Electrostatic clamping disc controlling temperature by air and method for controlling temperature of substrate

An electrostatic chuck and gas temperature technology, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of large energy loss and slow temperature control speed, and achieve the effect of small energy loss and fast temperature control speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

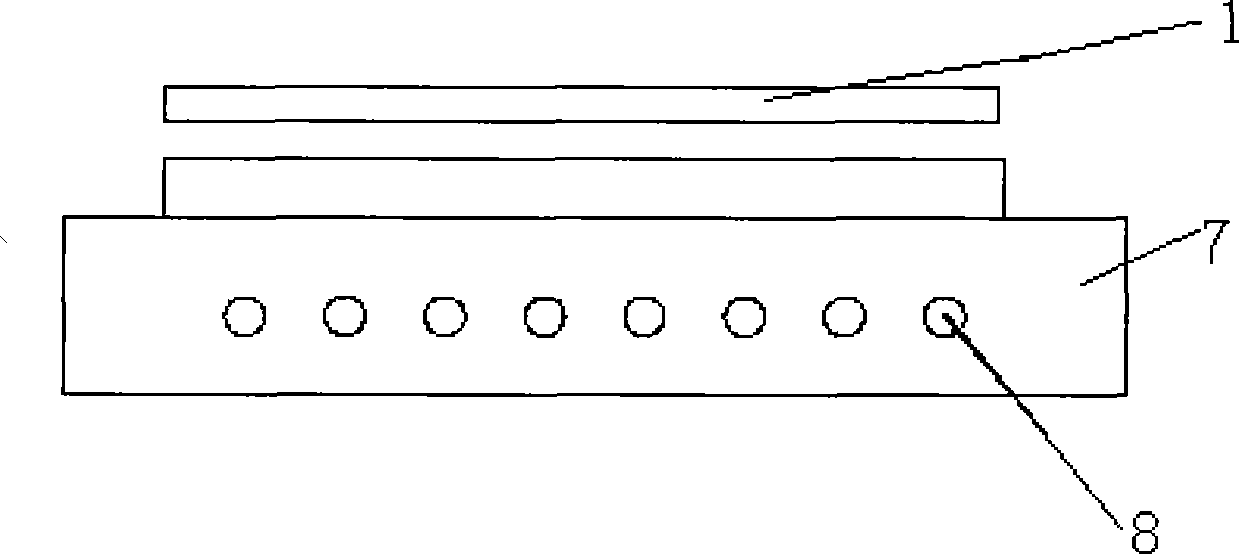

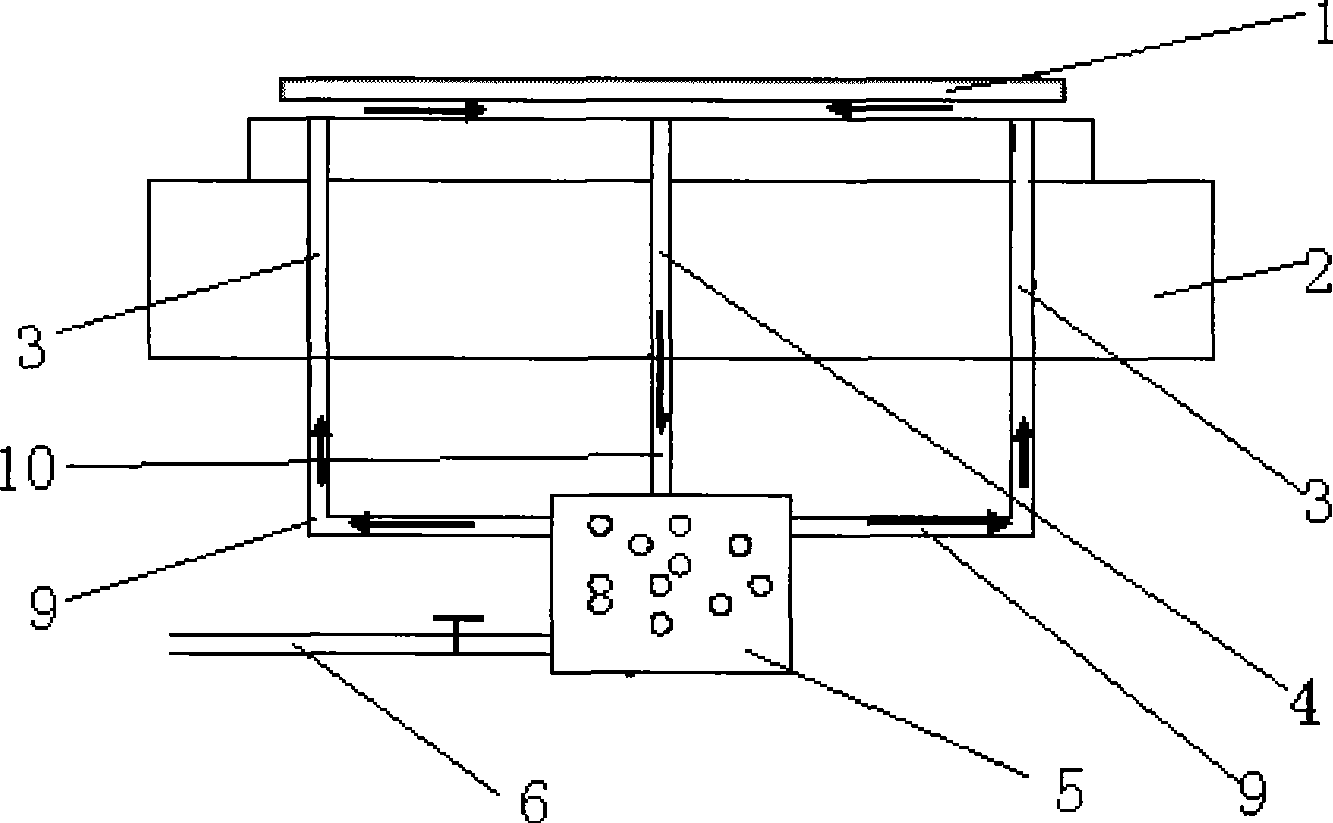

[0013] The gas temperature-controlled electrostatic chuck of the present invention, its preferred embodiment is as follows figure 2 As shown, the electrostatic chuck 2 is provided with a plurality of through holes 3, 4 communicating up and down, the lower end of at least one of the plurality of through holes 3, 4 is connected with an air supply channel 9; the lower end of at least one through hole Connected with return air channel 10. During the process, gas at a required temperature can be introduced through the gas supply channel 9 and flow back through the return gas channel 10 to form a circulation between the electrostatic chuck 2 and the substrate 1 to directly control the temperature of the substrate 1 . The temperature control speed is fast and the energy loss is small.

[0014] The gas supply channel 9 can be connected with a gas temperature control device 5, and the gas temperature control device 5 controls the temperature of the gas to make the gas reach a require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com