Fastening hook for adjustment

A clasp and clasp base technology, which is applied in the direction of fasteners, applications, hook fasteners, etc., can solve the problems of unusable, poor appearance of the waist, and complicated hook replacement operations, so as to reduce the number of parts and cut down cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

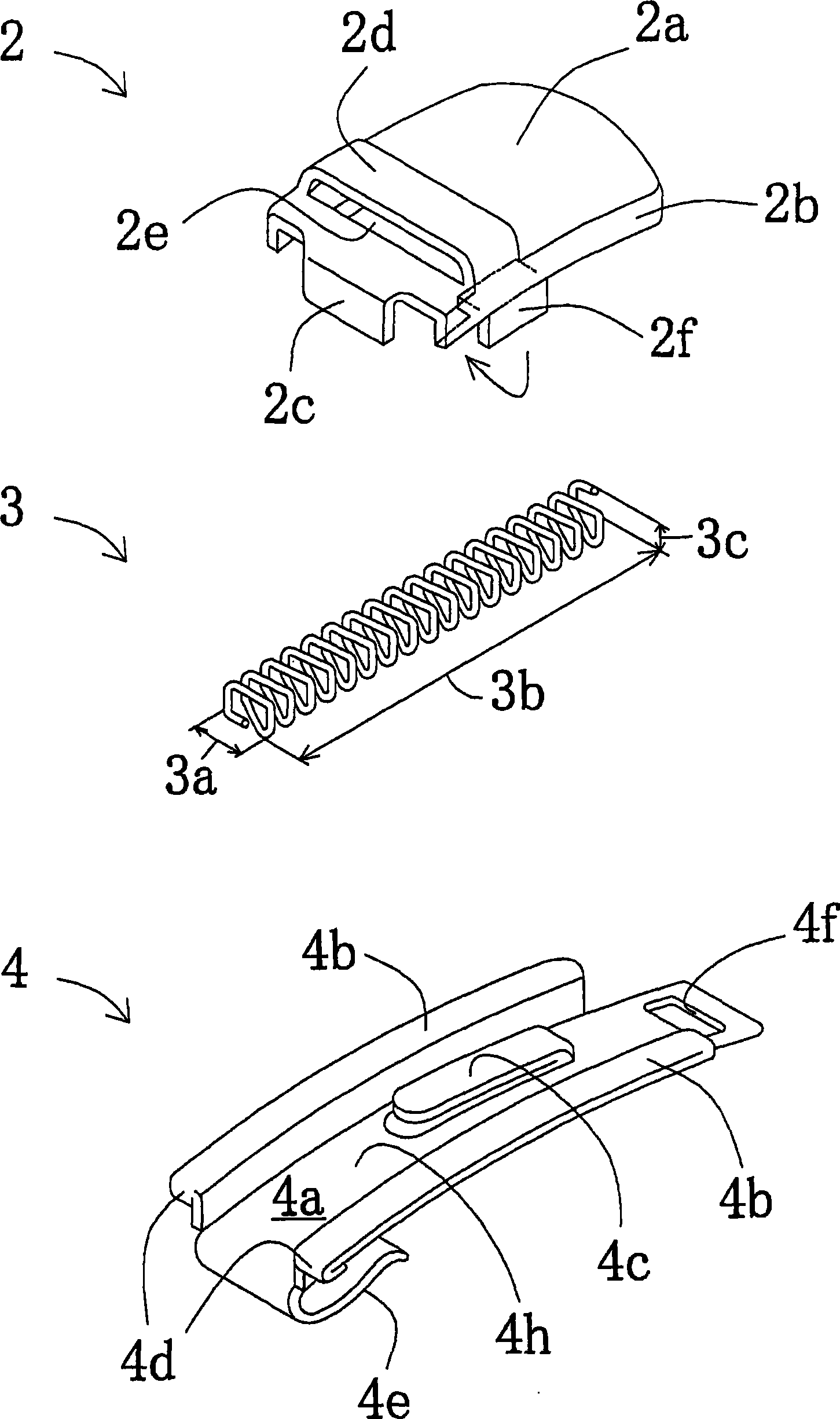

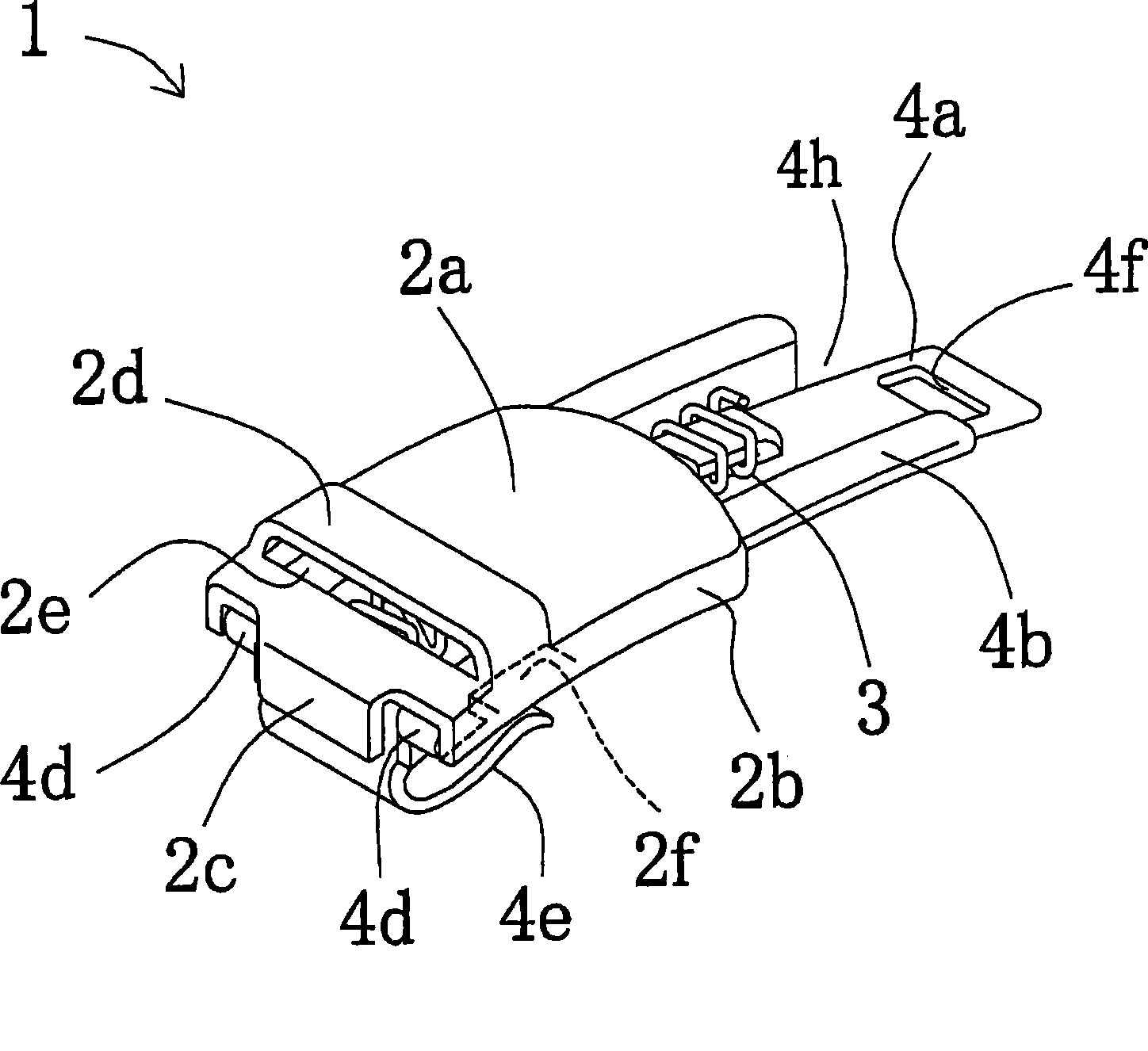

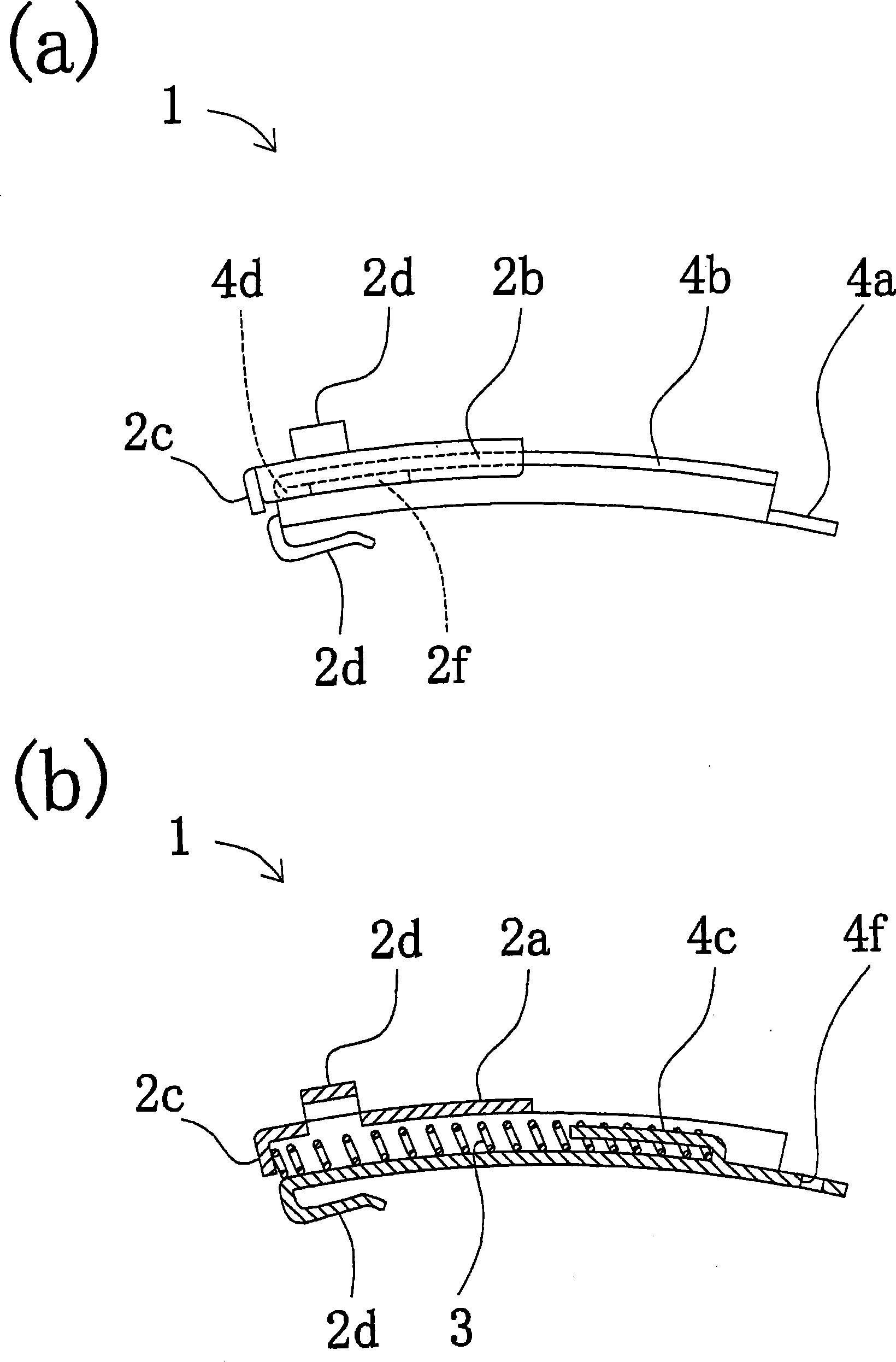

Method used

Image

Examples

Embodiment 2

[0083] Below, according to Figure 6 to Figure 8 The adjustment hook 6 according to the second embodiment of the adjustment hook of the present invention will be described. The invention of the second embodiment has substantially the same functions and effects as those of the first embodiment, but differs in the structure of the adjustment hook 6 .

[0084] The clasp main body 7 having the female hook 7d has substantially the same structure as the clasp main body 2 of the first embodiment, but the installation position of the protruding piece 7c abutting against the spring 8 is different.

[0085] like Figure 6 As shown, the substrate 7a on the substantially central side of the female hook 7d is bent vertically downward to form the protruding piece 7c.

[0086] The clasp base body 9 having the male hook 9e has substantially the same structure as the clasp base body 4 of the first embodiment, but the installation position of the male hook 9e is different.

[0087] like Figu...

Embodiment 3

[0101] Below, according to Figure 10 to Figure 15 The adjustment hook 10 according to the third embodiment of the adjustment hook of the present invention will be described. The invention of the third embodiment achieves substantially the same functions and effects as those of the first and second embodiments, but differs in the structure of the adjustment clasp 10 .

[0102] The clasp main body 11 has substantially the same structure as the clasp main body 2 of Example 1, but differs in that it does not have the female hook 2d but has the male hook 11d. like Figure 10 As shown, the male hook 11d is arranged as follows: the end of the base plate 11a opposite to the protruding piece 11c is extended above the clasp main body 11, and forms a substantially J-shape toward the protruding piece 11c. Thus, if Figure 13 and Figure 14 As shown, it can be installed on the trousers female hook 5e of the trousers 5. Additionally, if Figure 12 As shown, the substrate 11a has a ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com