Film expansion mechanism of coating machine

A technology of film covering machine and film expansion, which is applied in the field of film film expansion mechanism of film covering machine, pasting and sealing, and labeling of bottled containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

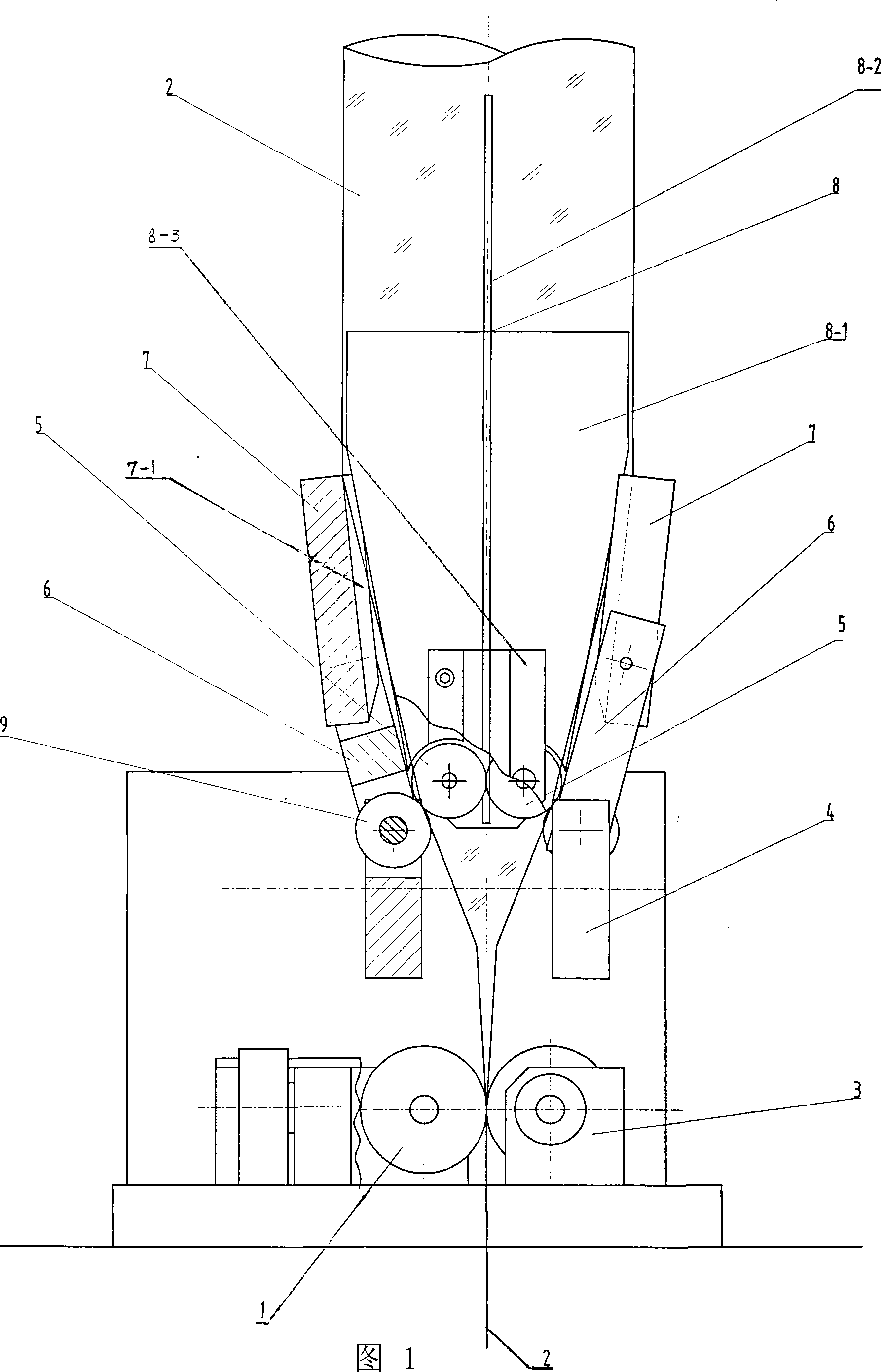

[0006] The present invention will be further described below in conjunction with accompanying drawing:

[0007] See attached drawing 1, the film expansion mechanism of the film covering machine is fixed in the middle of the film covering machine through the support (3), and is divided into two active and passive film feeding wheels (1) which are arranged in parallel on the plane of the support (3). The guide wheel support (4) is fixed on the vertical plane of the upper end of the support (3), and the symmetrically adjustable guide wheel support (4) is provided with a guide outer wheel (9), and the guide wheel support (4) upper end guides the outer wheel (9). ) shaft is connected with an inner wheel limit rod (6), and the upper end of the inner wheel limit rod (6) is connected upward with a guide floating rod (7), and the inner side of the guide float rod (7) is provided with a guide groove for the annular film (2) (7-1), the guider (8) is floating in the annular membrane (2), ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap