Hybrid filter element and method

A filter element and element technology, which is applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of low efficiency of solvent treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

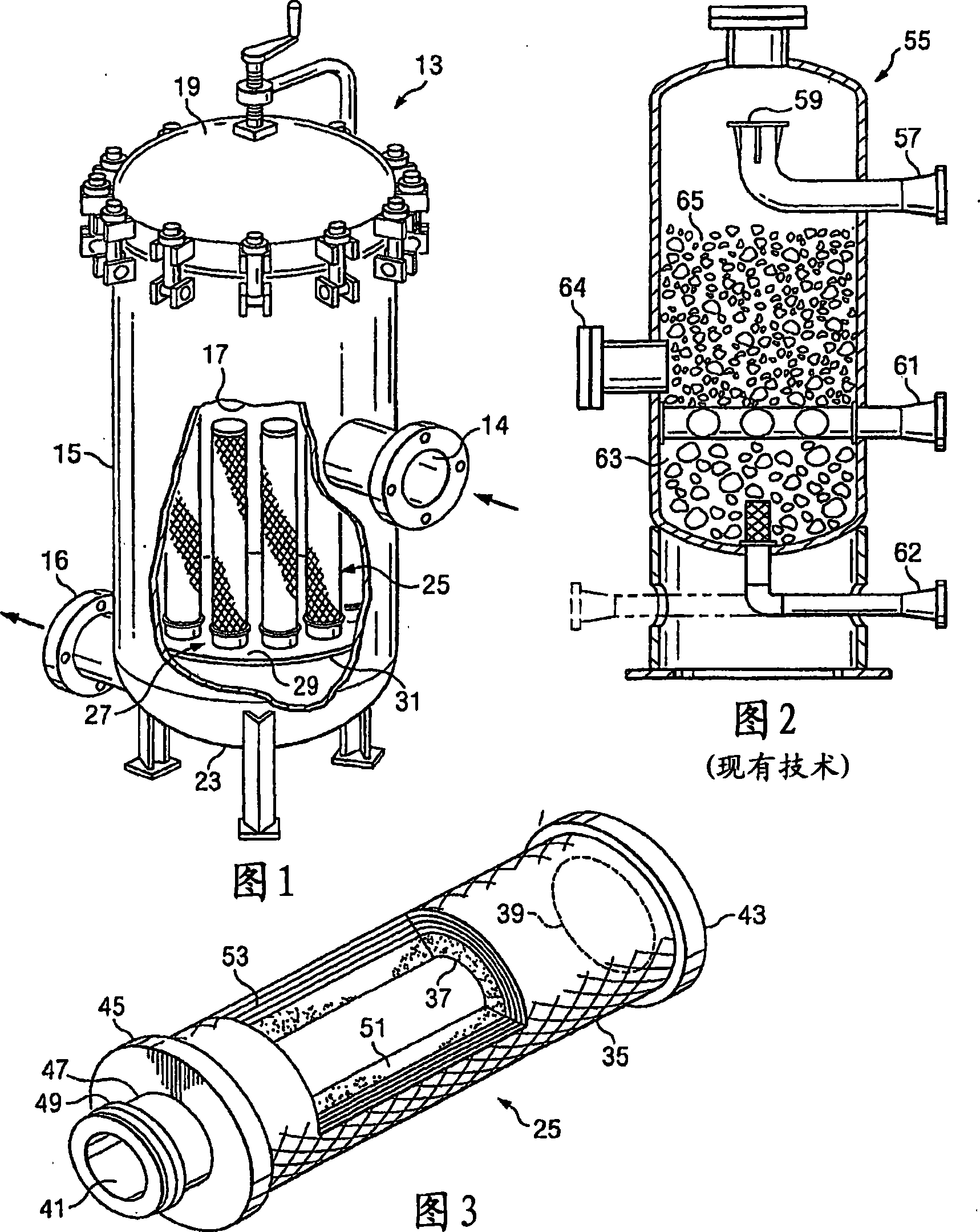

[0026] The particular type of filter vessel to which the improved filter element of the present invention is applied may take a variety of configurations. For example, those familiar with the oil and gas manufacturing industry will be familiar with filter vessels that contain filtration for filtering a dry gas stream and for separating solid particles and liquids from the stream containing contaminants. element. These types of vessels are often installed in gas lines to perform their filtering function. U.S. Patent No. 5,919,284, issued July 6, 1999, and U.S. Patent No. 6,168,647, issued January 2, 2001, both to Perry, Jr. and assigned to the assignee of the present invention, which Two patents disclose filter vessels that use separate filter elements to separate solid particles, filter liquids, and coalesce liquids. The aforementioned multi-stage vessels, as well as many other similar filter vessels used in the industry, employ solid or hollow core tubular elements, usually...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com