Racket holding device of racket threading machine

A technology of clamping device and threading machine, which is applied in the direction of threading rackets, rackets, sports accessories, etc., can solve the problems of racket frame deformation, lower racket yield, affect racket line density, racket line tightness, etc., to achieve Effect of reducing deformation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

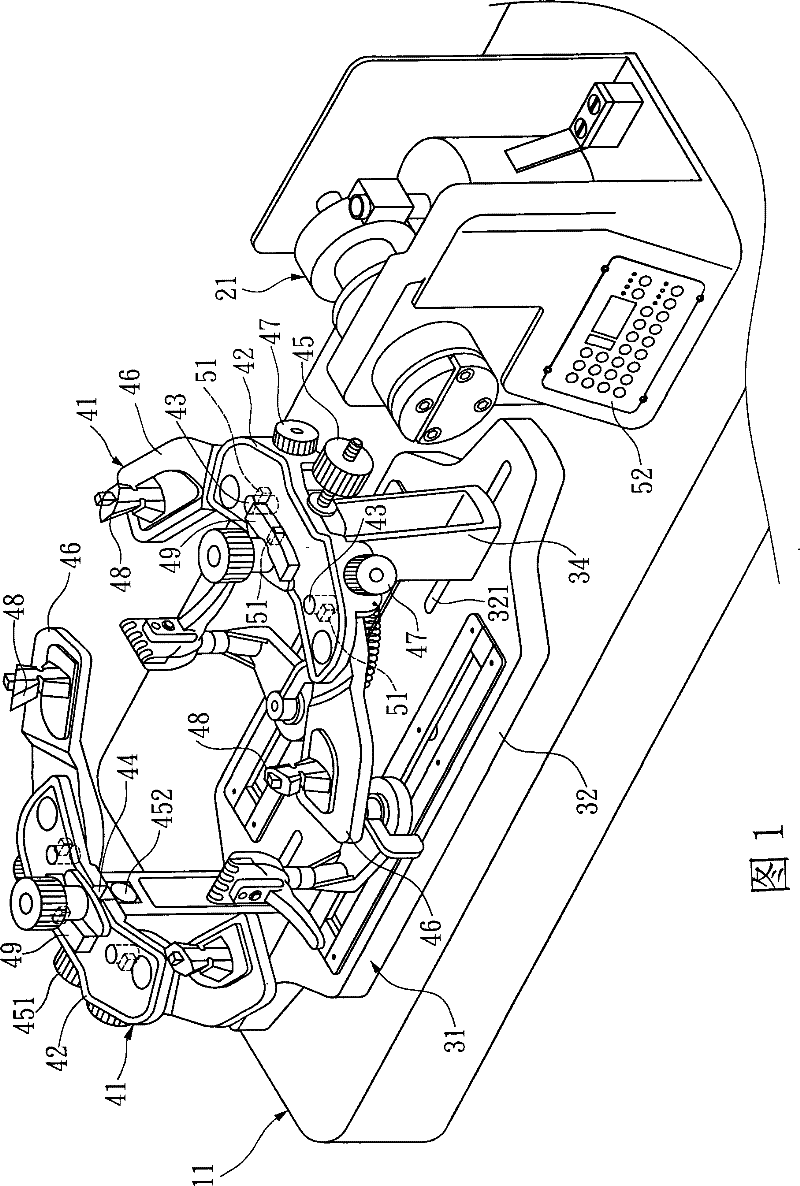

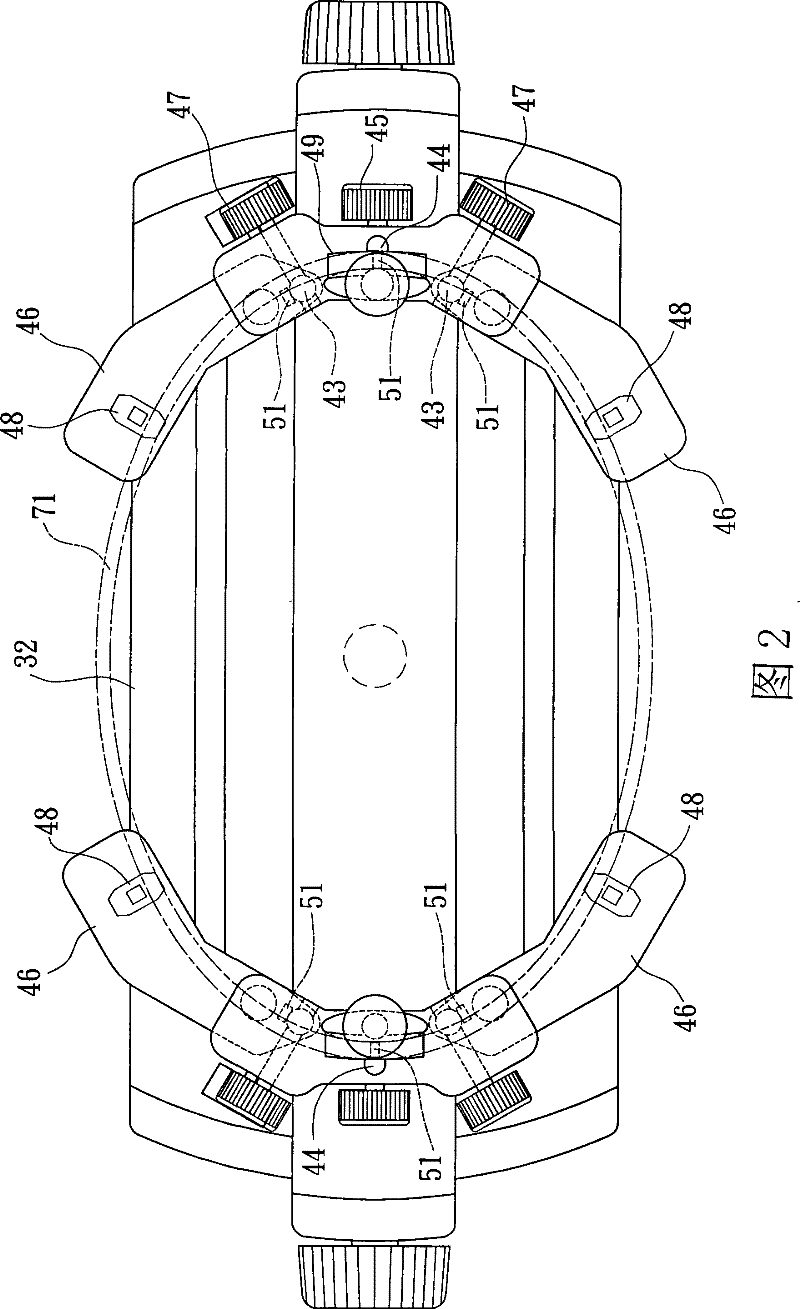

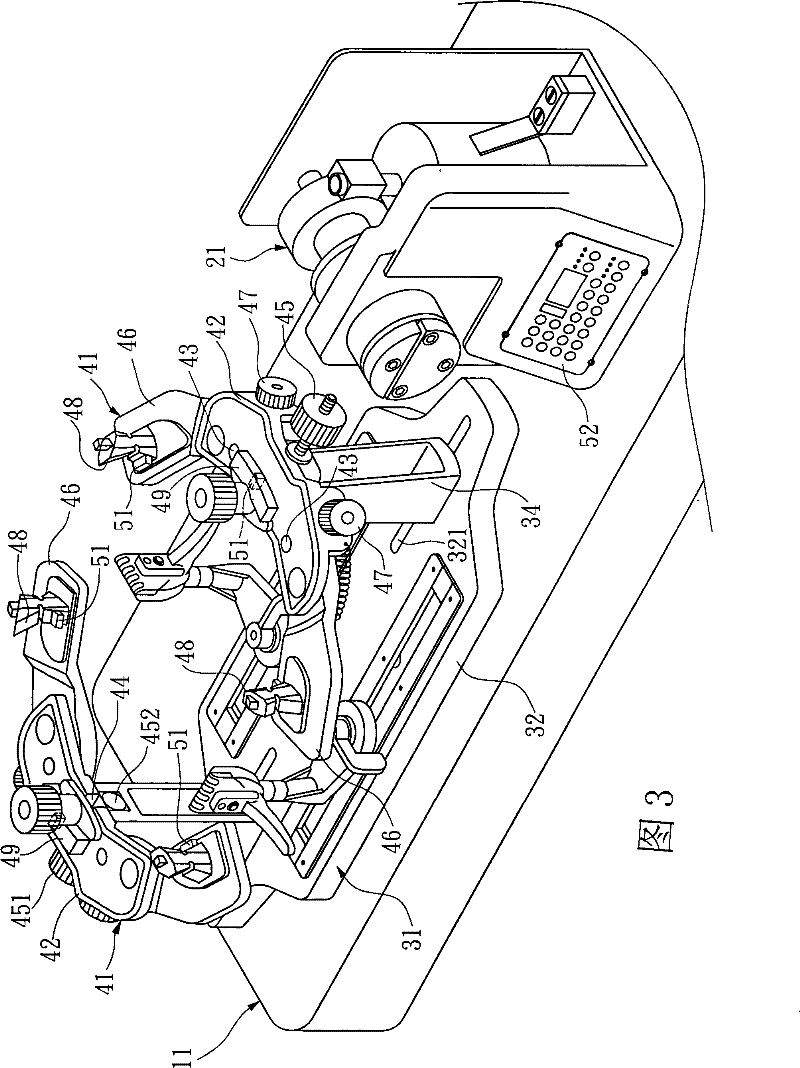

[0021] First please refer to figure 1 and figure 2 , the present invention relates to a racket clamping device for a racket stringing machine, the stringing machine includes a base 11, a wire pulling device 21 and a rotating table 31, one end of the base 11 is provided with a wire pulling device for controlling the tension of the racket string 21, the other end is a turntable 31 that can rotate horizontally; the turntable 31 includes a bottom plate 32, two movable frames 34 and two racket clamping devices 41, the bottom plate 32 is provided with a number of rail grooves 321, and the movable frame 34 is Located in the rail groove 321 , the movable frame 34 can move in the rail groove 321 and be fixed at a specific position of the bottom plate 32 , so that different distances between the two movable frames 34 can be used for rackets of different sizes.

[0022] The racket clamping device 41 is composed of a main body 42, two clamping arms 46, a hook 49, several sensors 51 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com