Flexion energy dissipation preventing support

A technology for preventing buckling, energy dissipation, and force-bearing components. It is applied in the directions of earthquake resistance and building components. It can solve problems such as difficult to spread evenly, damage support, and self-heavy weight, and achieve the effect of reducing the difficulty of production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

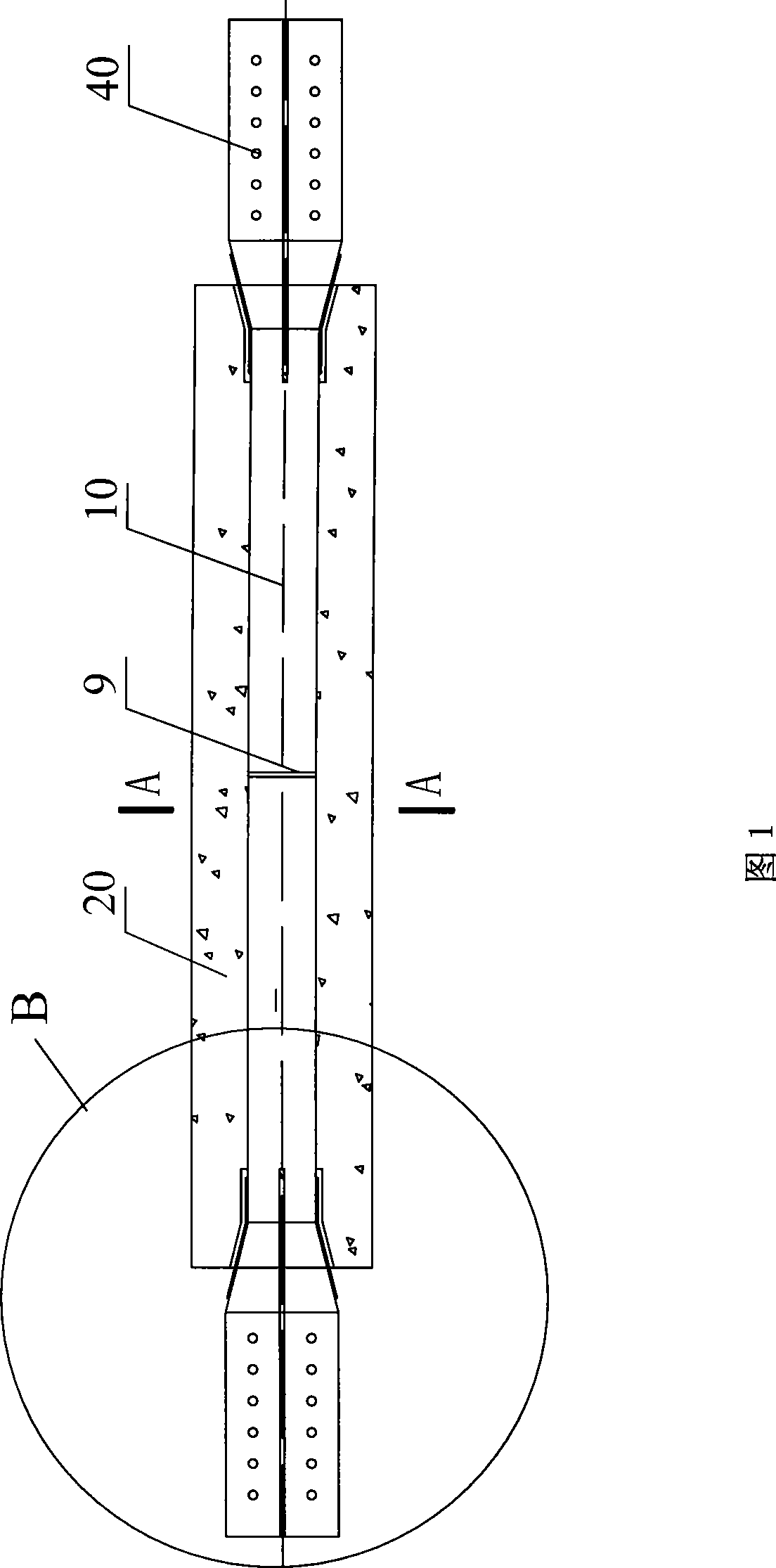

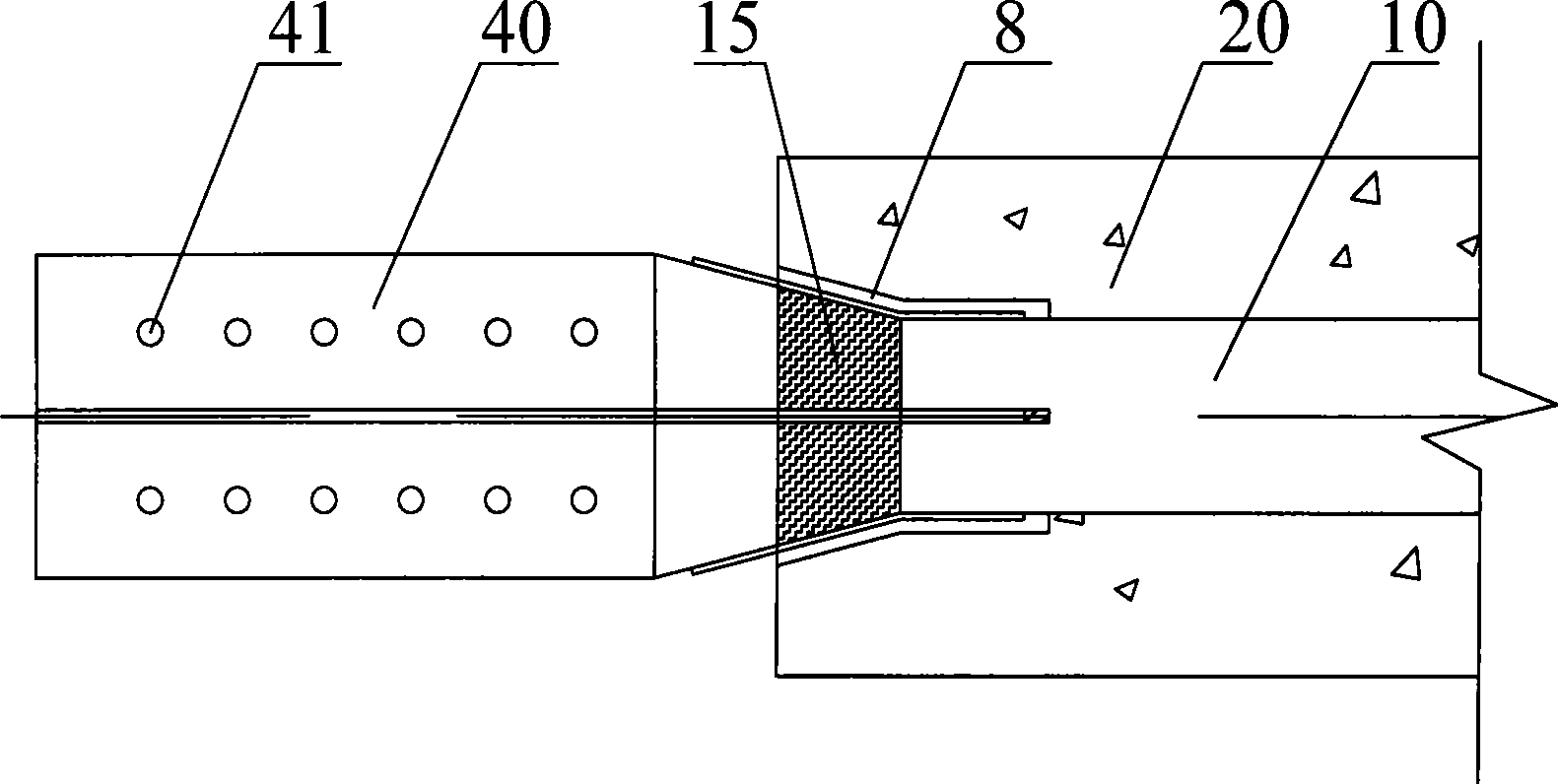

[0033] As shown in FIG. 1 , the anti-buckling energy-dissipating support of the present invention includes a core force-bearing member 10 , a constraint member 20 and a connecting member 40 . The two ends of the connecting member 40 and the core force-bearing member 10 can be fixedly connected by means of welding, etc., because the cross-section of the connecting part changes suddenly, there is stress concentration, and it is easy to be damaged, so a stiffened plate 8 (such as figure 2 shown) to increase strength. The connecting member 40 is provided with a bolt hole 41 so as to be connected with other structures by bolts. The constraining member 20 is sleeved on the outside of the core force-bearing member 10 .

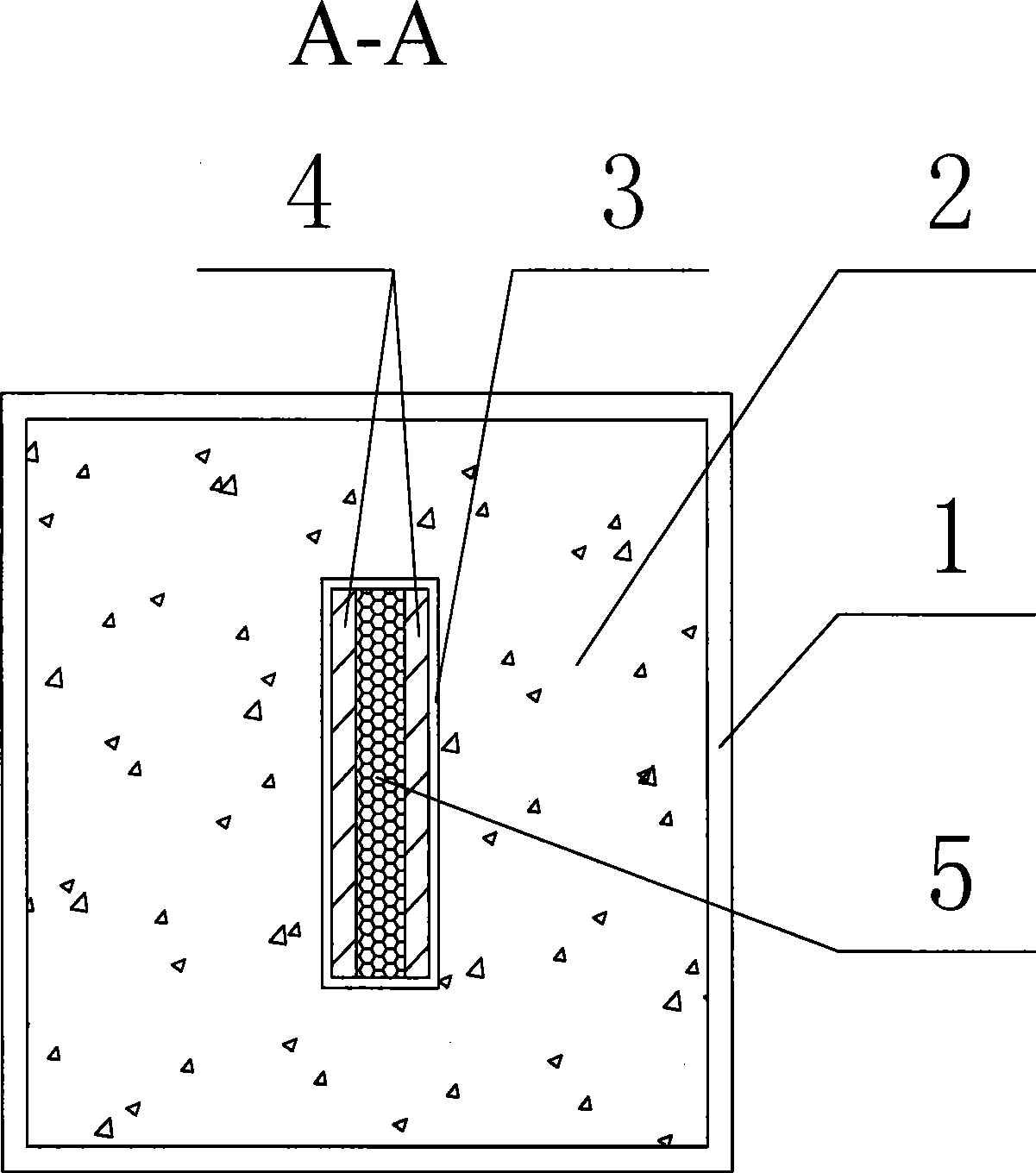

[0034] Such as image 3 As shown, the outer surface of the core force-bearing member 10 is provided with an anti-skid structure 9, and this anti-skid structure may be a semicircular protrusion or a pin or the like. When vibrating, the anti-slip structure 9 can pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com