Die locking device for directly extruding casting die

A technology of squeeze casting and clamping device, applied in the field of squeeze casting, can solve the problems of complex action process, increase the clamping force of the mold, affect the quality of molten metal, etc., and achieve simple clamping and unlocking actions and simple action control. , structurally reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

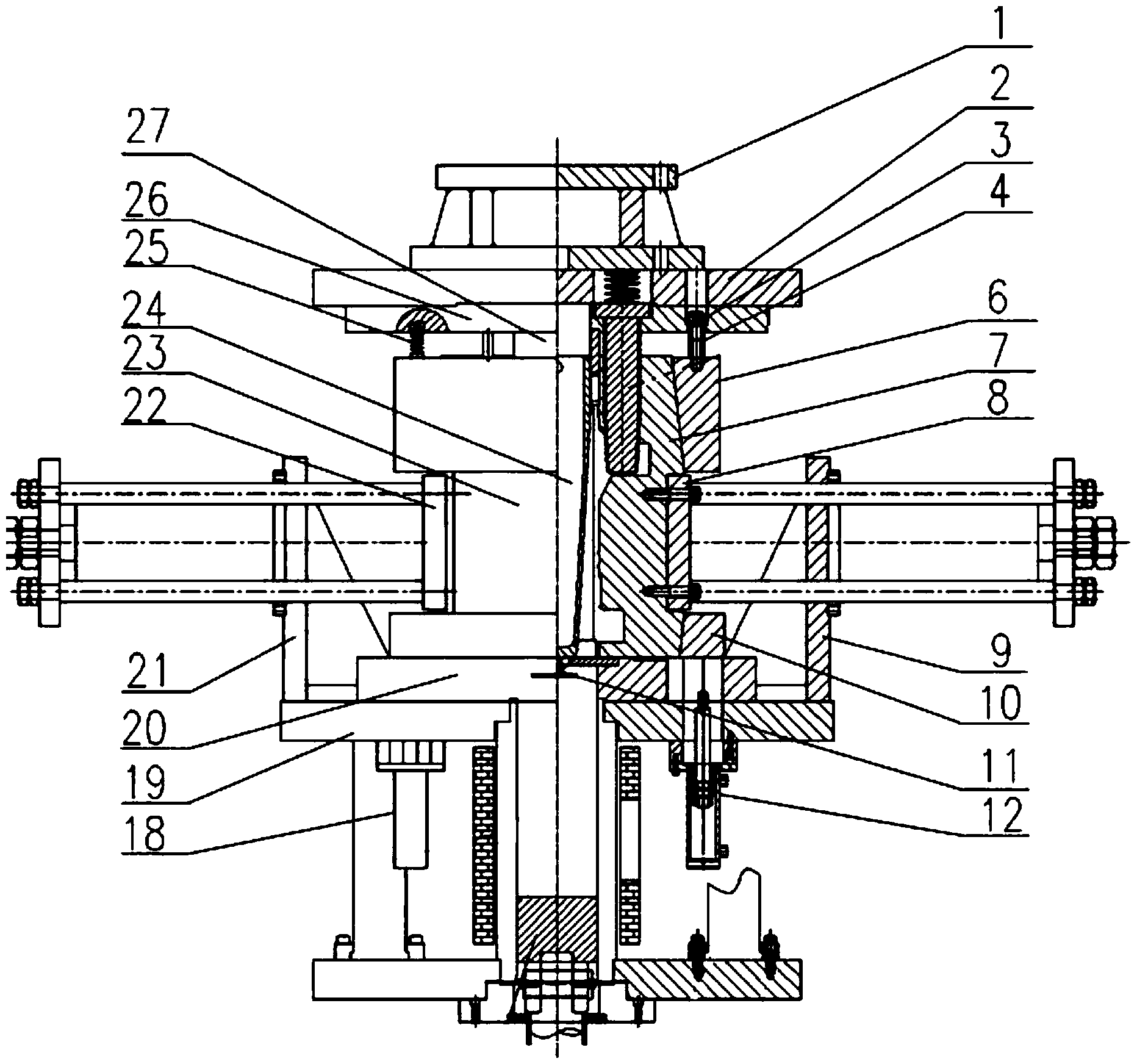

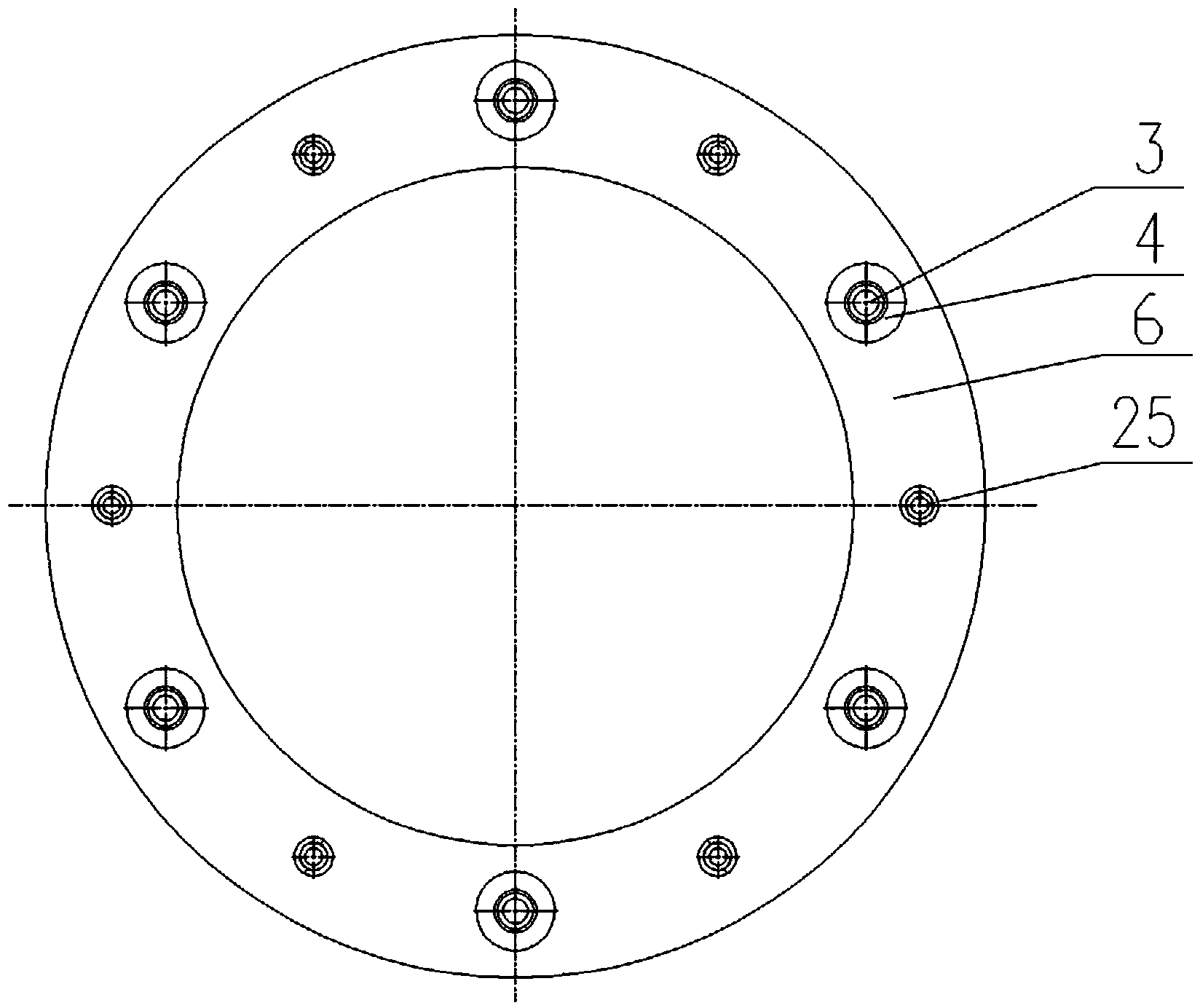

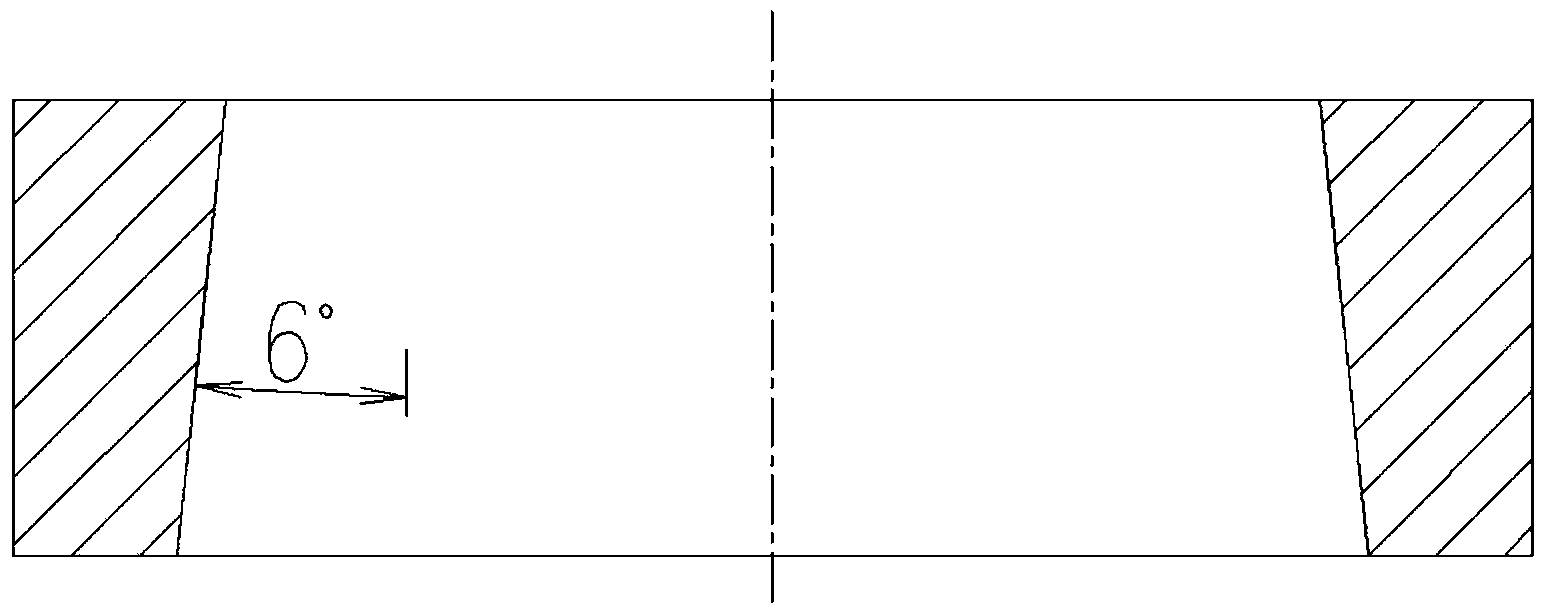

[0029] Such as figure 1 --3 shown. The clamping device of the direct squeeze casting mold of the present invention comprises a left side mold 23, a right side mold 7, a press worktable 19, and an upper mold plate 26; The upper mold clamping ring 6 and a lower mold clamping ring 10 sleeved on the outside of the right mold 7 and the left mold 23, the inner surface of the upper mold clamping ring 6 and the lower mold clamping ring 10 are in contact with the left mold 23 It is consistent with the angle of the tapered surface at the fitting position of the right mold 7, so that the molds can cooperate with each other when fitting to form a self-locking angle.

[0030] The clamping device also includes a right drive cylinder 12 and a left drive cylinder 18 for driving the lower clamping ring 10 to move;

[0031] The right drive cylinder 12 and the left drive cylinder 18 are symmetrically distributed and fixedly installed on the press worktable 19,

[0032] The lower clamping ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com