Mechanism for shearing steel bar straightening and shearing machine

A technology of shearing mechanism and cutting machine, which is applied in the field of shearing mechanism, can solve the problems of inability to cut steel bars, increase the cost of use, waste of raw materials, etc., and achieve the effect of avoiding repeated friction and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] The specific implementation, non-limiting examples are as follows:

Embodiment

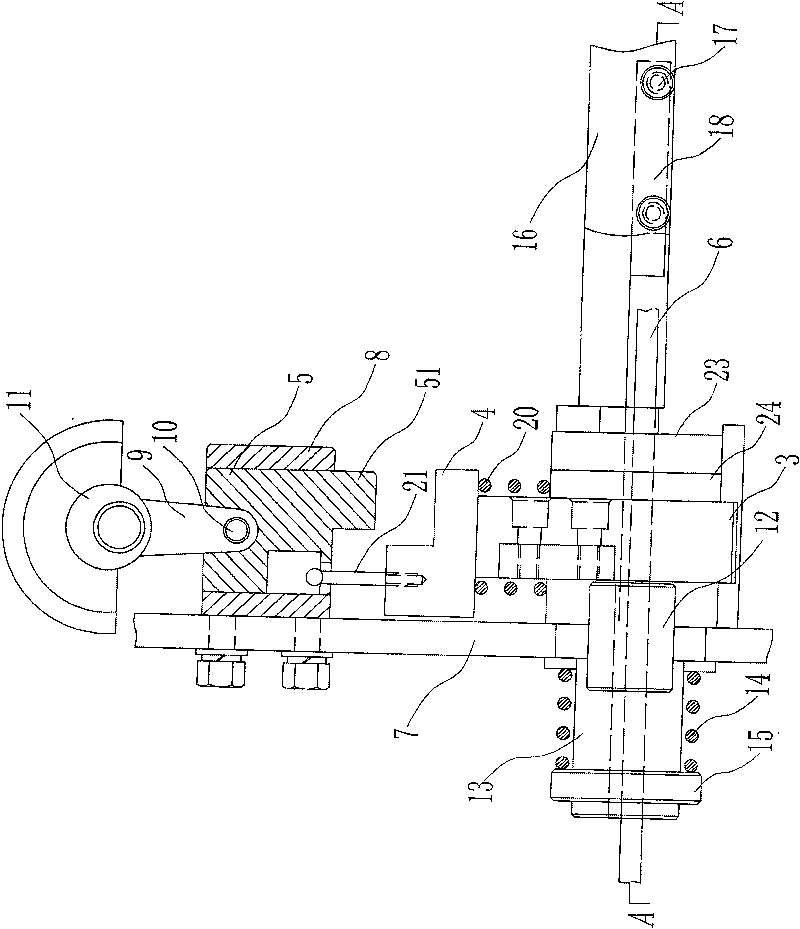

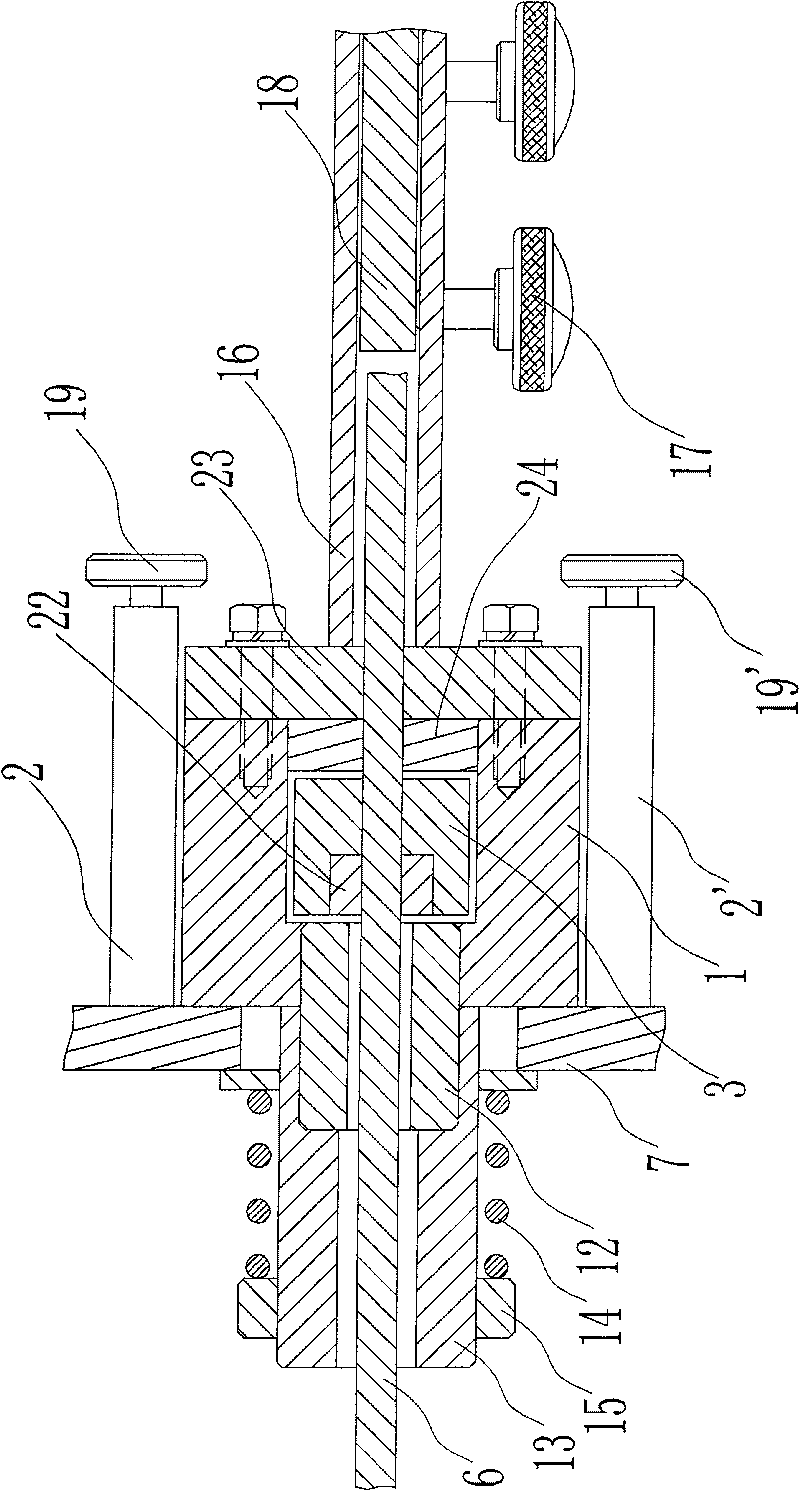

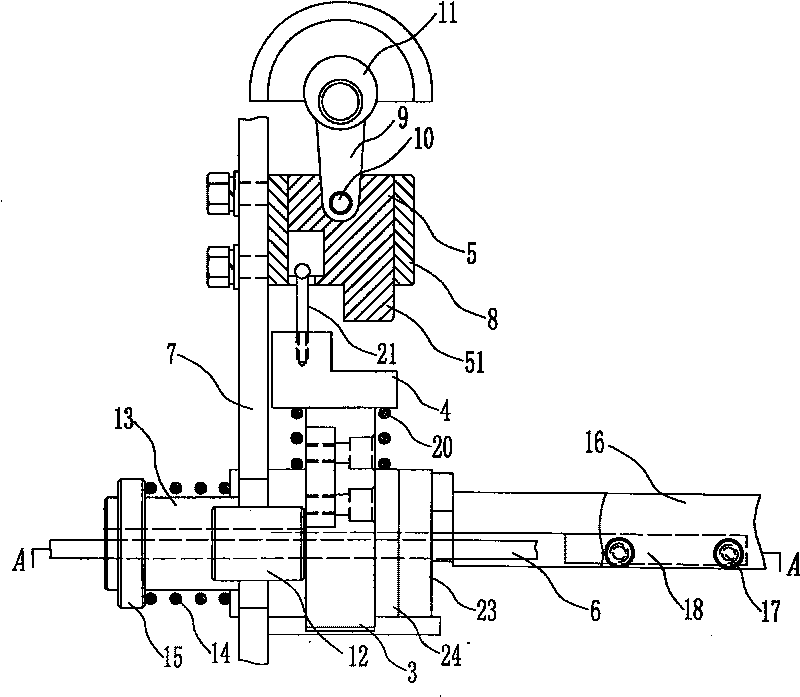

[0024] Example: figure 1 , 2 As shown, in the shearing mechanism used in the steel bar straightening and cutting machine described in this embodiment, the shearing seat 1 is arranged between the two parallel groove plates 2, 2' of the frame to ensure that it can move linearly from side to side. , the cross-section of the shearing seat is in the shape of a "mouth", the lower end of the movable knife body 3 extends to the inner cavity of the shearing seat and can perform longitudinal reciprocating movement in the inner cavity, and the upper end of the movable knife body 3 is threaded (of course, it can also be keyed. connection or other forms of fixed connection) at the lower end of the receiving seat 4, the receiving seat is "L" shaped, and the punch block 51 at the lower end of the punching seat 5 in the non-shearing state does not impact the receiving seat 4, and when the shearing state is When the receiving seat 4 moves a certain distance to the right, the punching block 51...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com