Automatic Alignment and Positioning Method for Base Paper in Corrugated Board Production Line

A corrugated cardboard and automatic alignment technology, which is applied in the direction of winding strips, function indication, thin material processing, etc., can solve problems such as waste of batches, lack of corrugated cardboard materials, and a small amount of paper roll deviation, so as to save production costs, The effect of saving paper cost and saving base paper waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The base paper automatic alignment and positioning method of the corrugated cardboard production line described in the present invention is further explained by taking the seven-layer corrugated cardboard production line as an example; Figure 5 As shown, the seven-layer corrugated cardboard production line consists of No. 1 lining paper roll station 1, No. 2 corrugated paper roll station 2, No. 3 sandwich paper roll station 3, and No. 4 corrugated paper roll station 4, which are arranged at longitudinal intervals. , No. 5 sandwich paper roll station 5, No. 6 corrugated paper roll station 6, and No. 7 surface paper roll station 7. The paper rolls of each paper roll station are respectively placed on the web support.

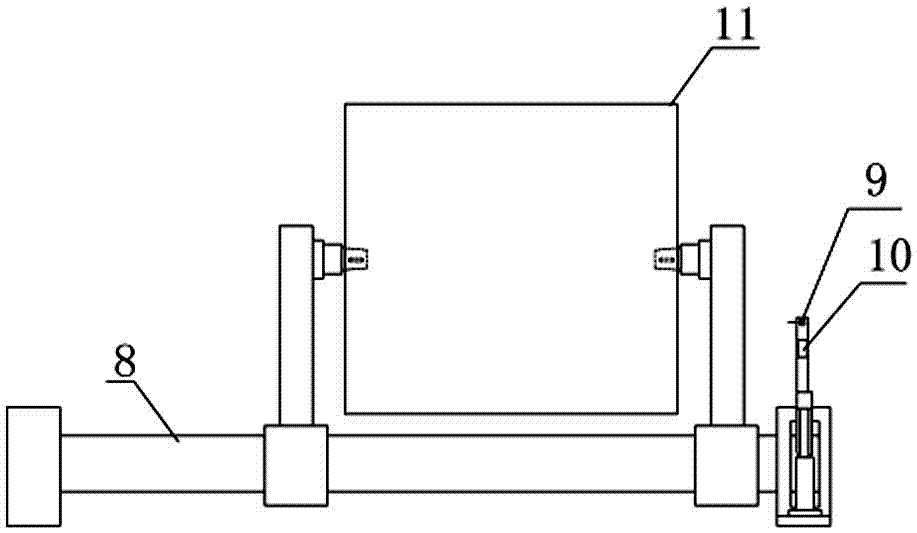

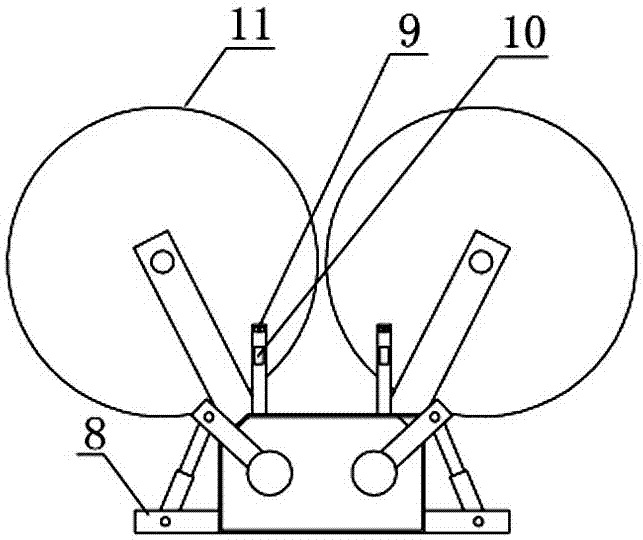

[0018] first step, such as Figure 2-4 As shown, macro-distance laser rangefinders 9 and wireless data transceivers 10 are respectively installed at the power ends of the web support 8 at each paper roll station of the seven-layer corrugated cardboard prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com