On site precision detecting test line for high-voltage current transformer

A high-voltage current and test circuit technology, which is applied in the direction of instruments, measuring devices, and measuring electrical variables, can solve problems such as the cost of voltage regulators, the difficulty of manufacturing technology, the difficulty of ensuring compensation capabilities of capacitors, and the reduction of compensation capabilities. To achieve the effect of reducing the capacity of the test power supply, reducing the number, and reducing the rated voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

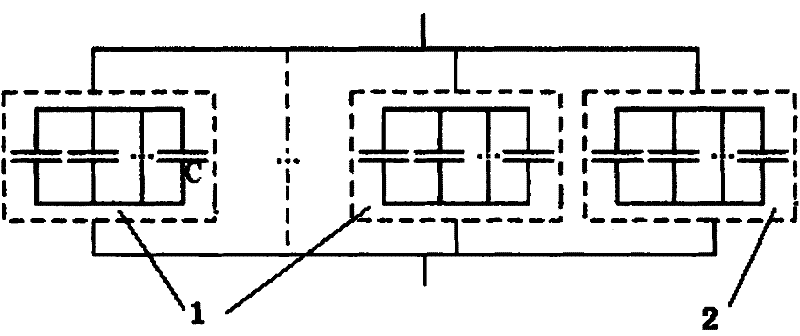

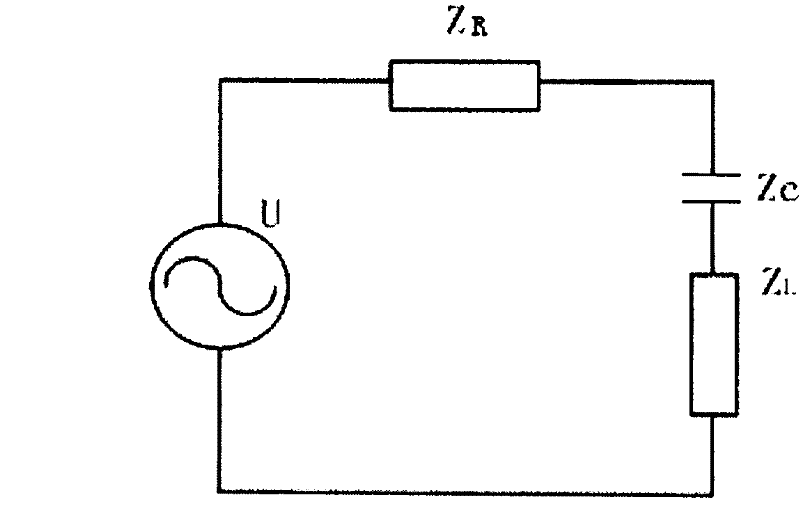

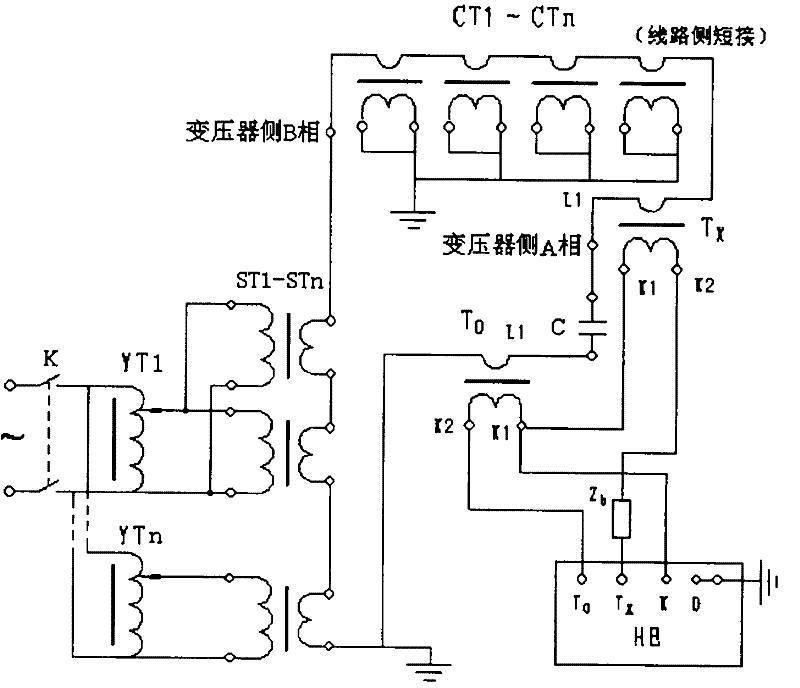

[0019] refer to figure 1 , the high-voltage current transformer on-site accuracy detection test circuit includes voltage regulator T1, current booster T2, compensation capacitor C, test power supply AC electrically connected to the primary side of voltage regulator T1, inductance L and resistance R of the main circuit , the compensation capacitor C is connected in series in the main circuit for series compensation; the voltage of the test power supply AC is reduced after passing through the voltage regulator T1, and then electrically connected to the primary side of the current booster T2, and the secondary side of the current booster T2 is connected to the main circuit circuit It is used to generate the large current required for calibration of the standard current transformer and field current transformer set on the main circuit. Adjusting the voltage on the secondary side of the voltage regulator T1 can adjust the size of the current flowing into the main circuit, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com