Engine

A technology of engines and fuel injectors, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of insufficient time for complete evaporation of fuel, easy generation of carbon deposits, and reduced service life of parts, so as to simplify the structure and electronic control design , small temperature changes, and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

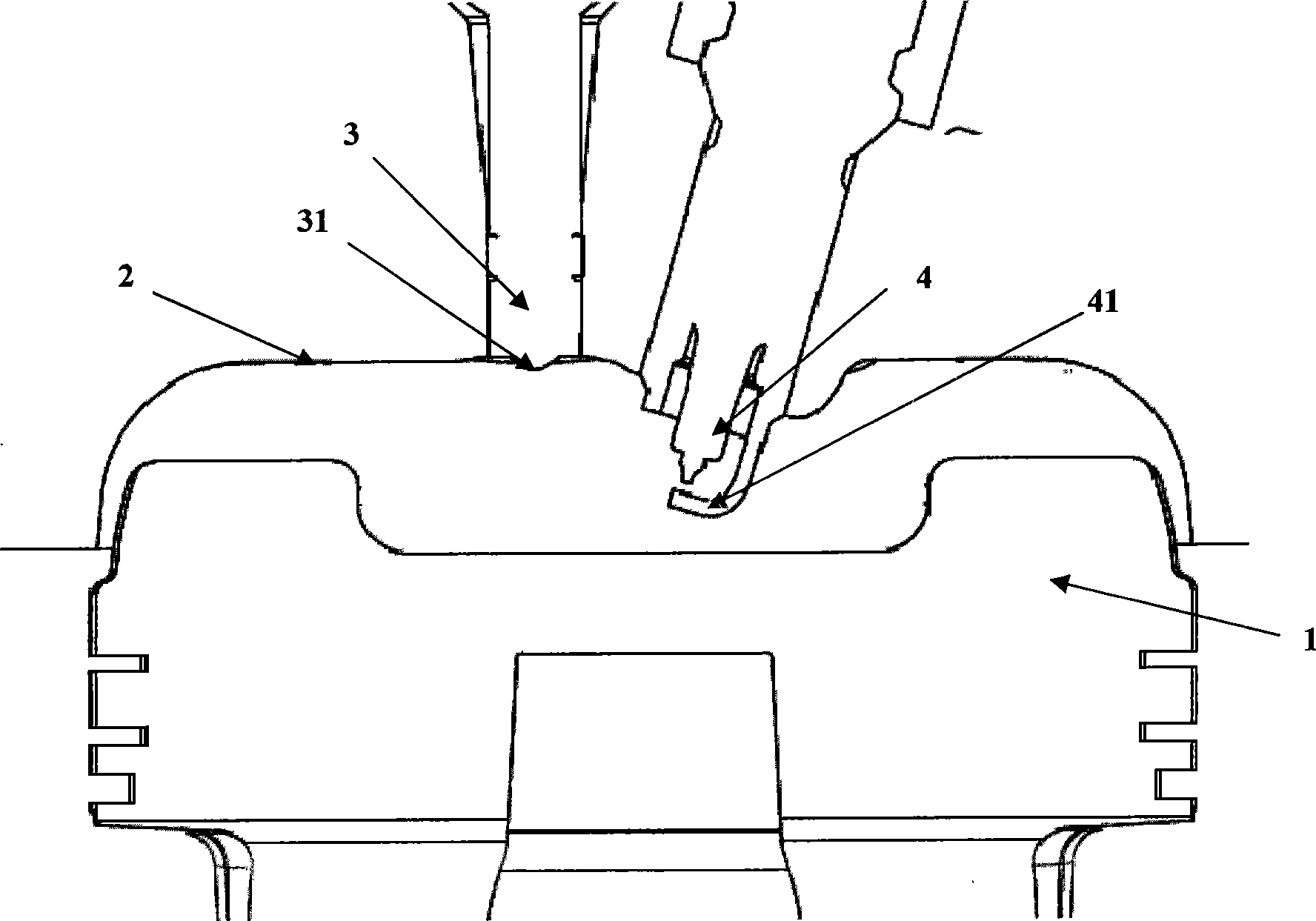

[0018] Such as figure 1 As shown, the engine of this embodiment includes a piston 1, a cylinder, a fuel injector 3 and a spark plug 4, and particularly a fuel injector 3 is arranged in each cylinder of the engine, and the fuel injector 3 is vertically arranged on the cylinder head 2, the spark plug 4 is close to and obliquely near the fuel injector 31 of the fuel injector, and the side electrode 41 of the spark plug 4 faces away from the fuel injector 31 of the fuel injector 3.

[0019] In order to ensure the installation angle and firmness of the spark plug 4, the spark plug 4 is fixed to the cylinder head 2 by threads, and the surface of the spark plug 4 and the screw hole of the cylinder head 2 are provided with installation positioning marks. The outer sealing washer of the spark plug 4 adopts a copper plane washer, and the upper part of the fuel injector 3 is pressed and fixed on the cylinder head 2 by a high-pressure fuel rail, and the fuel injector of the fuel injector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com