Method and arrangement in web control at a junction point of the sub-totalities of a web-forming machine

A joint position, control device technology, used in paper machine, paper machine wet end, textile and paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

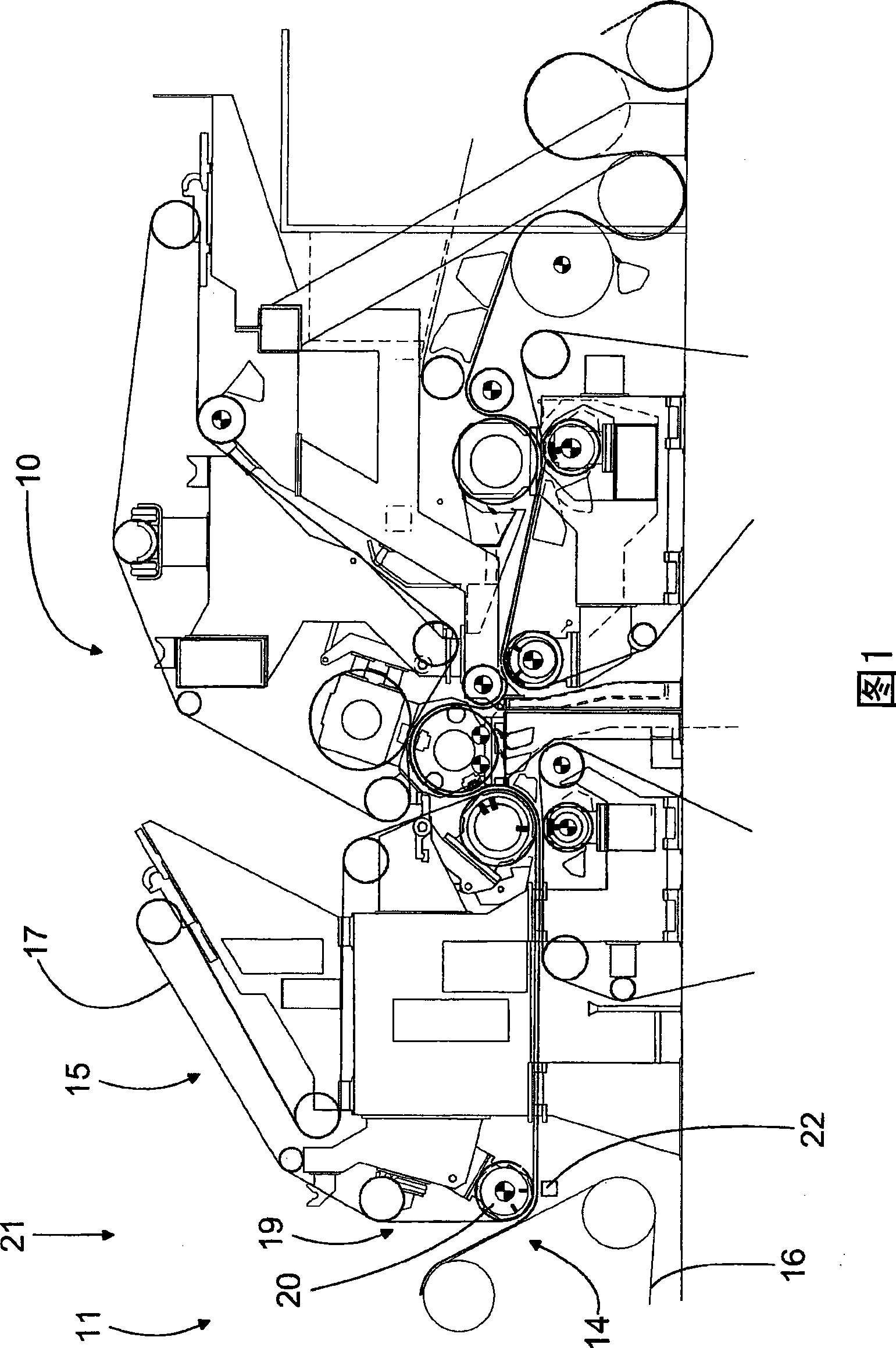

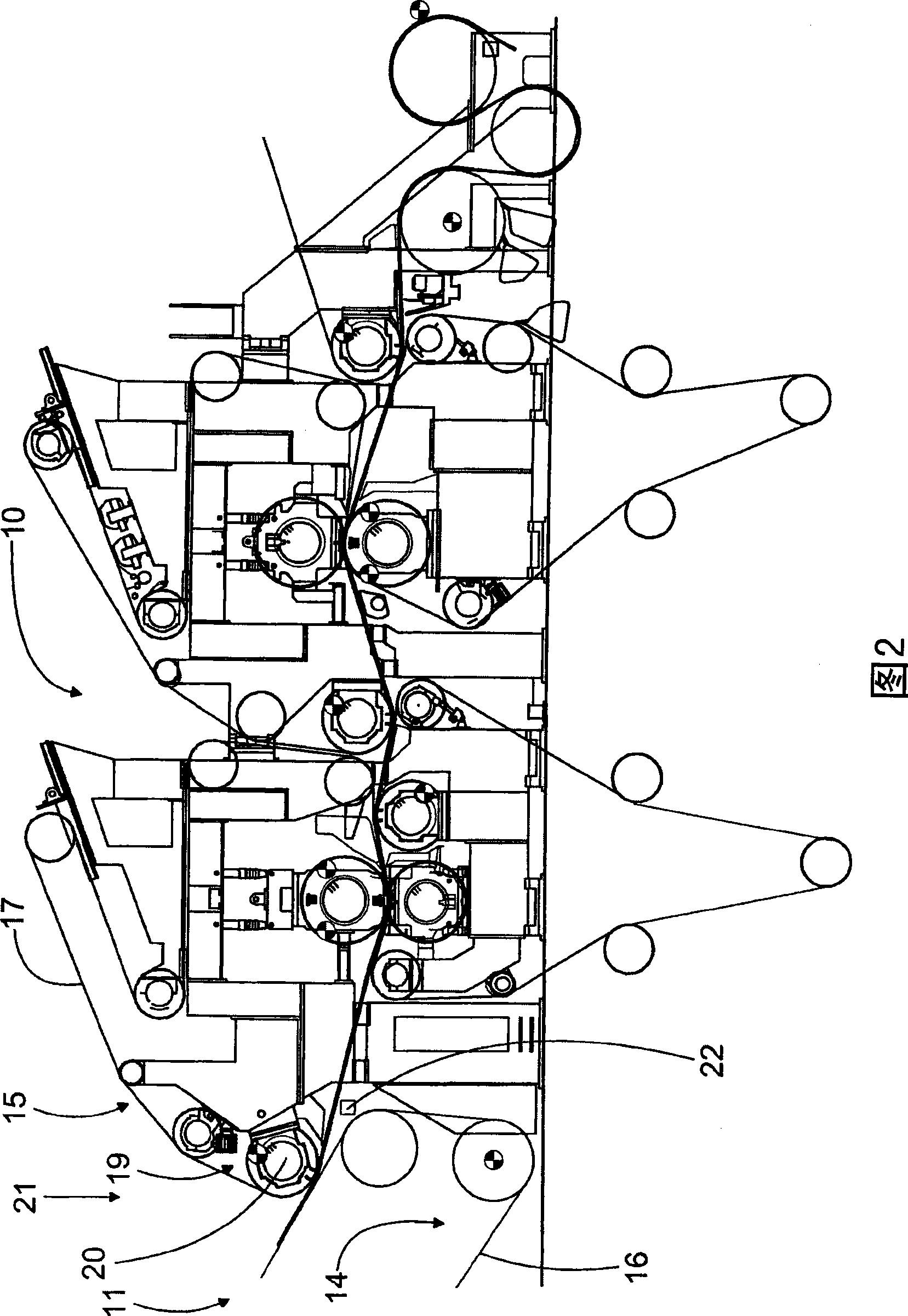

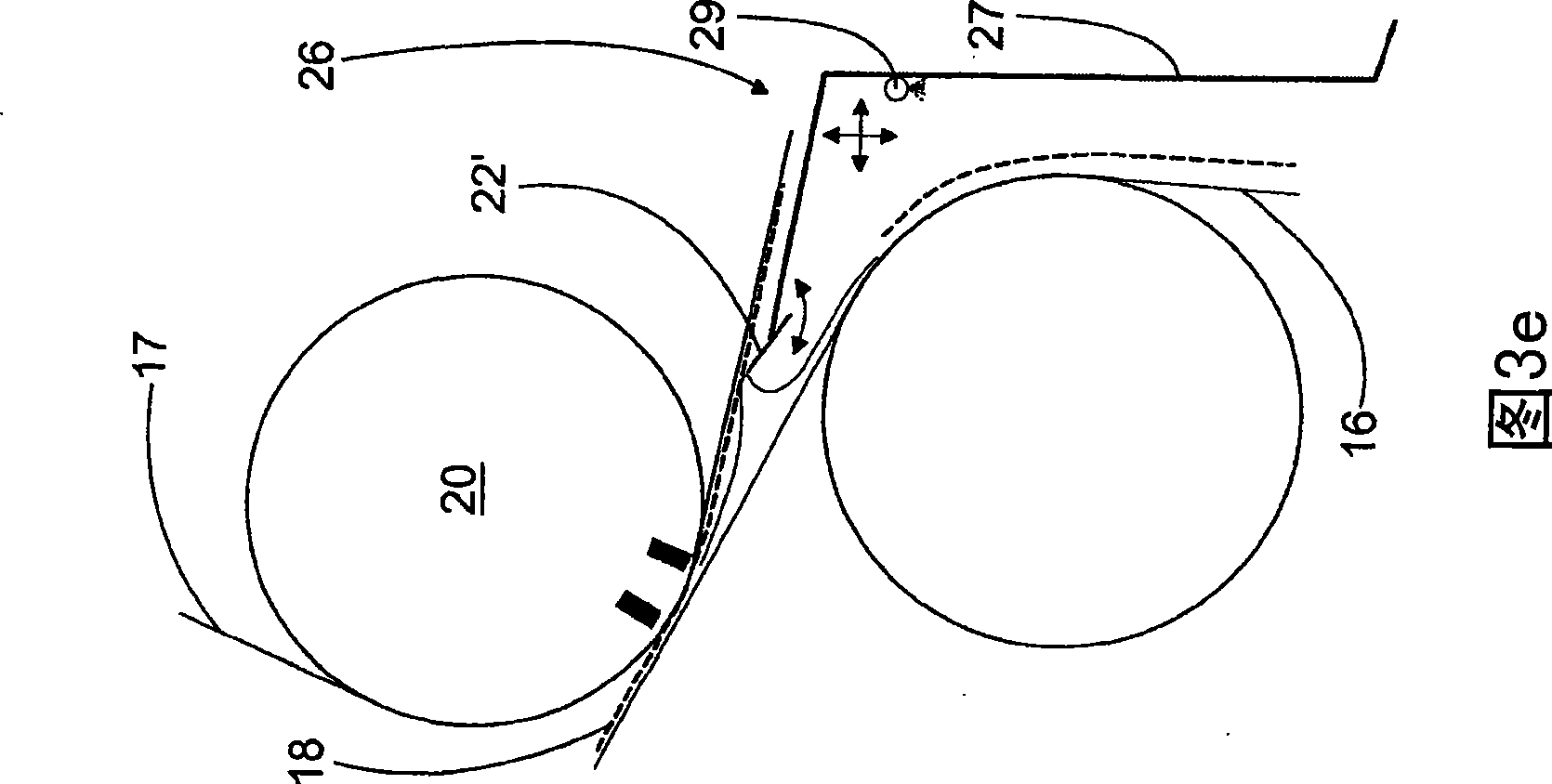

[0020] Figures 1, 2, 5 and 6 show four press sections 10, which, as well as a part of the web forming section 11 preceding the press sections 10, are well known. FIG. 5 additionally shows a horizontal impingement-drying unit 13 after the press section 10 , which is the initial part of the drying section 12 . Correspondingly, FIG. 6 shows the impingement dryer 34 following the press section 10 and the vertical impingement drying unit 13 which is the initial part of the drying section 12 . All four press sections are sub-assemblies of four large web forming machines, which may be paper or board machines. Typically, the web forming section includes at least one forming fabric that supports the web under manufacture and conveys the web forward. Correspondingly, the press section comprises at least one press fabric which likewise supports the web and conveys it onwards. The web forming machine is purposefully divided into several subassemblies which, in addition to the forming an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com