Liquid crystal display module group

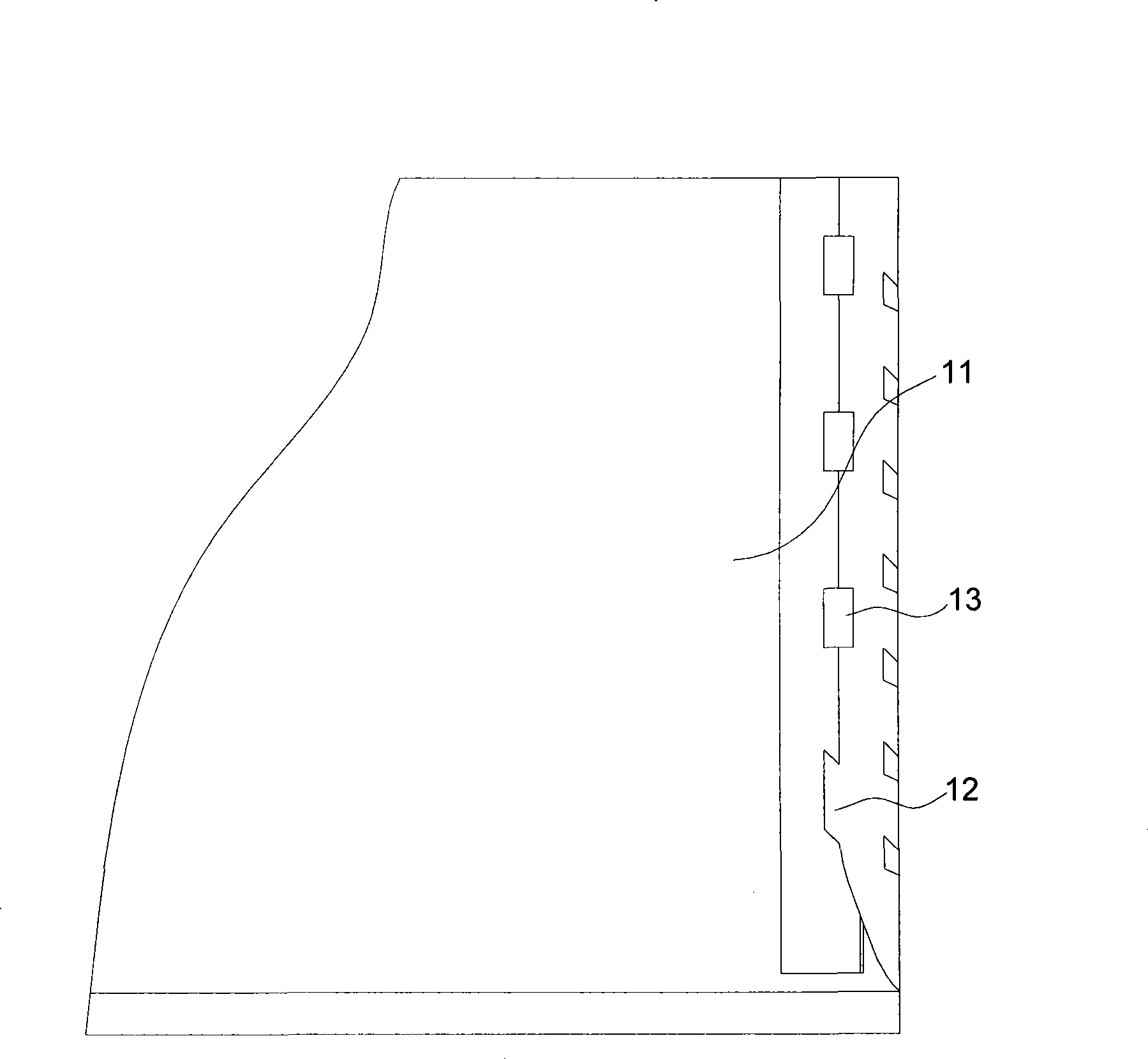

A technology of liquid crystal display modules and liquid crystal panels, applied in the direction of nonlinear optics, instruments, optics, etc., which can solve the problems of easy upturning and outward turning, the inability to fix the flexible circuit board 12 on the plastic frame 11, increase of manufacturing time and cost, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

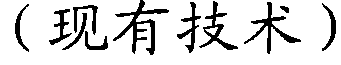

[0014] Figure 2A A liquid crystal display module 20 (unassembled) according to an embodiment of the present invention is shown. Those skilled in the art should know that the liquid crystal display module 20 can be used in, but not limited to, electronic devices, such as mobile phones, digital cameras, personal assistants (PDAs), notebook computers, desktop computers, televisions, car displays , an aviation display, a digital photo frame, a global positioning system (GPS) or a portable DVD player, etc.; preferably, the liquid crystal display module 20 is set in a mobile phone (not shown). It is worth mentioning that the schematic diagrams in this specification are for explaining the present invention, and the proportions and dimensions in the schematic diagrams as well as the relative positions of the components are for reference only and should not be used to limit the present invention.

[0015] The liquid crystal display module 20 includes a frame 40 , a liquid crystal pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com