Pressure detecting sensor

A technology for detecting sensors and pressure, applied in the field of sensors, can solve the problems of high temperature compensation and circuit requirements, complex structure, difficult processing, etc., to achieve the effect of improving reliability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

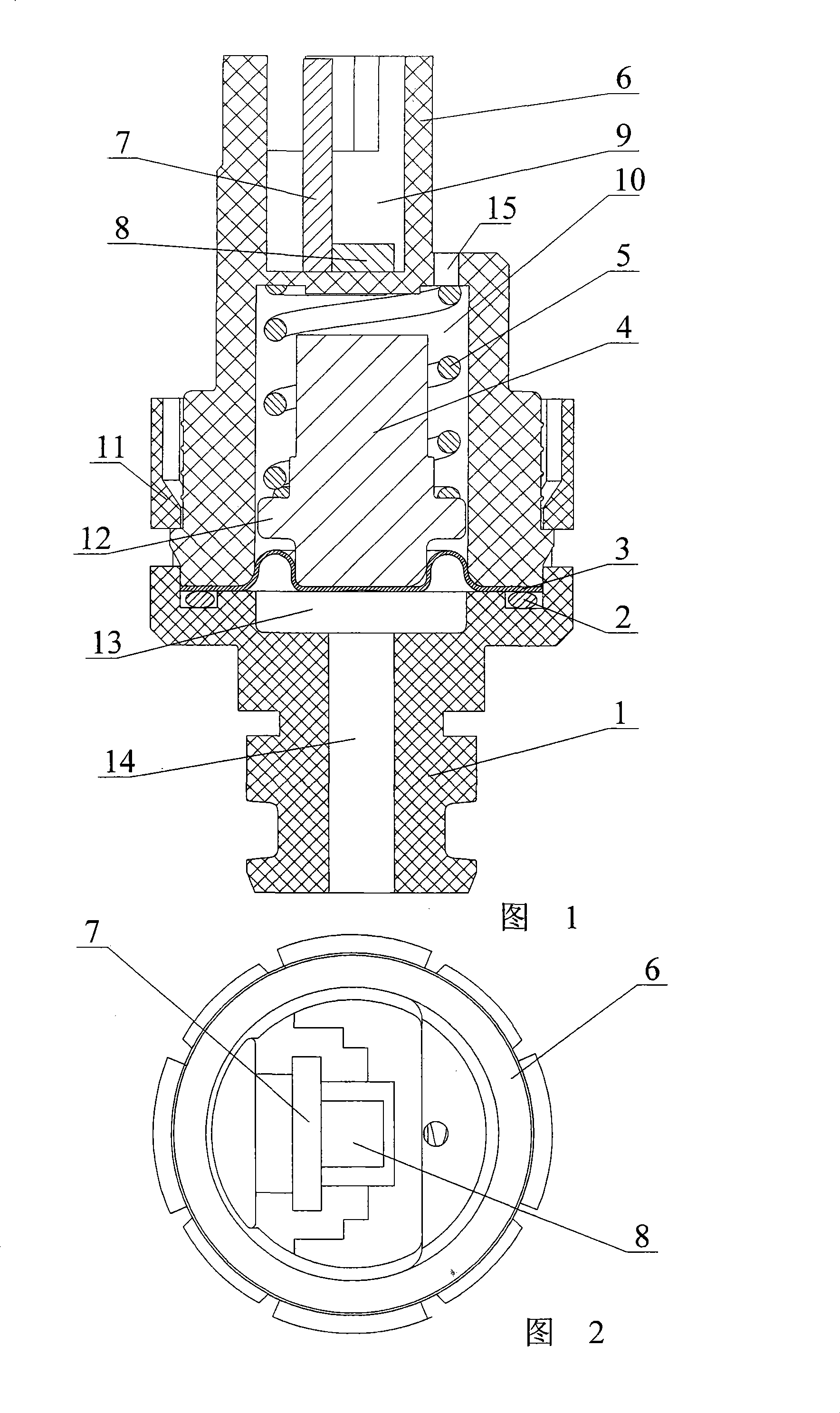

[0011] As shown in the figure: there is a connecting sleeve 6 on the top of the base 1, and a non-magnetic elastic diaphragm 3 is arranged at the junction of the base 1 and the connecting sleeve 6; the upper part of the connecting sleeve 6 is the output cavity 9, and the lower part is Acquisition chamber 10; a linear programmable Hall device 8 is set in the output chamber 9; a magnetic device that can move up and down in the collection chamber 10 is set in the collection chamber 10 under the drive of the non-magnetic elastic diaphragm 3 Steel 4; the lower end of the magnetic steel 4 is in contact with the nonmagnetic elastic diaphragm 3, and the upper part of the magnetic steel 4 is provided with an elastic body for making the lower end surface of the magnetic steel 4 contact the nonmagnetic elastic diaphragm 3. When working, the gas enters the bottom of the non-magnetic elastic diaphragm 3 from the base 1, and presses the non-magnetic elastic diaphragm 3. The non-magnetic elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com