Shearing force measurement bridge circuit in bending-twisting combined test apparatus

A combination of test device and bending torsion technology, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problems of large measurement error and bending normal stress that cannot be eliminated, so as to improve measurement accuracy, enrich experimental teaching content, and increase thinking and fun effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

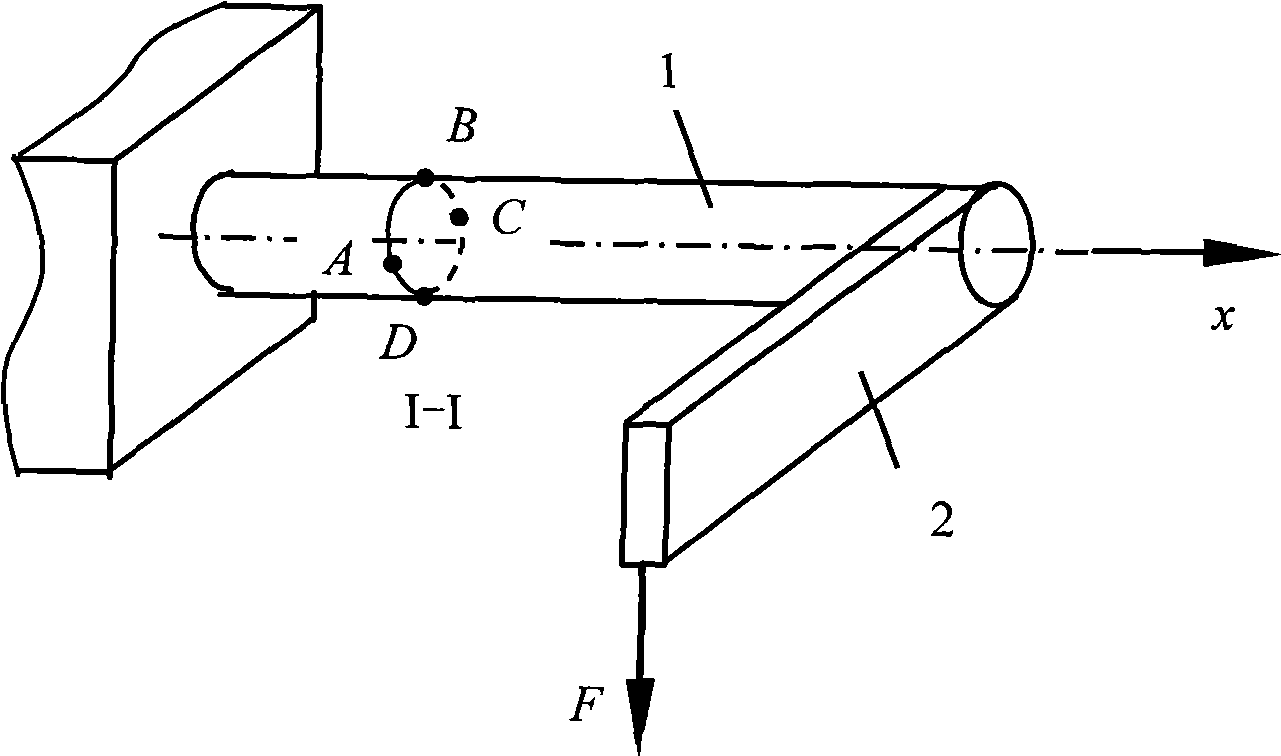

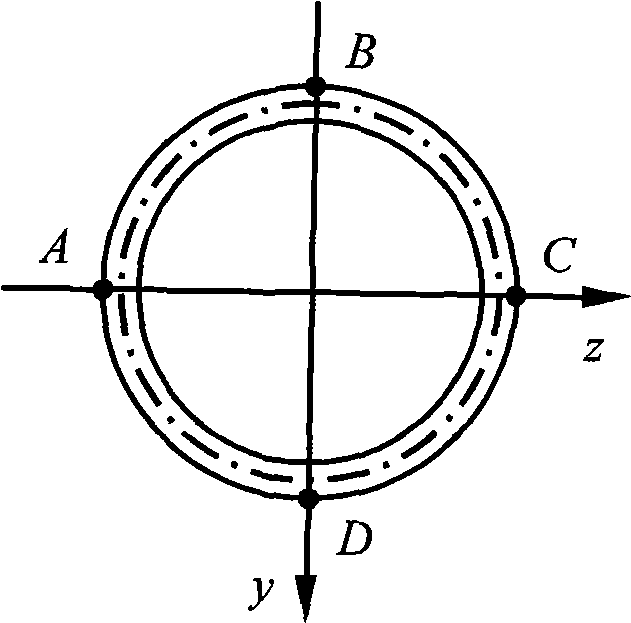

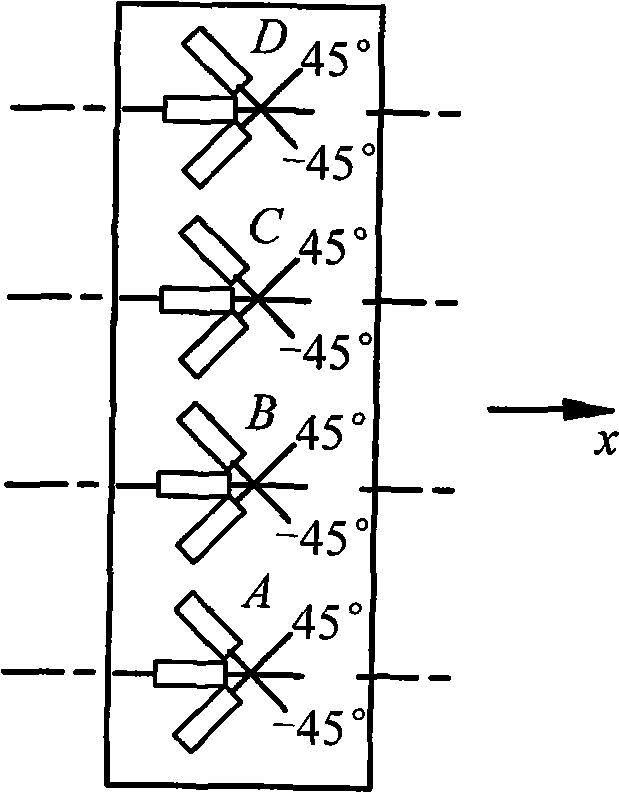

[0038] see figure 1 , figure 2 and Figure 6 In this embodiment, according to the rosette arrangement in the prior art, the rosette at point A is rotated 180° and pasted. As shown in the figure, the same as the prior art, the aluminum alloy cylinder cantilever bellcrank structure is adopted, which is composed of an aluminum alloy cylinder cantilever 1 and a bellcrank 2 at an angle of 90° to it. On the outer circumference of the cross-section, arrange four 45°-3 right-angle rosettes in the order of rosette A, rosette B, rosette C, and rosette D at intervals of 90°. The difference from the prior art is that in the axial direction of the cylindrical cantilever 1, the rosette B, the rosette C and the rosette D have the same orientation, and the rosette A is opposite to the other three rosettes, and the measuring point The position of the circle is the center of symmetry.

[0039] The application of the bending-torsion combined test device in this embodiment on the measurement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com