Polyurethane foaming platform

A polyurethane and platform technology, applied in the field of flipping platform, can solve the problems of poor stability of foamed products, high labor intensity of workers, affecting performance, etc., and achieve the effects of improving stability, increasing use value and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] For a better understanding of the present invention, it will be further described in detail below in conjunction with the accompanying drawings and embodiments.

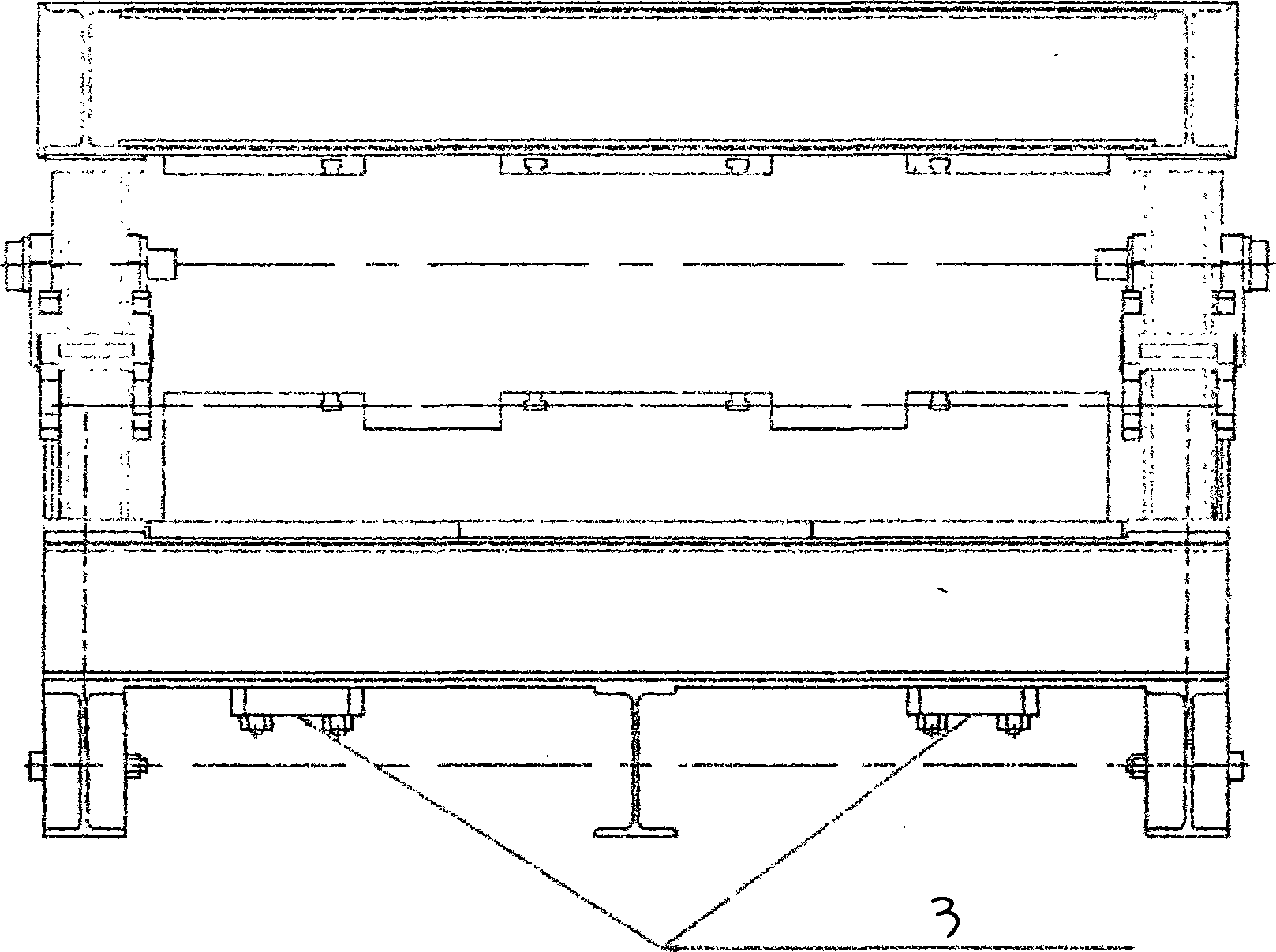

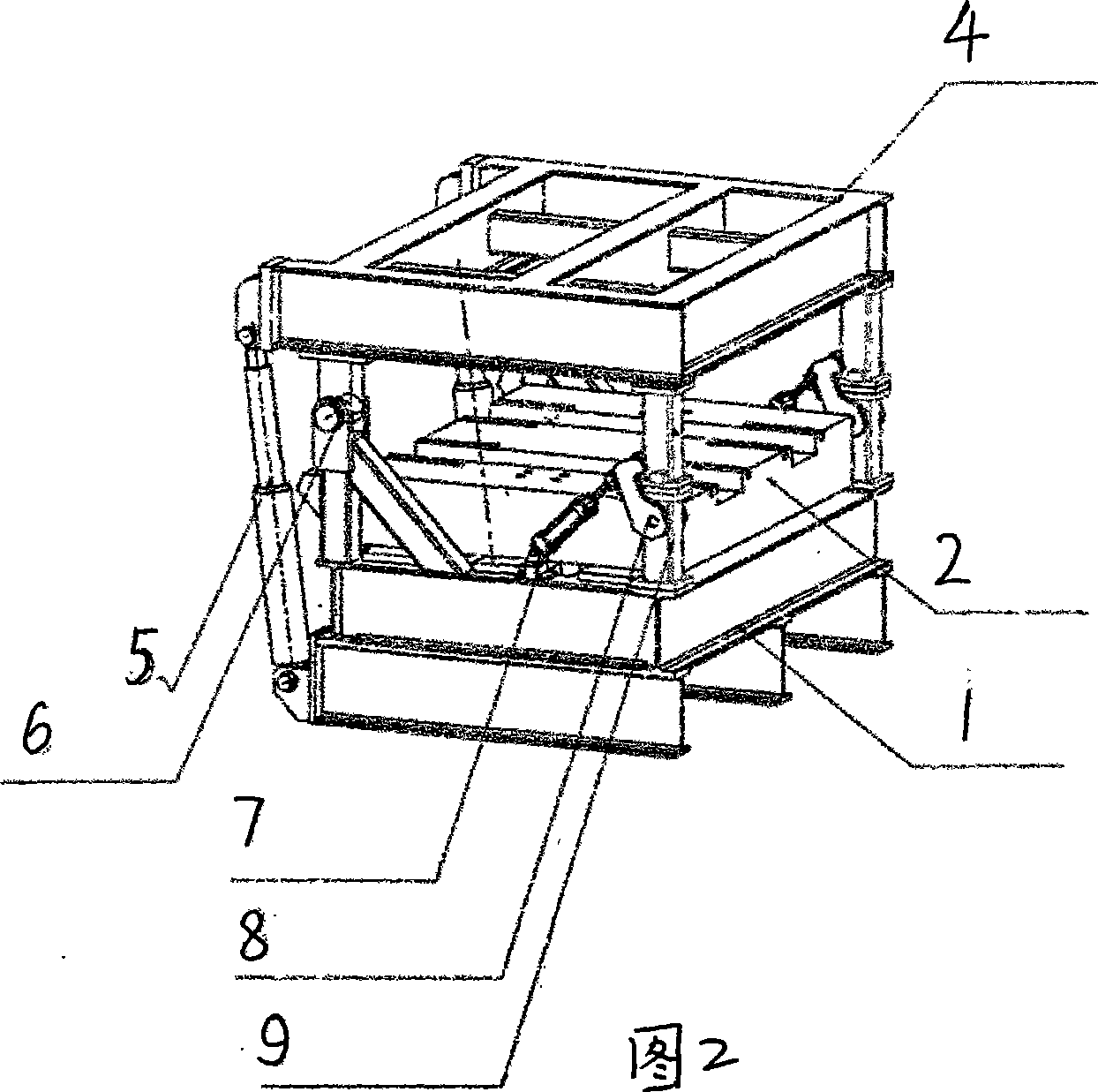

[0009] refer to figure 1 , Fig. 2 can be seen, the polyurethane foaming platform of the present invention mainly comprises the main engine that is fixedly installed on the fuselage 10 and the program-controlled operating system that is connected with the main engine, the main engine is made of upper formwork 4, lower formwork 1 and placed The movable platform 2 between the two constitutes, one end of the upper formwork 4 and the lower formwork 1 are connected to each other through two hinge columns 6, and the other end is formed by two locking cylinders 7, locking hooks 8 and pillars 9. The sleeve locking mechanism is locked and connected. The movable platform 2 is connected to the lower formwork 1 through the main oil cylinder 3. A turning cylinder 5 is respectively arranged on the fuselage outside each hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com