Pixel structure and method of manufacture

A technology of pixel structure and pixel electrode, which is applied in semiconductor/solid-state device manufacturing, photolithographic process exposure device, optics, etc. It can solve the problems of decreased aperture ratio, affecting brightness performance, and enhanced crosstalk effect, so as to improve aperture ratio, The effect of increasing brightness performance and reducing coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

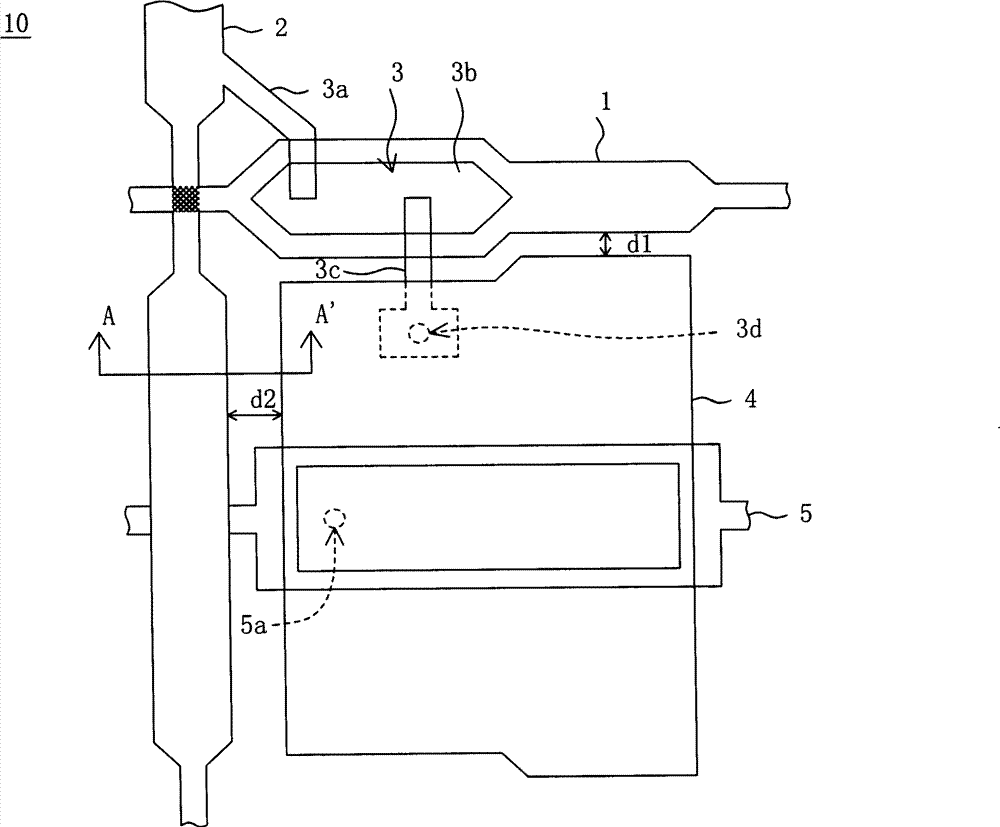

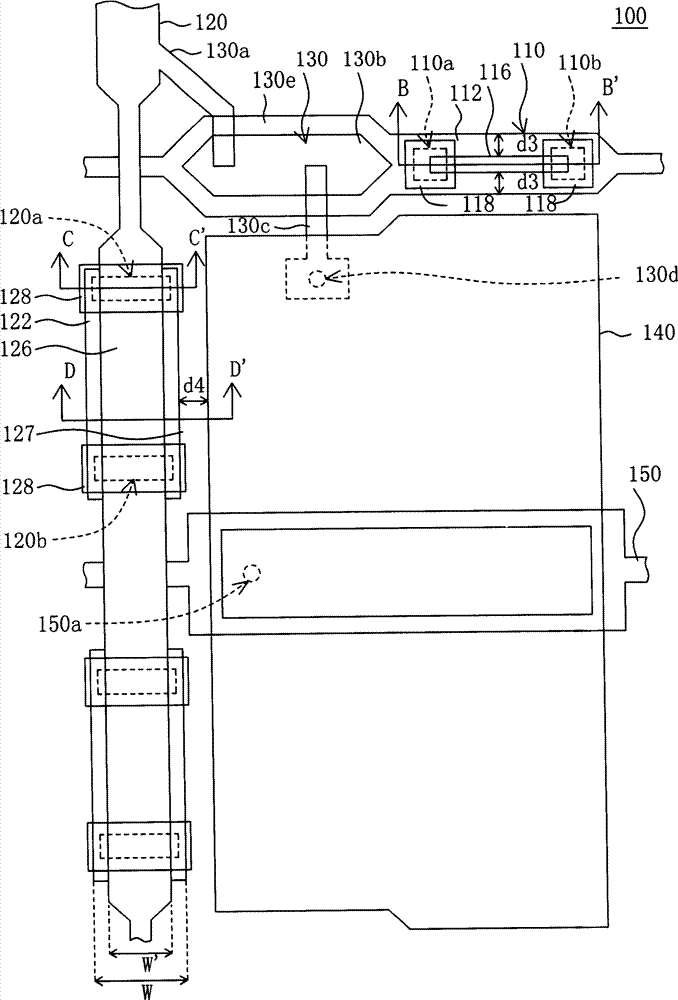

[0058] Please refer to Figure 2A, which is a schematic diagram of a pixel structure according to Embodiment 1 of the present invention. The pixel structure 100 includes scan lines 110 , data lines 120 , thin film transistors 130 , pixel electrodes 140 and storage capacitors 150 . The thin film transistor 130 is disposed on the scan line 110, and a part of the scan line 110 is used as the gate 130e of the thin film transistor 130 to control its switching. The data line 120 is coupled to the source 130a of the thin film transistor 130. When an appropriate voltage is applied to the scanning line 110, the signal can be transmitted through the channel layer 130b, and output from the drain 130c to the pixel electrode 140 through the contact hole 130d. The storage capacitor 150 is coupled to the pixel electrode 140 through the contact hole 150 a for maintaining the voltage of the pixel electrode 140 .

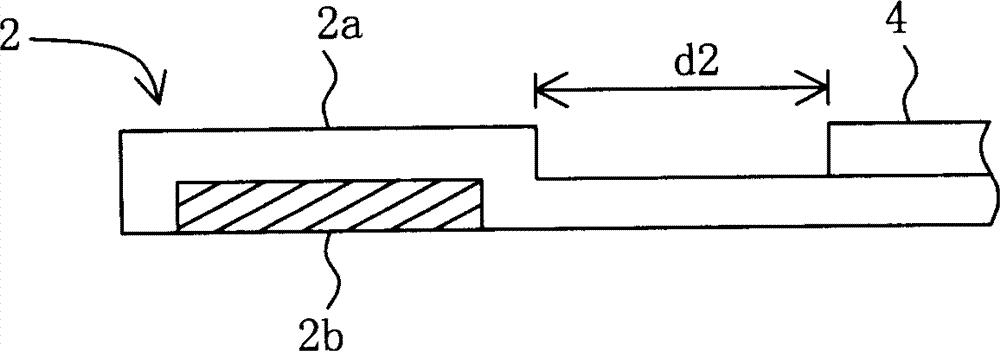

[0059] Please refer to Figure 2B , which is shown as Figure 2A The cross-s...

Embodiment 2

[0080] Please refer to Figure 7A , which is a schematic diagram of a pixel structure in Embodiment 2 of the present invention. The main difference between the pixel structure 200 and the pixel structure 100 of the first embodiment lies in the types of the contact holes in the scan line 210 and the data line 220, and the rest of the elements are the same as those of the first embodiment, and their labels will continue to be used and will not be repeated. The link is off.

[0081] Please refer to Figure 7B , which shows Figure 7A The cross-sectional view of the middle scan line along the section line EE'. The first scanning insulating layer 213 and the second scanning insulating layer 217 respectively have a first contact hole 210a and a second contact hole 210b, and the third scanning metal layer 218 is respectively connected to the first contact hole 210a and the second contact hole 210b. One end of the scanning metal layer 112 and the second scanning metal layer 116 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com