Sample traveling stage with flexure mechanism module to absorb the deformation of the slide

A technology for transporting platforms and flexible mechanisms, which is applied in the direction of sampling, optical devices, instruments, etc., which can solve the problems of sample table 116 deformation, increased usability level, and different deformation degrees, and achieves improved measurement accuracy and high control stability. Improvement of performance and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Examples of the present invention are explained below.

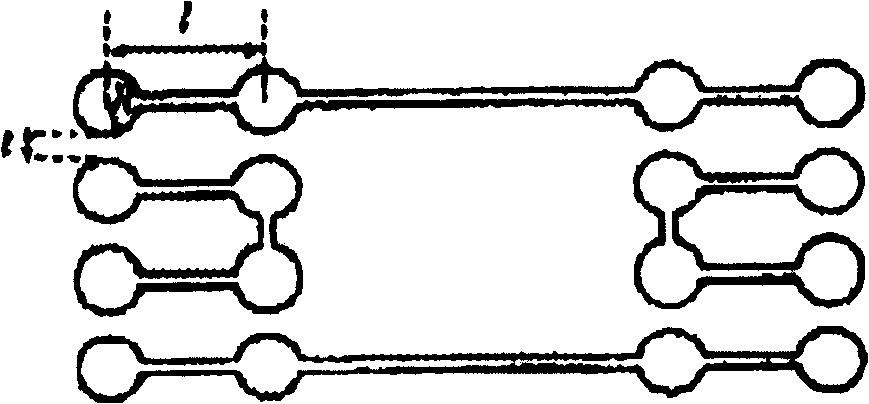

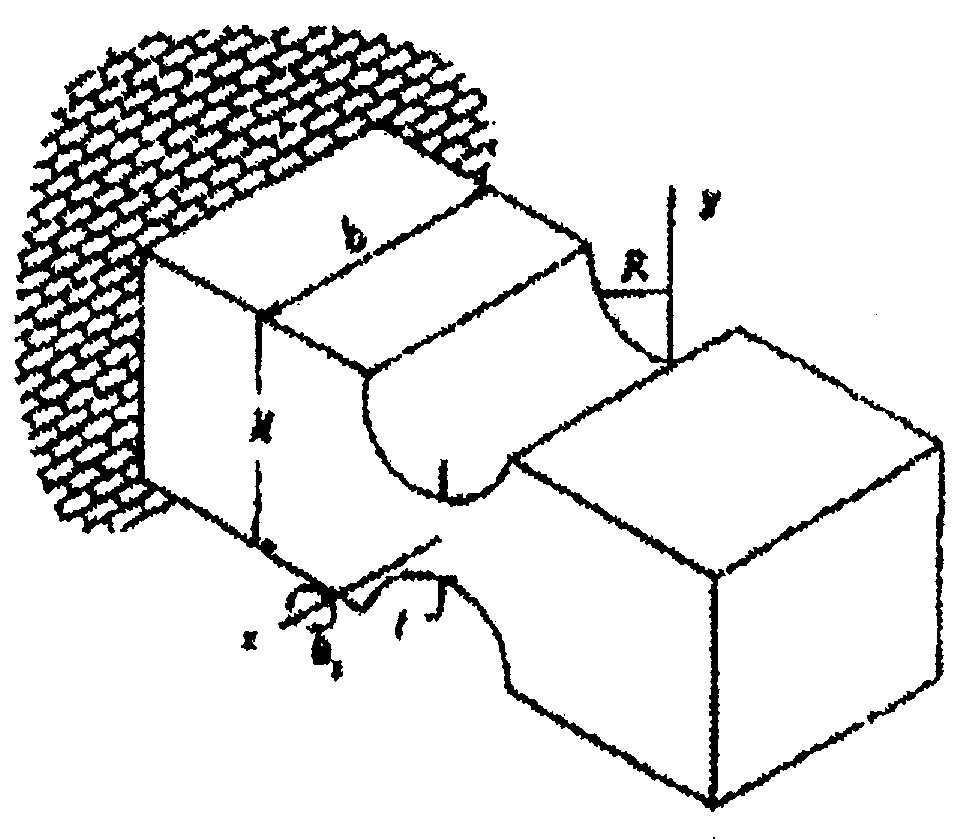

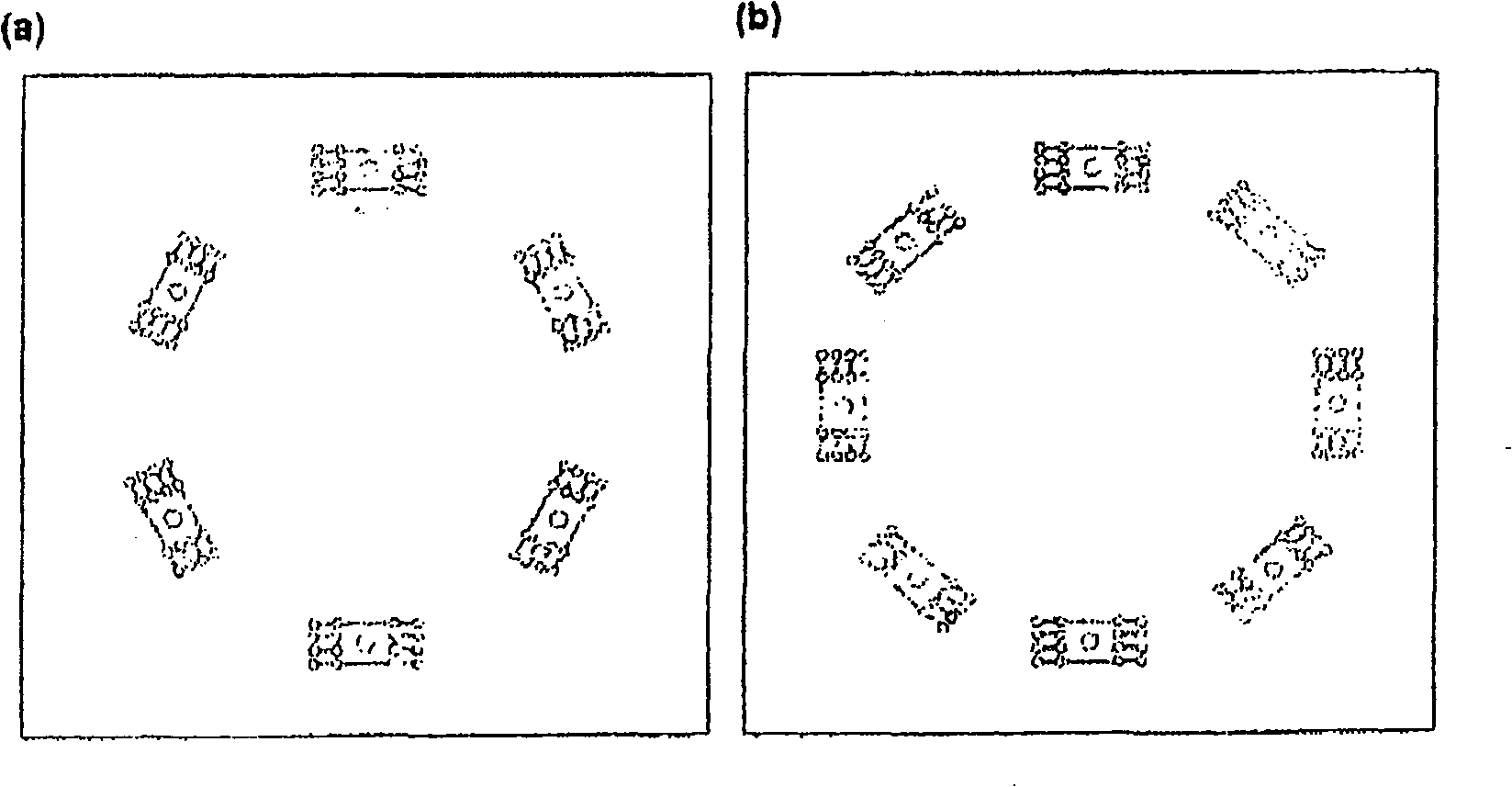

[0049] Figure 5 and Figure 6 shows the assembly and disassembly of the sample delivery platform; Figure 7 Shows the flexible mechanism module that is used for the sample delivery platform according to the present invention; Fig. 8 and Fig. 9 are example 1 and example 2, have shown the installation situation and deformation situation of flexible mechanism; And Figure 10 is an exploded view showing an example of a flexible mechanism module according to the present invention.

[0050] according to Figure 5 and Figure 10 , it consists of a moving part that is installed in a cross direction, thus installed on the base 10 and moving along the first guide block 21 first slide rail 20, and installed on the above-mentioned first slide rail 20 and moving along the second The second sliding rail 30 that the guide block 32 moves; the transporting part that transports the sample 41 through the sample stage 40 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com