Cold storage instant auto-defrosting control device

A cold storage and control circuit technology, which is applied in the field of real-time automatic frost control devices for cold storage, can solve problems such as easy frost accumulation, stop cooling, and difficulty in ensuring instant defrosting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

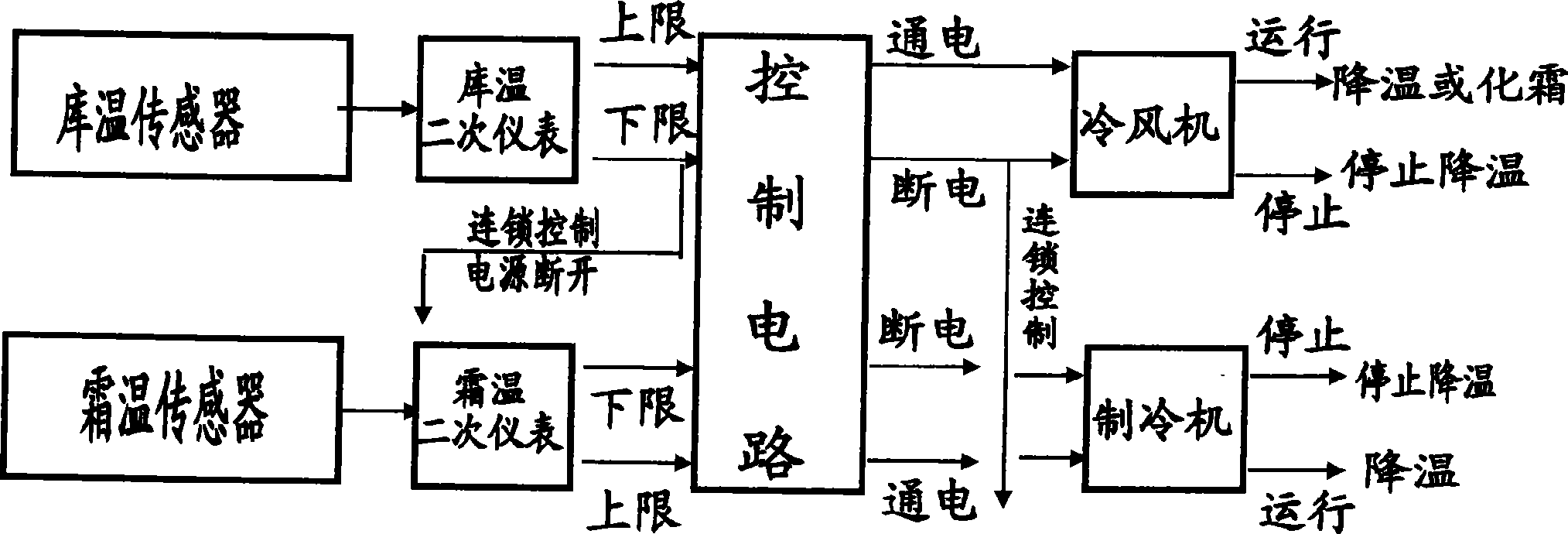

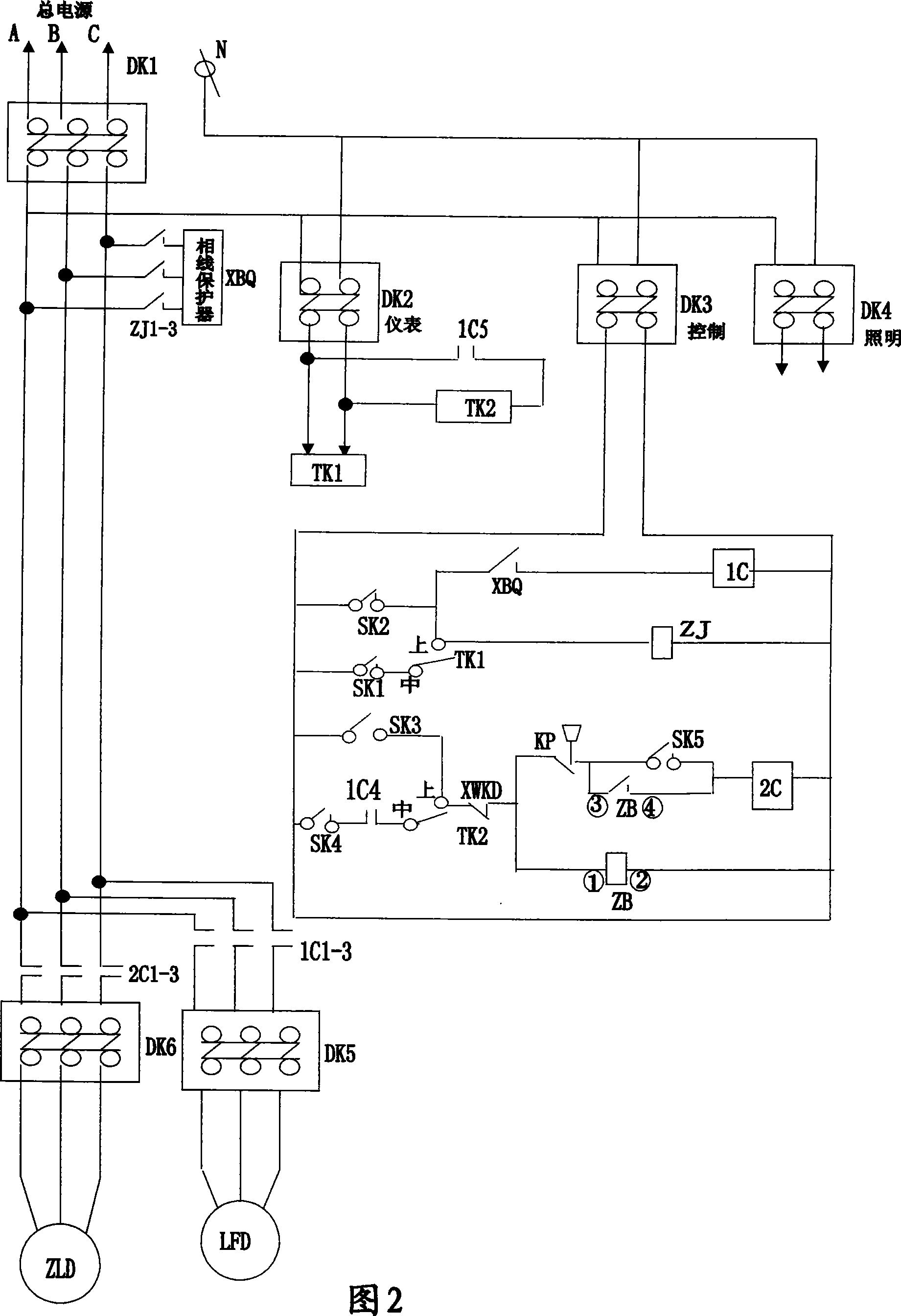

[0012] Such as figure 1 As shown, the automatic control device includes a storage temperature sensor, a storage temperature secondary instrument, a control circuit and a cooling fan connected in sequence, and also includes a frost temperature sensor, a frost temperature secondary instrument, a control circuit and a refrigerator connected in sequence. When the temperature sensed by the storage temperature sensor reaches the upper limit temperature set by its secondary instrument, the corresponding control circuit will start the cooling fan in the storage, and the frost temperature sensor on the evaporator of the cooling fan and its secondary instrument will start to work. When there is frost on the surface of the evaporator, the frost temperature secondary instrument stops the refrigerator through the control circuit, and the air cooler evaporator starts to defrost; If it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com