Directional control drilling system

一种方向控制、维修系统的技术,应用在定向钻井、钻井设备、土方钻采等方向,能够解决增加弯曲度、增加总时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

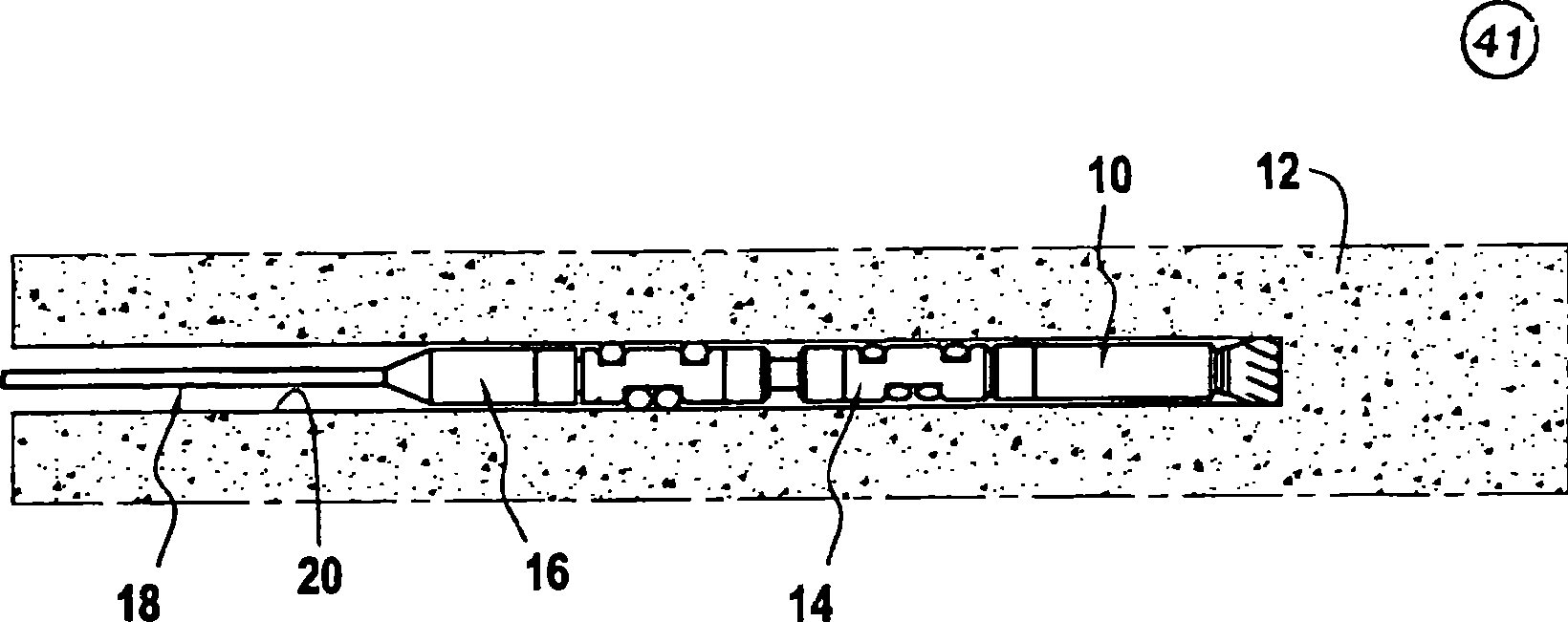

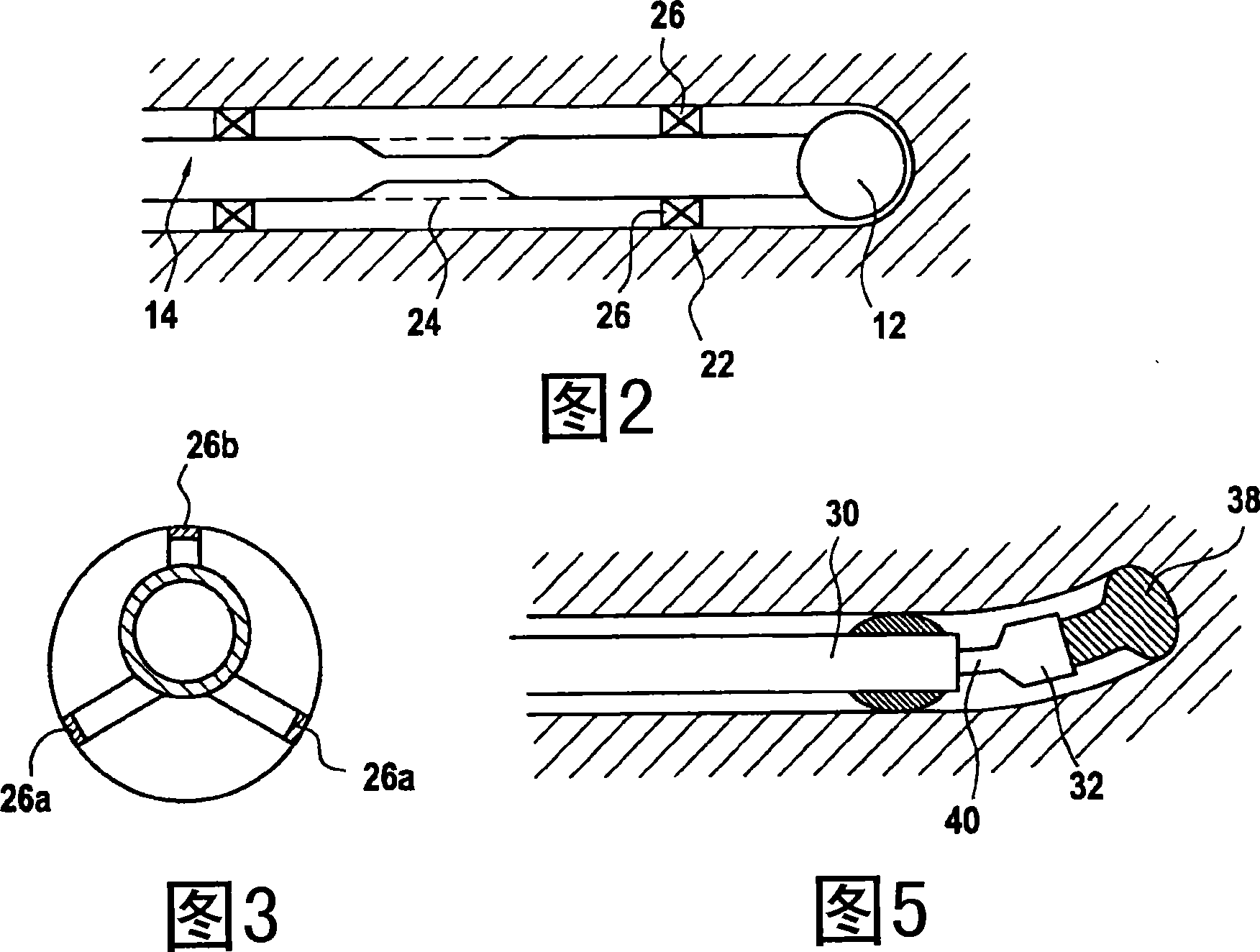

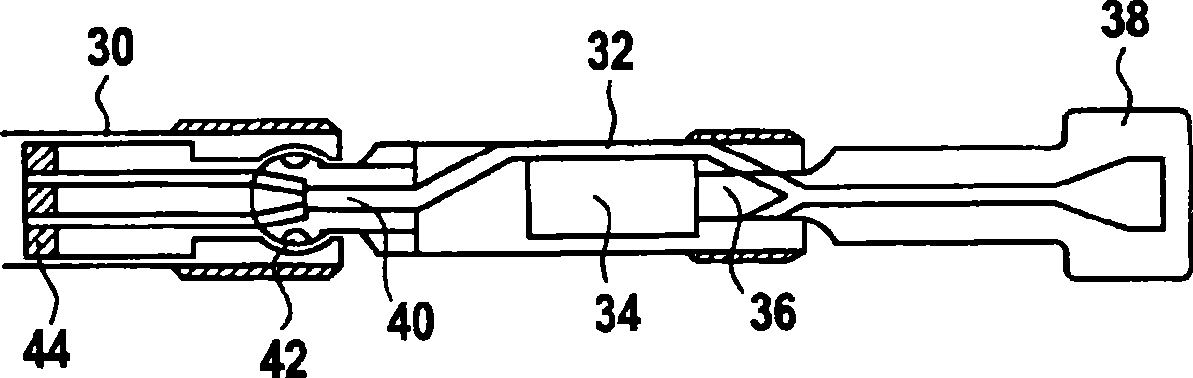

[0051] figure 1 A generally representative drilling system according to a preferred embodiment of the present invention is shown. The system includes a downhole drilling unit comprising a rotary drive system 10 carrying a drill bit 12 . A tool 14 comprising an axial drive system is positioned behind the rotary drive system 10 and is connected to the ground via a control 16 and a non-rotating conveyance 18 such as a cable or a flexible pipe with cables.

[0052] Rotary drive system 10 includes an electric motor by which drill bit 12 is turned. The power of the motor depends on its size, although for many applications, the power of the motor will not exceed 3kW.

[0053]In use, the drilling system is advanced into the wellbore 20 until the drill bit 12 reaches the bottom. Drilling continues by rotating the drill bit 12 using the rotary drive system 10 and advancing the drill bit into the formation using the axial drive system in the tool 14 . The rotation and advancement of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com