Valve

A valve and valve body technology, applied in valve details, valve device, valve shell structure, etc., can solve the problems of weak connection, rotation, easy separation of the plastic pipe from the valve, etc., to increase the connection strength, simplify the structure, and improve the sealing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

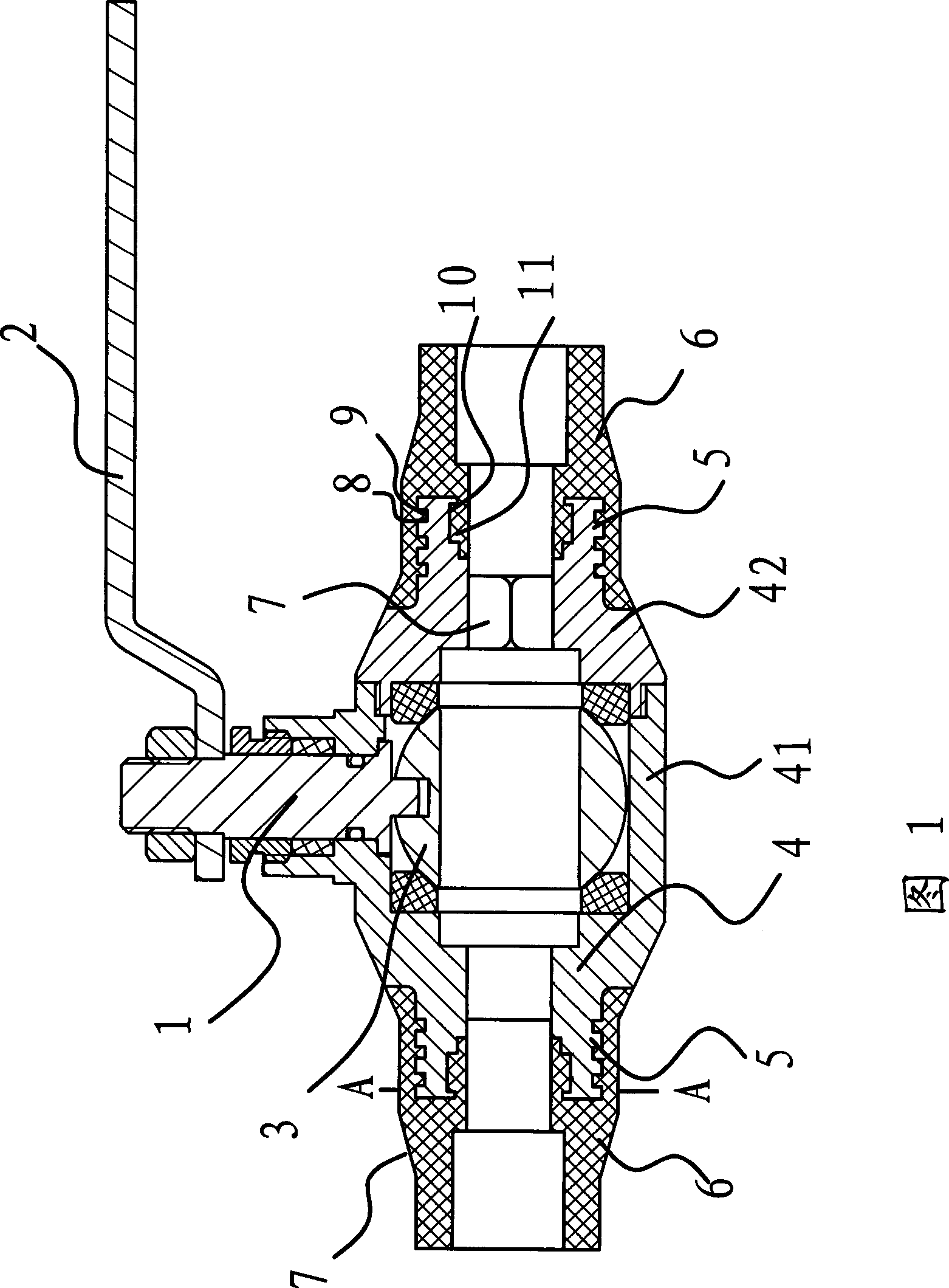

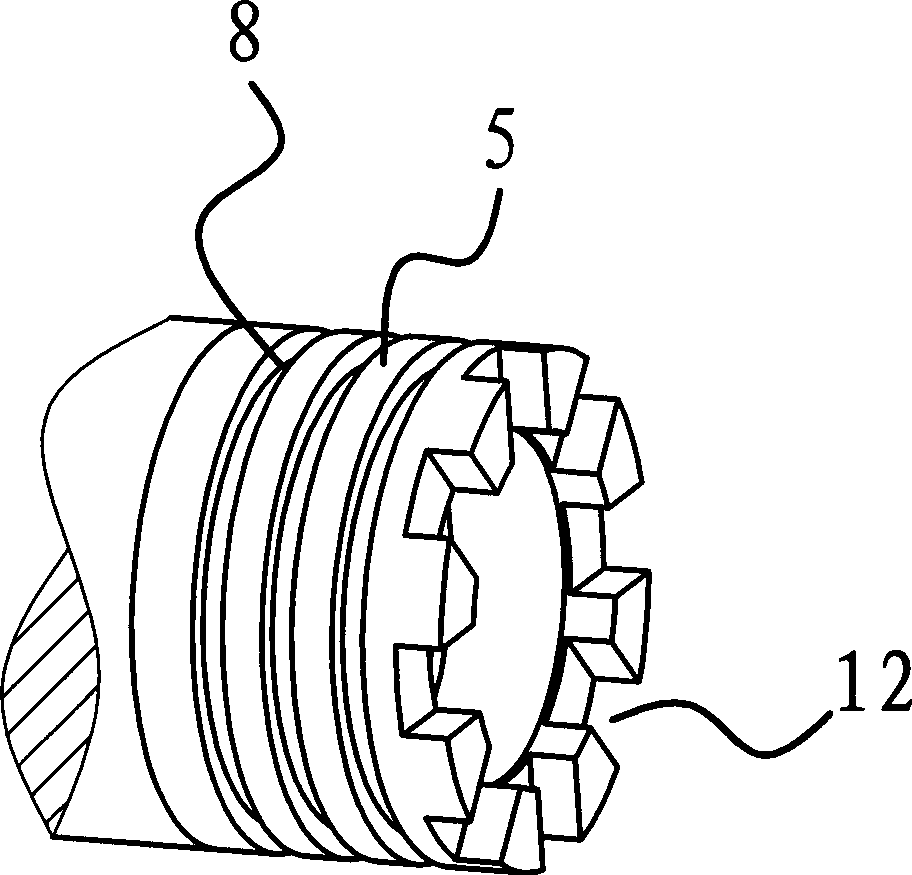

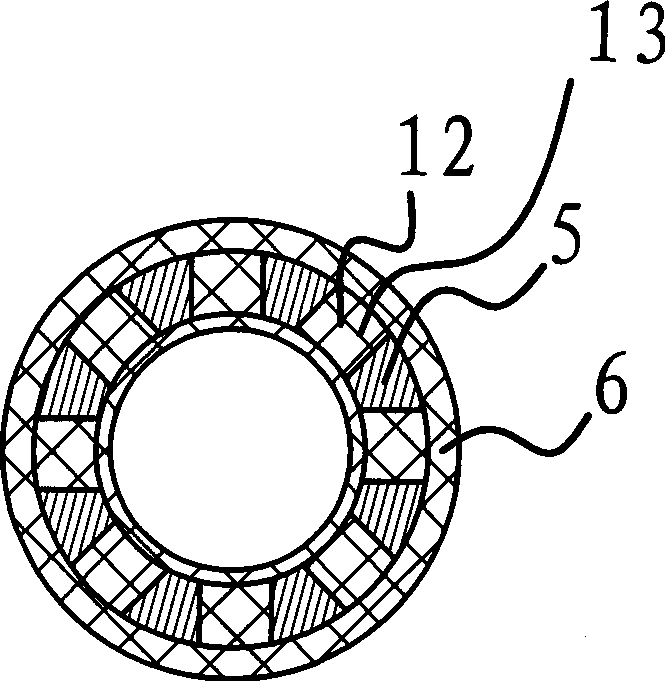

[0024] As shown in Figure 1, the valve includes a valve stem 1, a handle 2, a valve core 3 arranged in a valve body 4, and a valve body 4 made of metal material. One end of the valve stem 1 is connected to the valve core 3, and the other end is Pass through the valve body 4 and connect with the handle 2. The end of the valve body 4 has a water pipe 5, and the water pipe 5 is provided with a connecting pipe 6 made of plastic. The material used for the plastic is PPR. Directly connect the connecting pipe 6 to the end of the water pipe 5 . The two ends of the water pipe 5 of this valve are connected with the upper connecting pipe 6 to facilitate the connection with other plastic pipe fittings.

[0025] Specifically, in order...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap