Automatic flame cutting machine synchronization mechanism of slab caster

A technology of flame cutting machine and slab continuous casting machine, which is applied in the field of mechanical devices, can solve the problems of erratic position of the indenter, affect the reputation, weaken the pre-compression effect of the synchronization mechanism, etc., and achieve the effect of convenient debugging and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

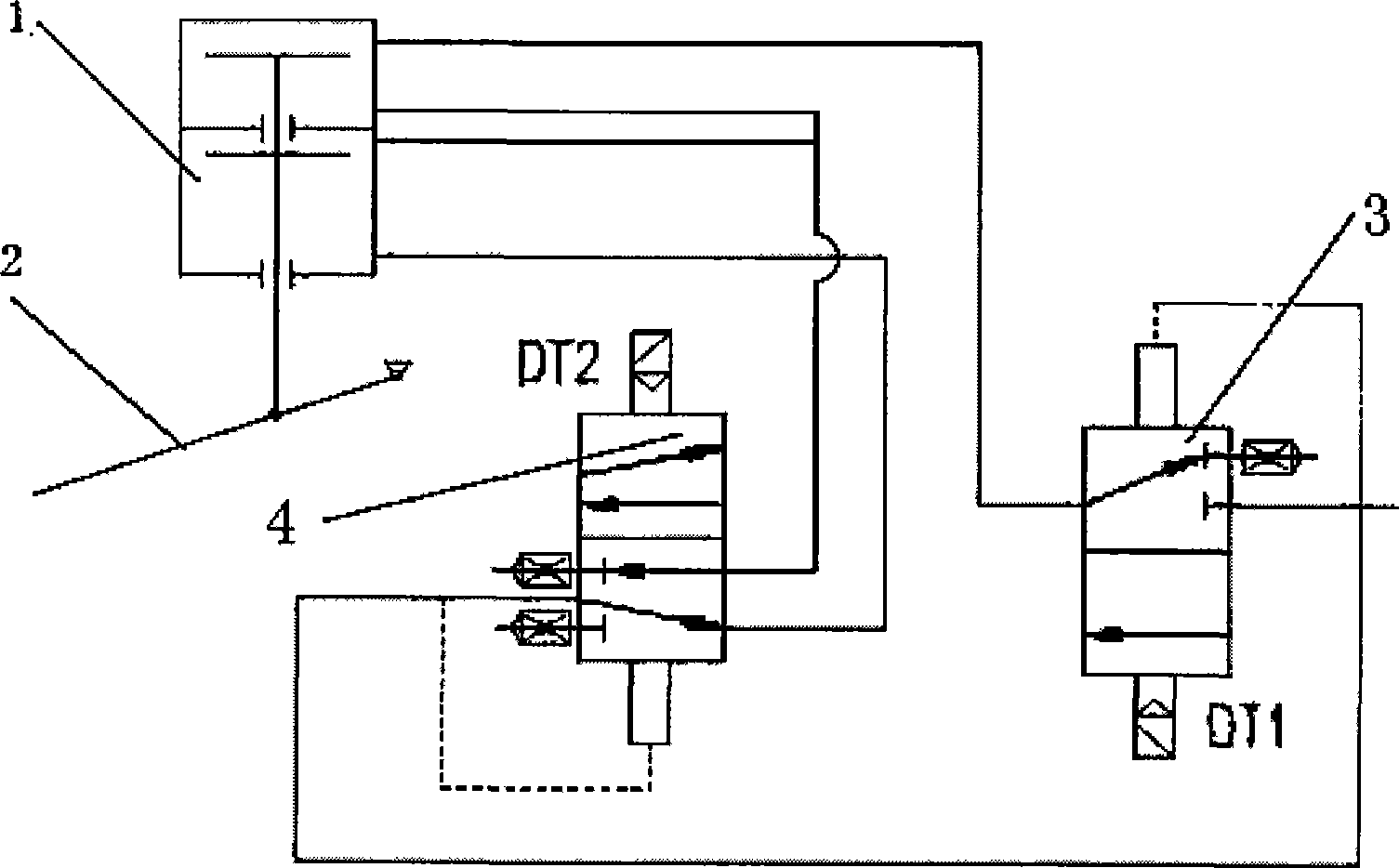

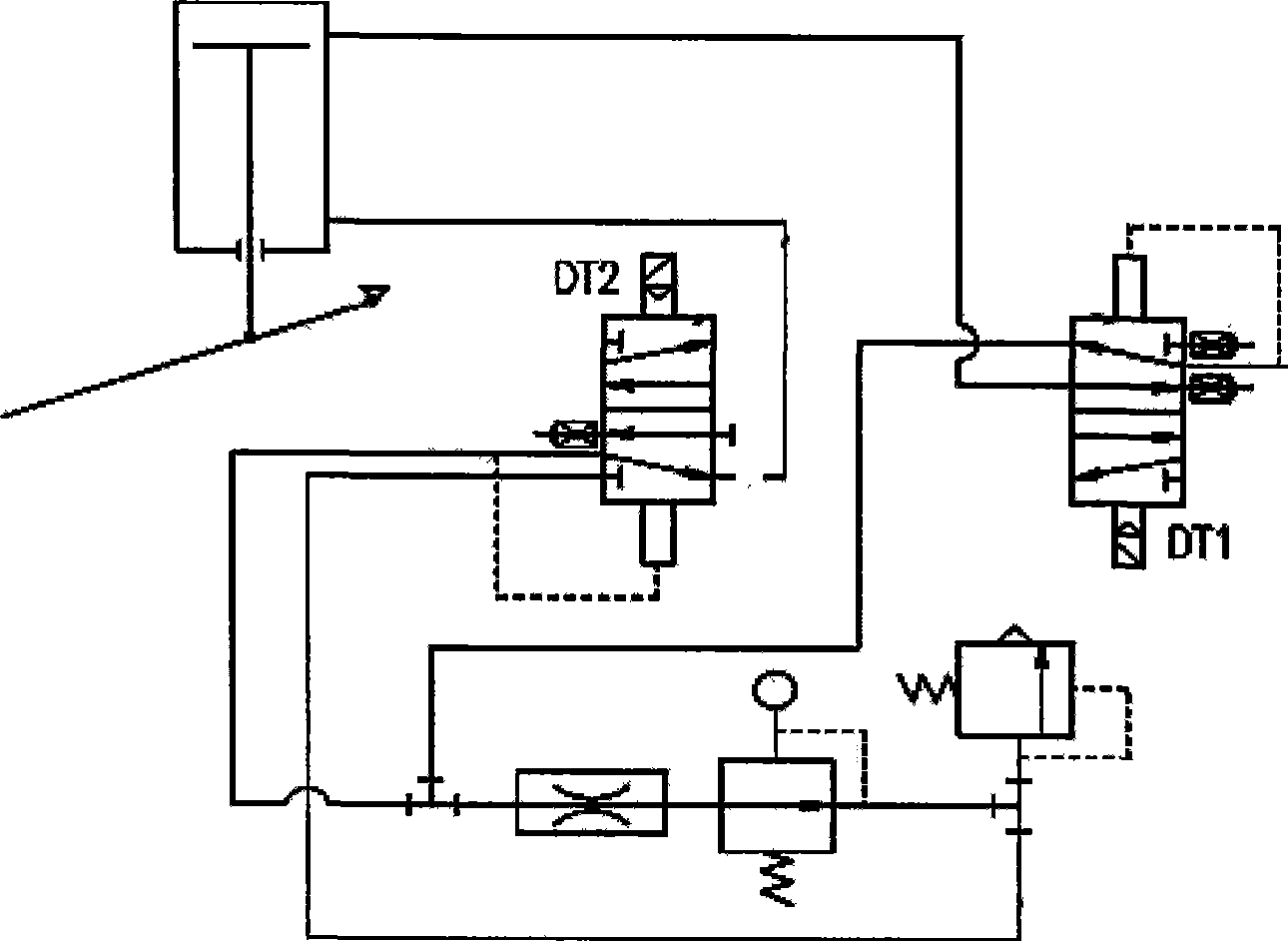

[0009] The following is attached figure 1 The present invention is further introduced: the synchronous mechanism of the slab continuous casting machine automatic flame cutting machine is composed of a water-cooled large frame, a cylinder 1, a pivot hinge seat, a compression frame 2 made of water-cooled rectangular steel pipes, and an electromagnetic valve. The solenoid valve pipeline is connected to the cylinder 1, and the cylinder 1 is installed on the water-cooled large frame. One end of the compression frame 2 is hinged to the rear of the large frame, and the other end is pushed by the cylinder 2 to compress the cast slab, so that the cutting machine can cut It runs synchronously with the slab to ensure that the slit is perpendicular to the longitudinal axis of the slab. In standby mode, both DT1 solenoid valve 3 and DT2 solenoid valve 4 are de-energized, the clamping frame is in the upper position, the brake of the cutting machine transmission is de-energized and braked, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com