LED and its making method

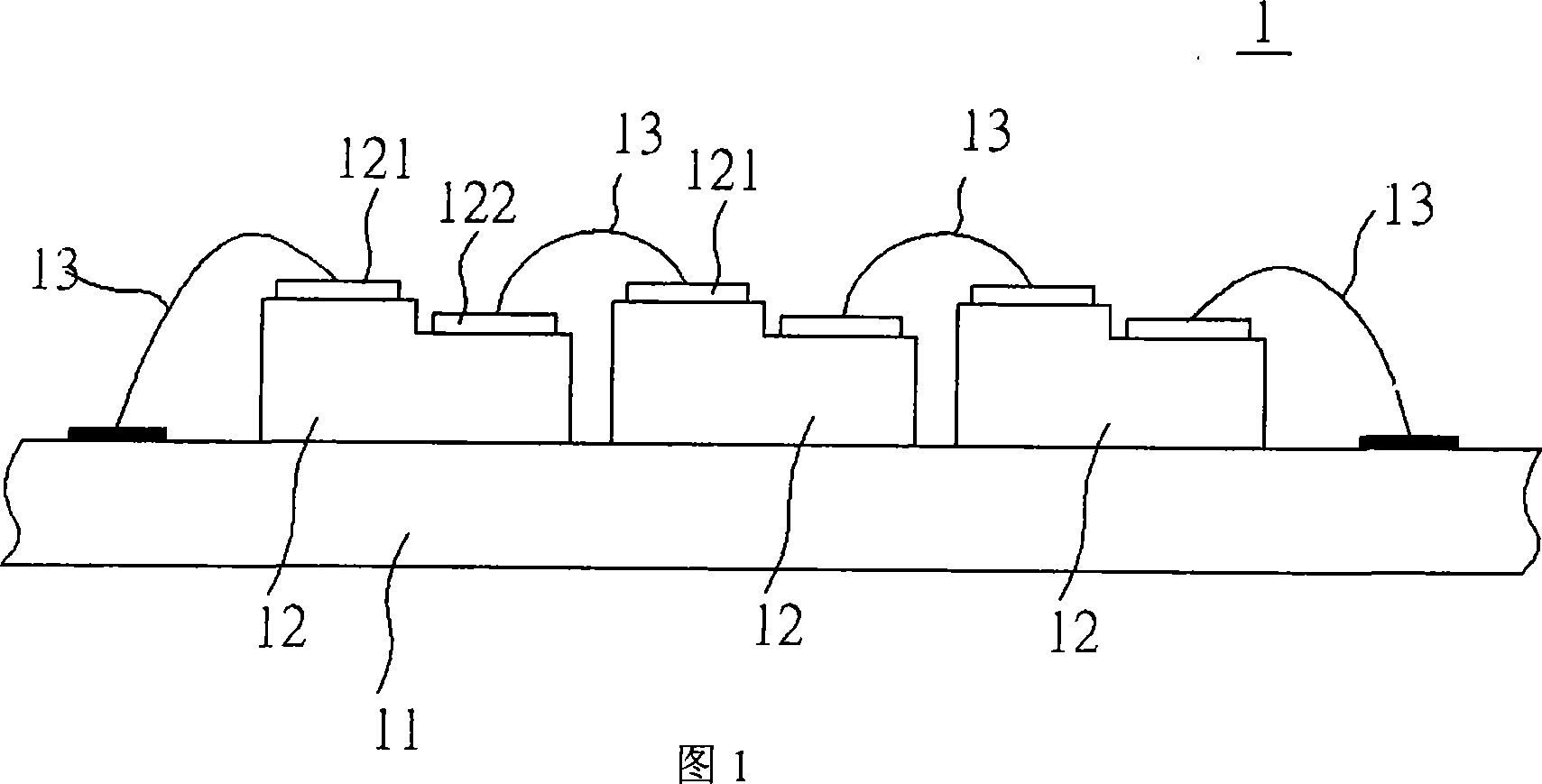

A technology of light-emitting diodes and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., and can solve the problems that light-emitting diodes cannot use high brightness, wires 13 are detached, and the defect rate increases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make your examiner understand the main technical content and implementation mode of the present invention, the description is as follows with the help of drawings:

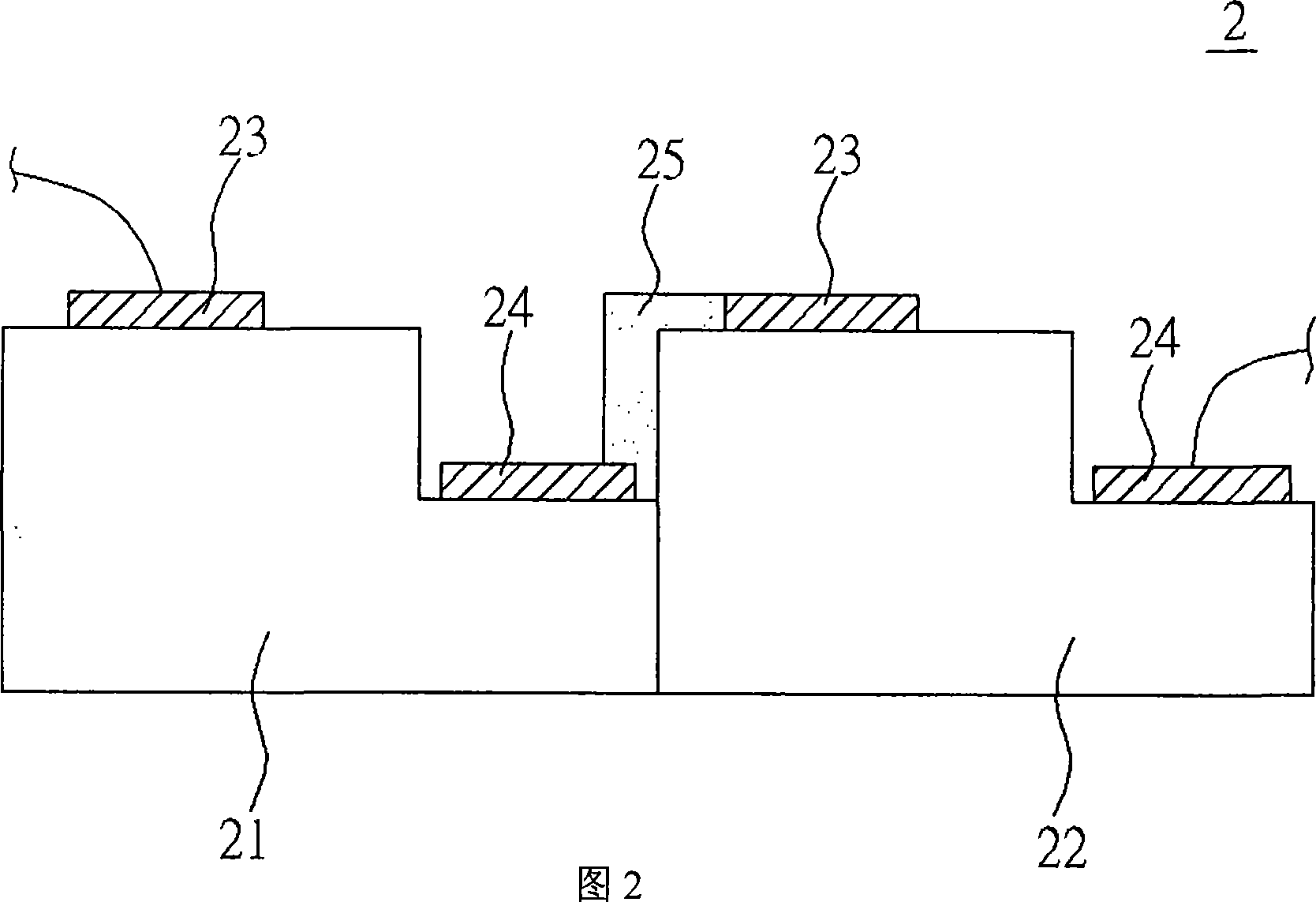

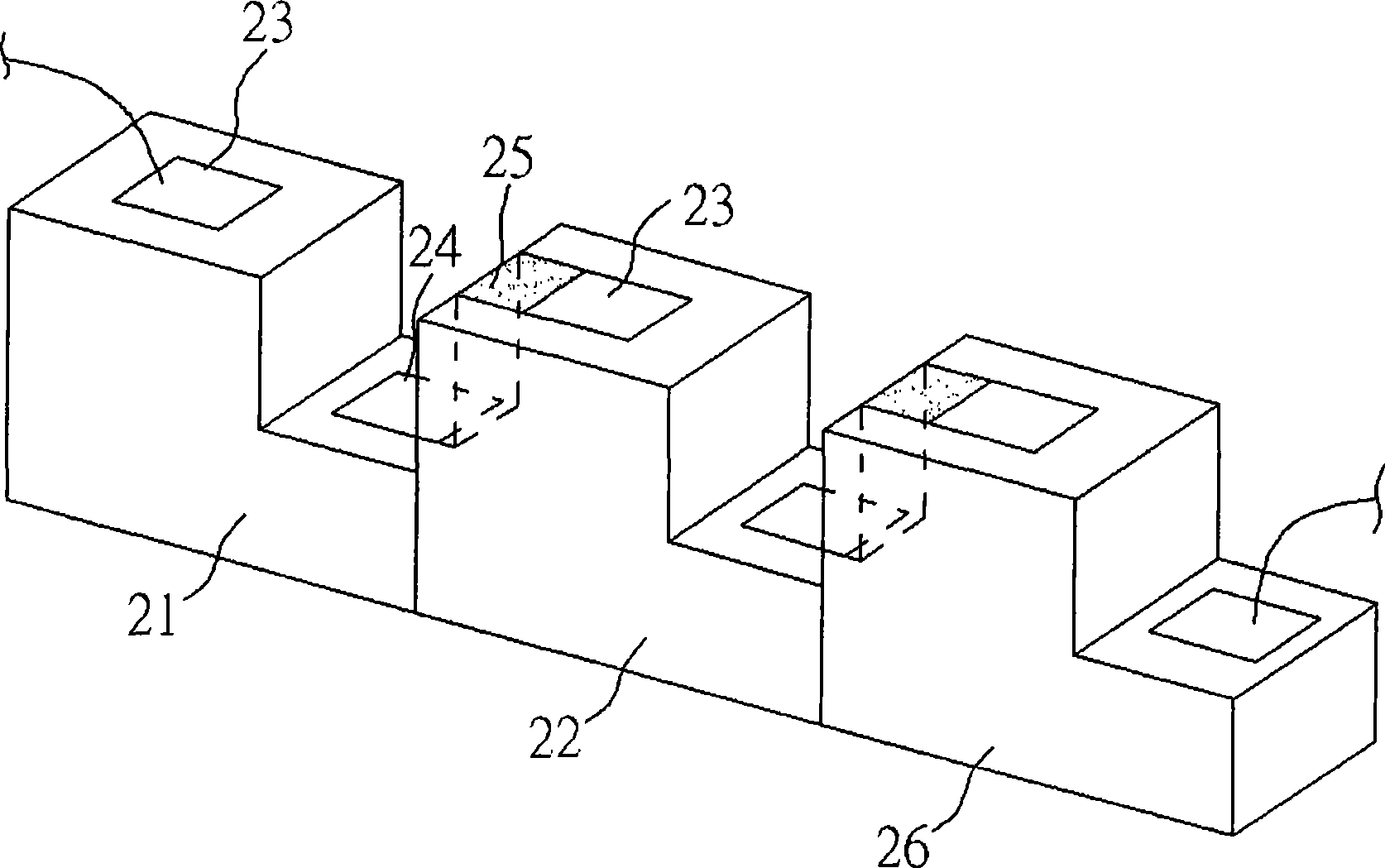

[0030] The light-emitting diode of the present invention and its manufacturing method, as shown in Figure 2, the light-emitting diode 2 is provided with at least a plurality of light-emitting chips, as shown in the figure is provided with first and second light-emitting chips 21,22, each light-emitting chip 21,22 surface There are separated positive and negative poles 23 and 24, and the two light-emitting chips 21 and 22 are arranged continuously, wherein the negative pole 24 of the first light-emitting chip 21 is close to the positive pole 23 of the second light-emitting chip 22, and the positive pole of the first light-emitting chip can also be approached. The negative electrode of the second light-emitting chip.

[0031] Among them, the negative and positive electrodes 24 and 23 of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com