Trailer safety checking system

A safety inspection and trailer technology, which is applied in the field of safety inspection systems for trailers, and achieves the effect of extensive economical operation and wide adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

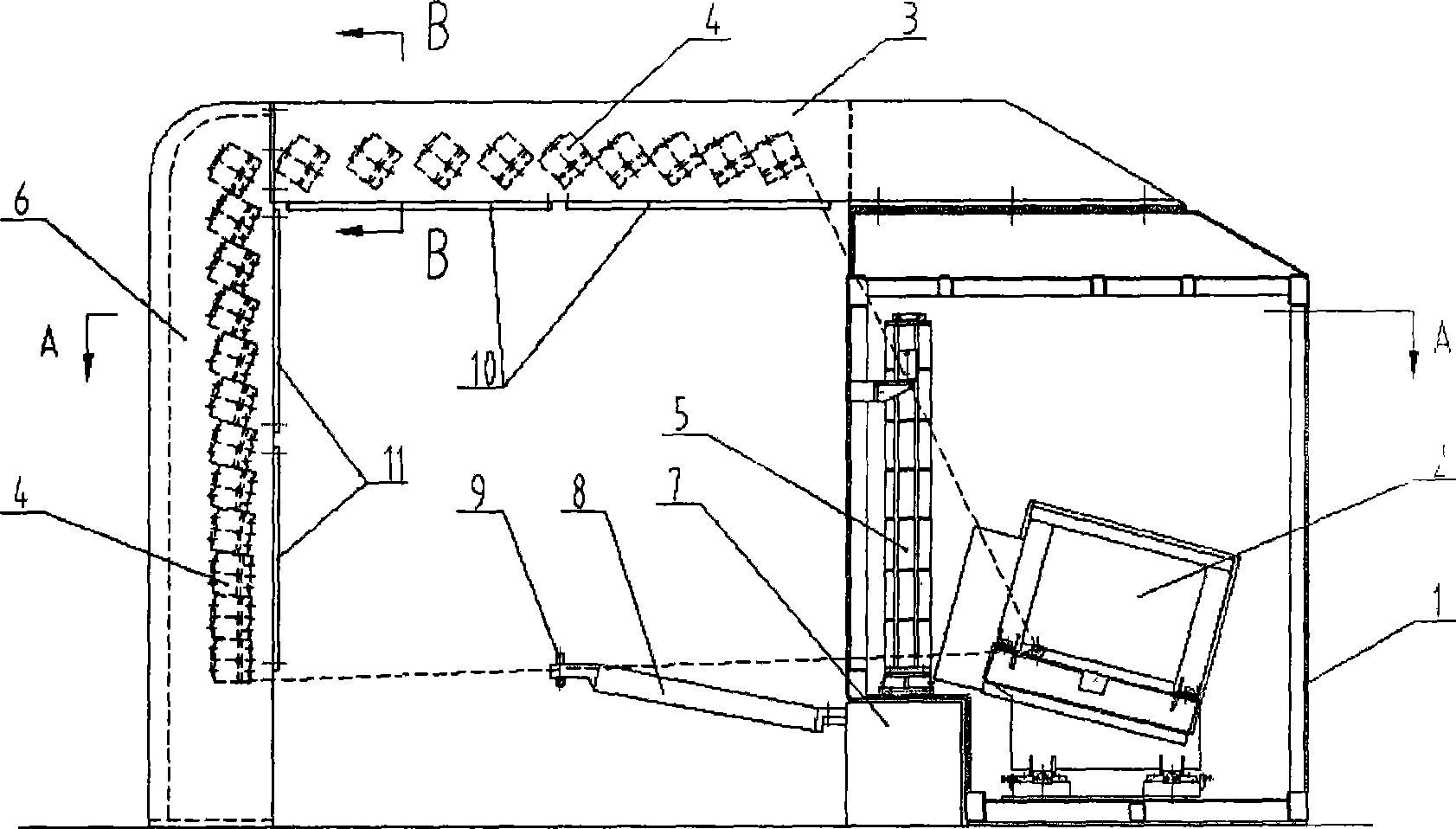

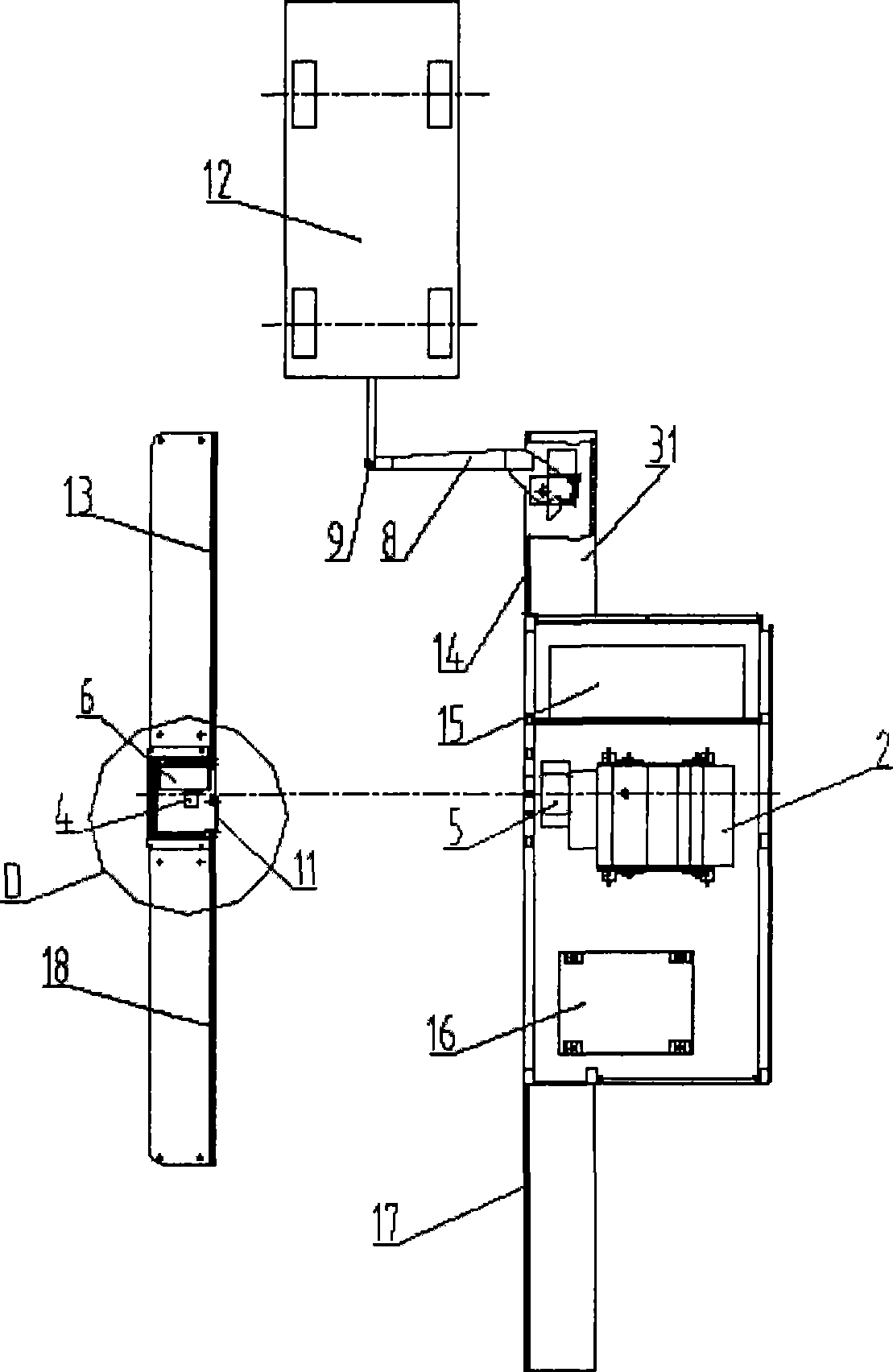

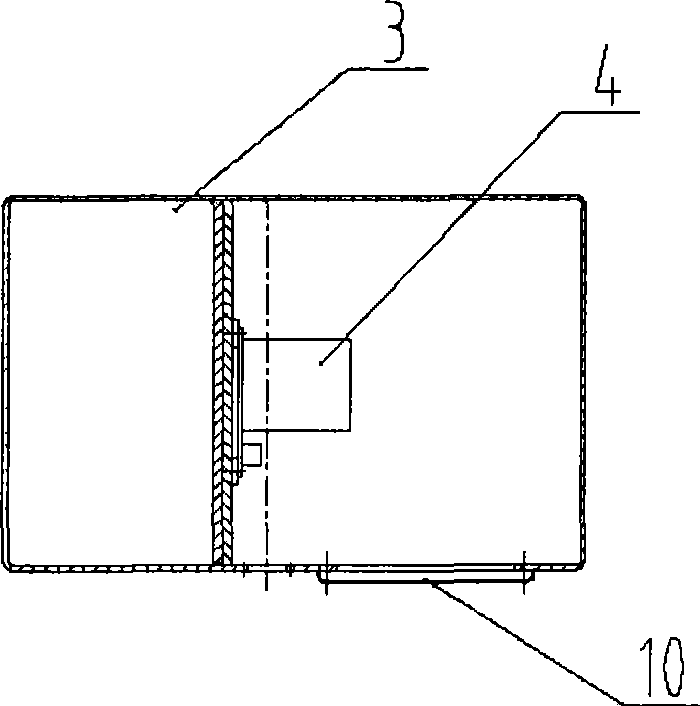

[0030] Such as Figure 1 to Figure 4 As shown, the trailer safety inspection system of the present invention includes an accelerator cabin 1 for installing a radiation imaging system, a protective wall forming a detection channel, a horizontal detector arm 3, a vertical detector arm 6, and a traction device for towing a trailer.

[0031] The protective wall includes four sections: protective wall I 13, protective wall II 18, protective wall III 14 and protective wall IV 17. The protective wall I13 and the protective wall II18 are respectively connected with the vertical detector arm 6, the protective wall III 14 and the protective wall III 17 are respectively connected on both sides of the accelerator cabin 1, and the protective wall is connected with the accelerator cabin 1 and the vertical detector arm 6. The connection method omits...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com