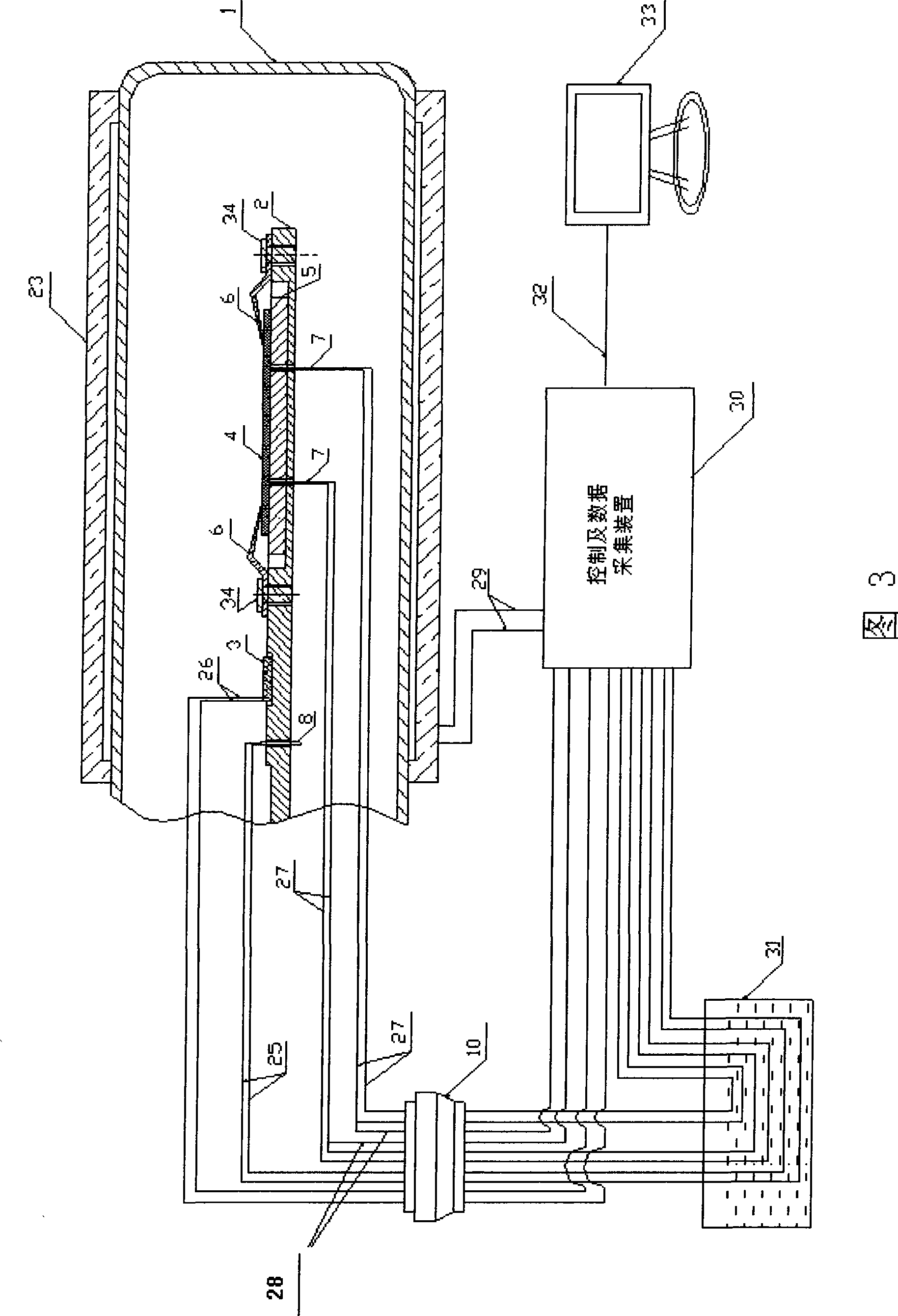

[0026] figure 1 and figure 2It is a schematic diagram of the appearance structure of the test device and a section view of part of the internal structure. The test device consists of a sample support frame cover 1, a sample support frame 2, a heating block 3, a sample to be tested 4, an insulating sheet 5, a sample fixing card 6, a sample fixing card fixing screw 34, a sample temperature measuring thermocouple 7. Sample chamber temperature measuring thermocouple 8, sealing clamp 9, outer lead interface 10, outer lead tee 11, sample support frame connection port 22, sample chamber heater 23, sealing ring 24, tee sealing cover 35 and so on. The inside of the sample support frame cover 1 forms a sample chamber for placing the sample to be tested. The sample 4 to be tested is placed on the insulating sheet 5 on the sample support frame 2, and is in close contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com