Double-sided opposite pressing interior trim molding hydraulic press

A technology for hydraulic presses and interiors, applied in the field of hydraulic machinery, can solve the problems of low-grade interior moldings, inability to adapt to high-end automobiles, and poor thickness uniformity, and achieves good density, reduced total weight, and thickness uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

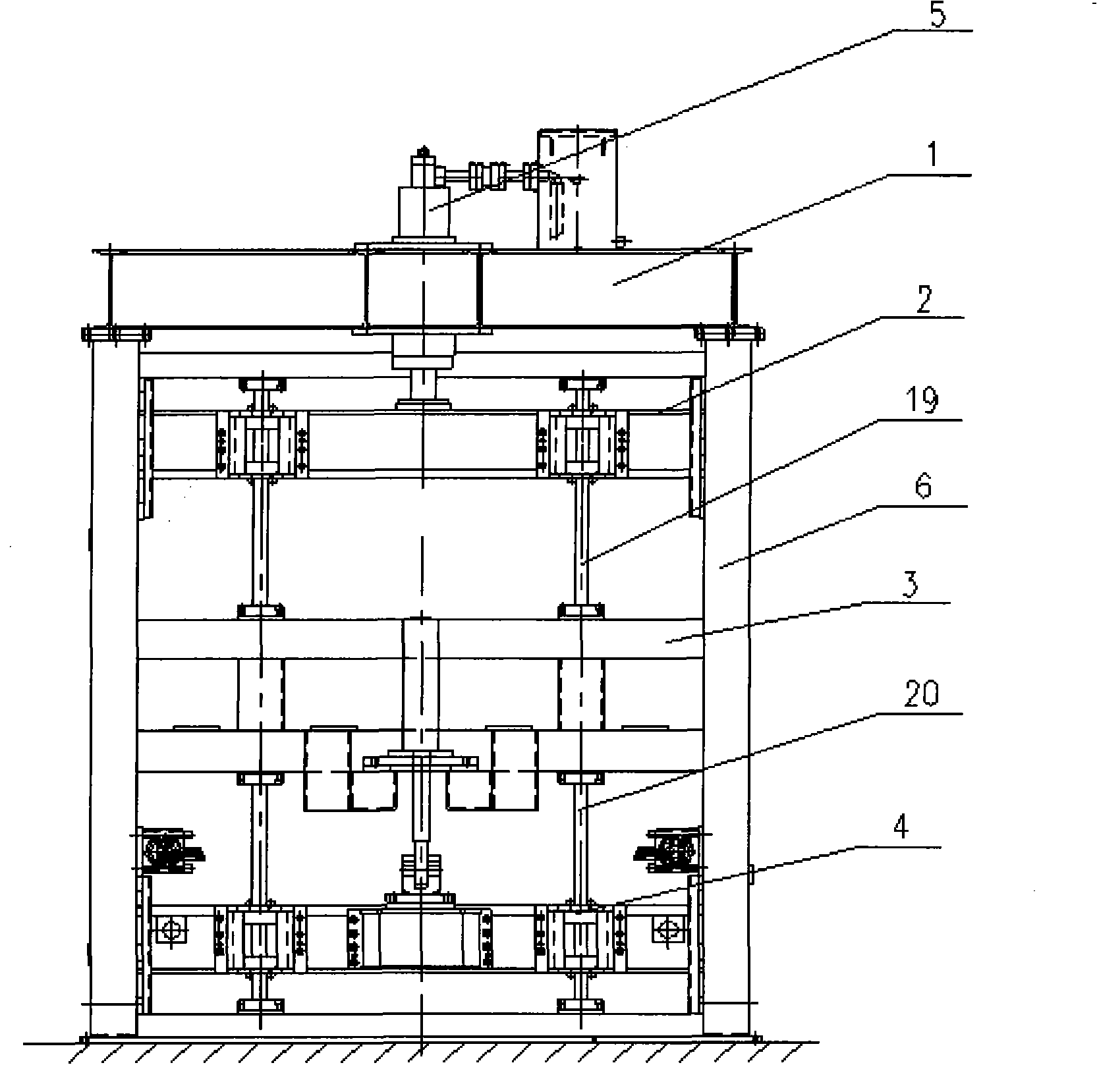

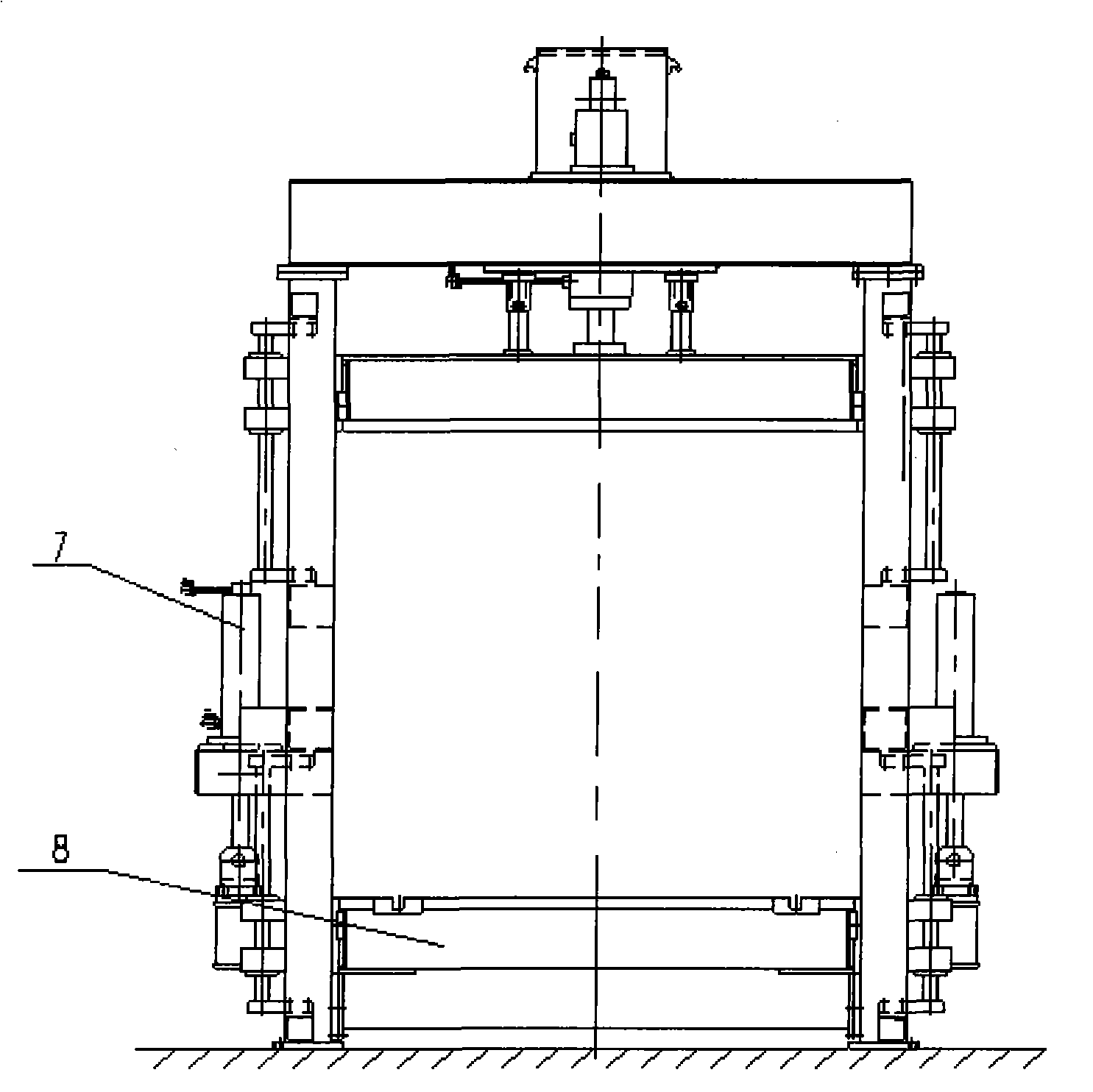

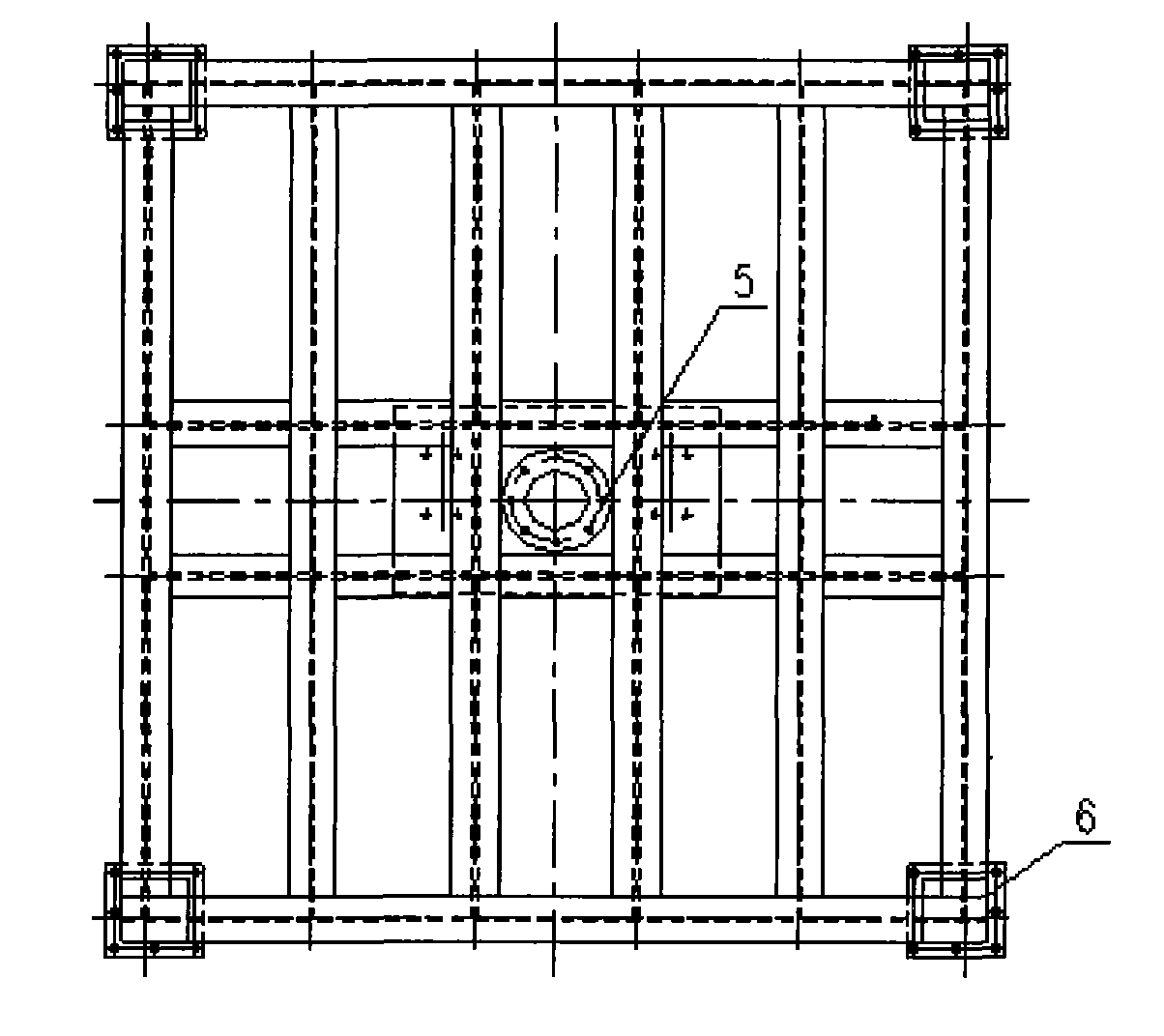

[0035] Such as figure 1 , figure 2 As shown, the double-face pressure interior molding hydraulic press of the present invention is a completely different concept from the frame structure of the traditional hydraulic press. The entire frame is welded and combined by the upper beam 1, the column 6, and the side frame 3, and there is no lower beam structure pieces, the uprights 6 are placed directly on the ground plane. The upper oil cylinder 5 is installed on the upper beam 1, and the piston end of the upper oil cylinder 5 is connected with the upper slider 2; the front row of columns 6 and the rear row of columns 6 are respectively connected with side frames 3, and the front row of columns 6 An upper frame and a lower frame structure are respectively formed between the middle and rear columns 6, and the upper and lower guide columns 19, 20 are respectively installed in the upper frame and the lower frame, and the front and rear ends of the upper slider 2 have linear bearings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com