Laser encapsulation structure and method

A technology of laser encapsulation and mask plate, which is applied in the direction of laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of affecting production efficiency, increasing load, and decreasing encapsulation accuracy, so as to simplify equipment complexity, reduce encapsulation error, The effect of improving packaging yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

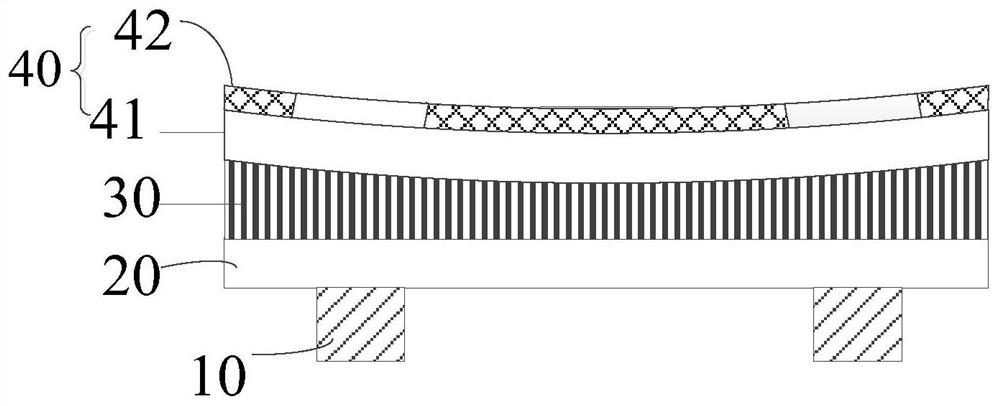

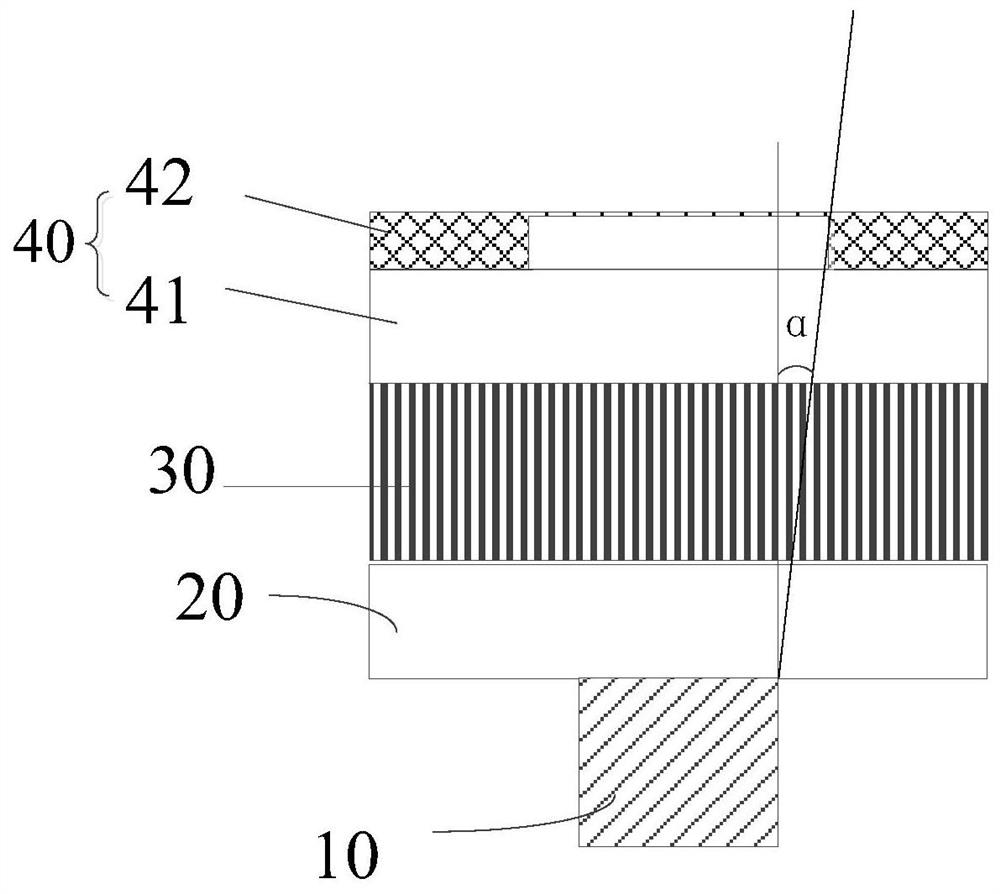

[0050] Please refer to Image 6 , the present invention provides a laser packaging method, comprising

[0051] Step 1: Please refer to image 3 , set the mask to 100, specifically:

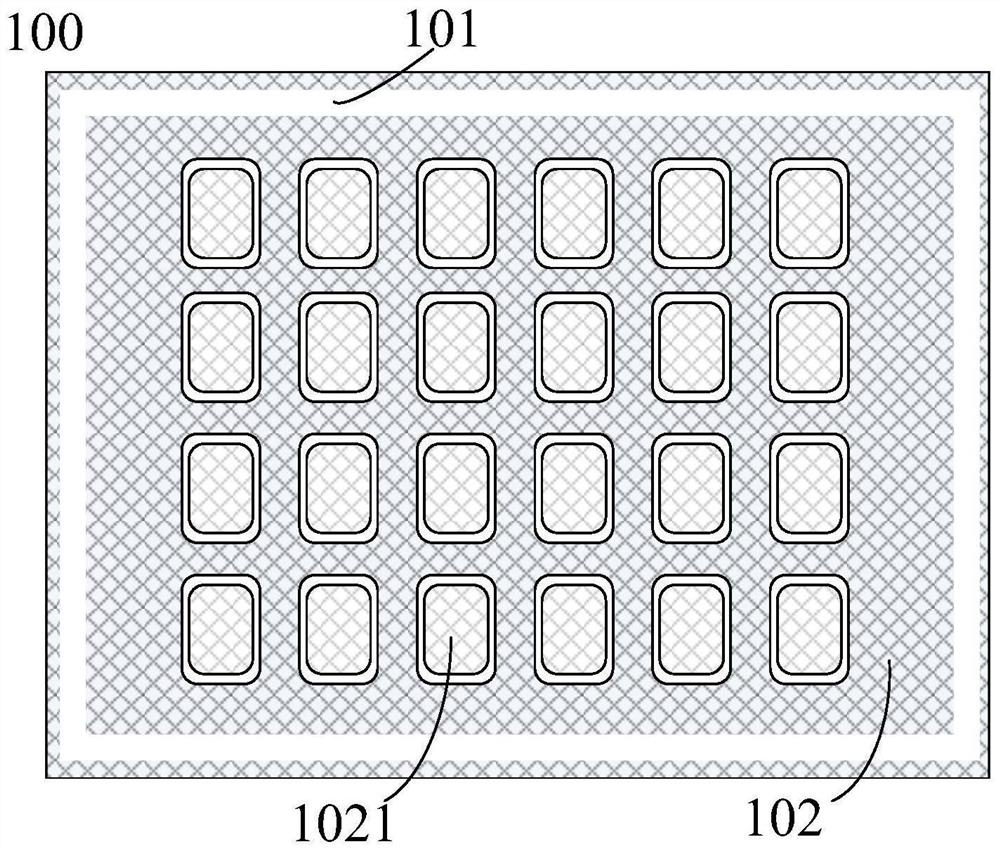

[0052] The mask 100 includes a glass substrate 104 and a chromium surface 102 sputtered on one side of the glass substrate 104. The chromium surface 102 forms a packaging pattern 1021. On the mask 100, a layer where the chromium surface 102 is located is provided with a glue-coated area 101. In this embodiment In the example, the glue-coated area 101 is a groove formed by the chromium surface 102 being recessed toward the glass substrate 104, but when preparing the mask 100, the glass substrate 104 is etched out of the groove before the chromium surface 102 is formed, and then chrome is sputtered. Form the chrome surface 102, the shape of the entire glue-coated area 101 is a ring or a rectangle, which surrounds the package pattern 1021, and the glue-coated area 101 bypasses the package pattern 1...

Embodiment 2

[0068] The difference between this embodiment and Embodiment 1 is that, if Figure 9 As shown, the glue-coated area 101 on the mask 100 is a concave point formed by the chrome surface 102 being recessed toward the glass substrate 104. The concave points are distributed at the four corners of the mask 100, and the four corners are connected in turn to form a rectangle. The rectangle encapsulates the pattern 1021 surrounds the center, and the organic glue 103 is coated in the concave point, and it is temporarily bonded with the package upper substrate 201 under vacuum negative pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com