Electric wave darkroom capable of carrying out acoustic testing and building method thereof

An anechoic chamber and acoustic testing technology, used in chemical instruments and methods, building components, laboratory utensils, etc. The problem of high construction cost can avoid repeated construction and save construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples, but these examples should not be construed as limiting the present invention.

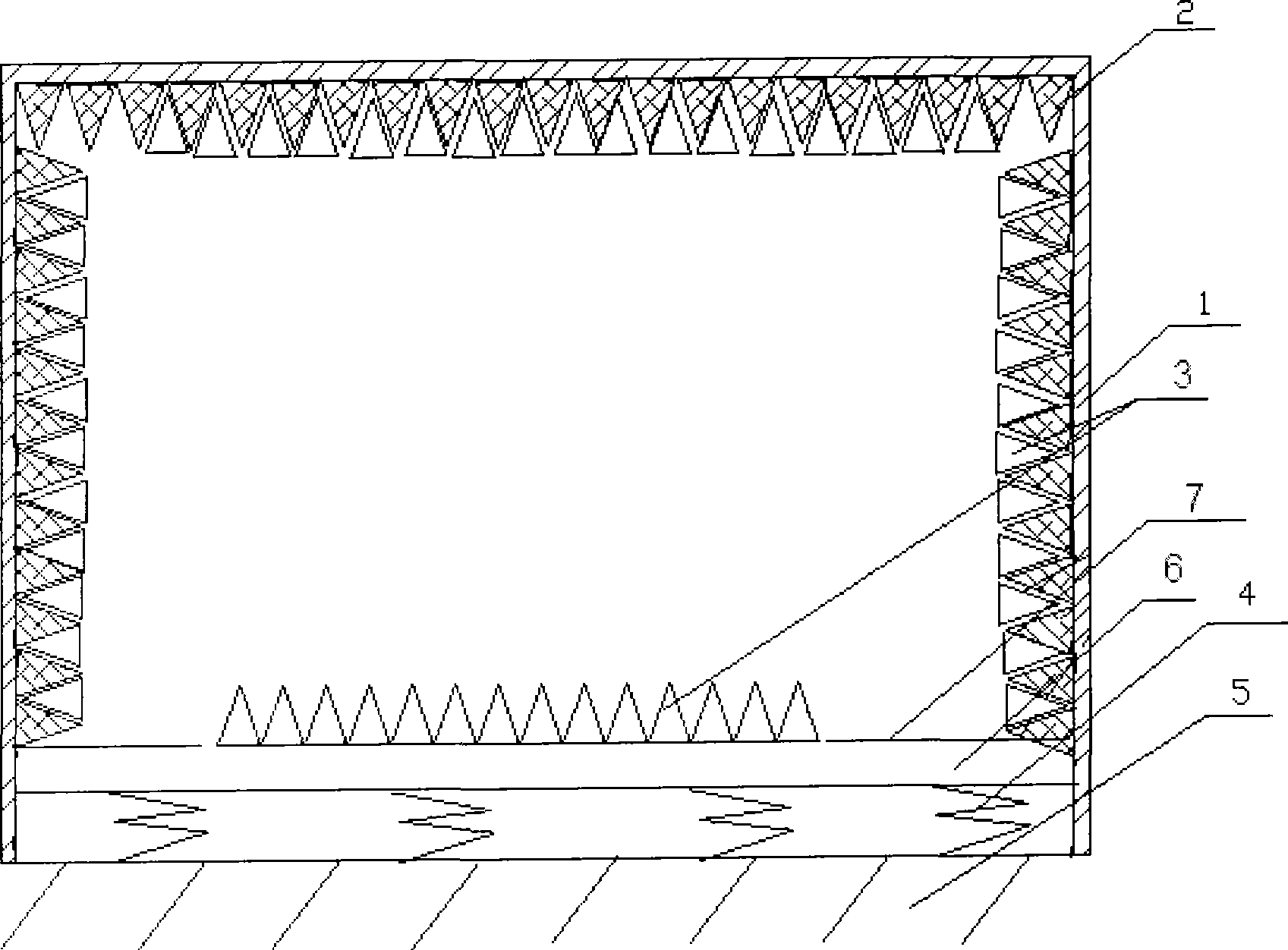

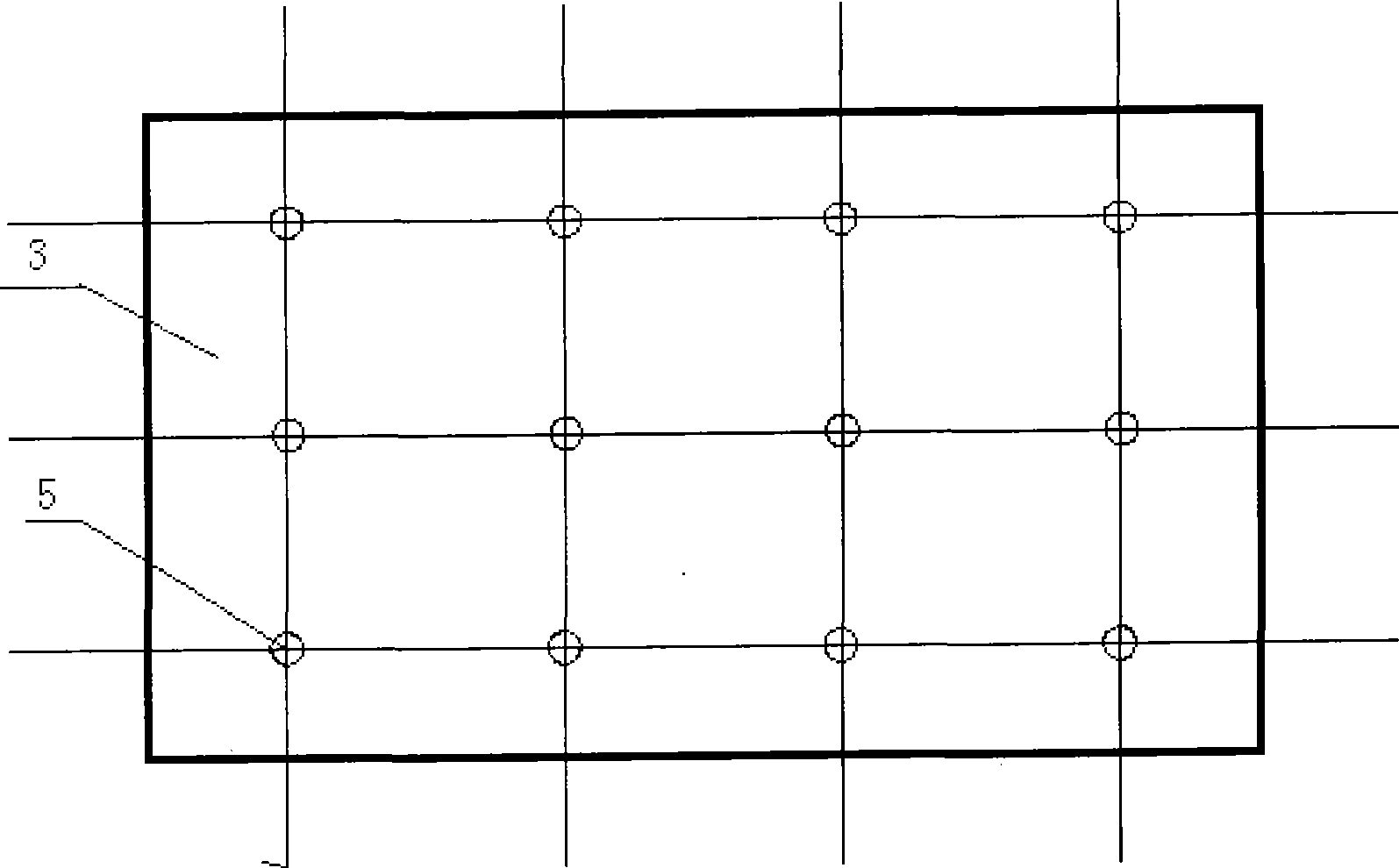

[0017] The present invention carries out the sound absorption design on the basis of a 10m anechoic chamber of 21m (L) * 14m (W) * 11m (H) (clear space).

[0018] The shielding body of this anechoic chamber adopts 3mm steel plate, and the absorbing material is a 2.4m wedge. Its specific steps are:

[0019] The first step: send the sample of the absorbing material to a professional acoustic testing organization for sound absorption performance testing: for the same material, the sound absorption increases with the increase of the frequency. , generally the most severe frequency point is used as the basis for assessment.

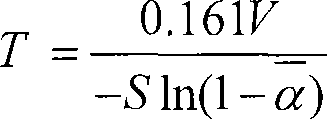

[0020] In this embodiment, the experimental assessment frequency is selected as 125Hz. The area of the absorbing material sample is 44.1m 2 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com