Bicontinuous biomacromolecule ternary nanometer composite material and preparation method thereof

A nanocomposite material and biopolymer technology, which is applied in the field of biodegradable polymer ternary nanocomposite materials, can solve the problems of large phase domains of blended materials, failure to reflect the superior performance of components, and expensive block copolymers. , to achieve the effect of simple and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

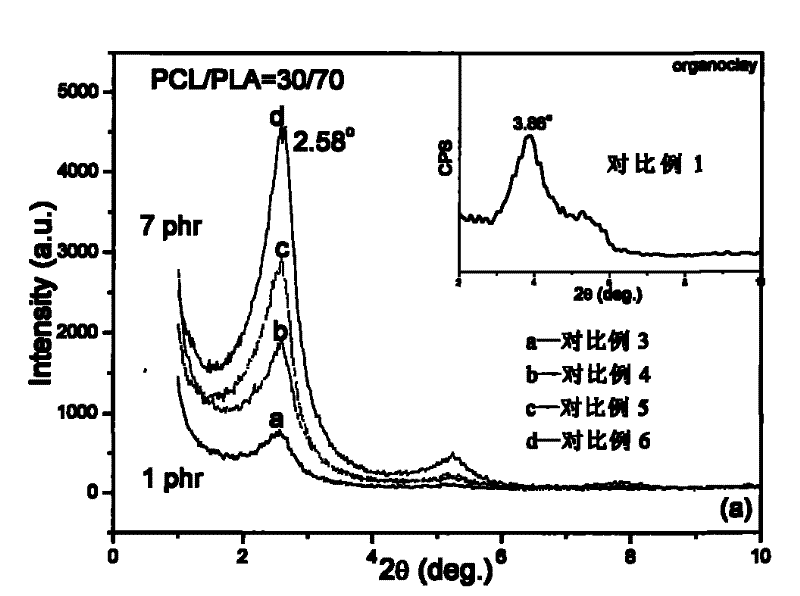

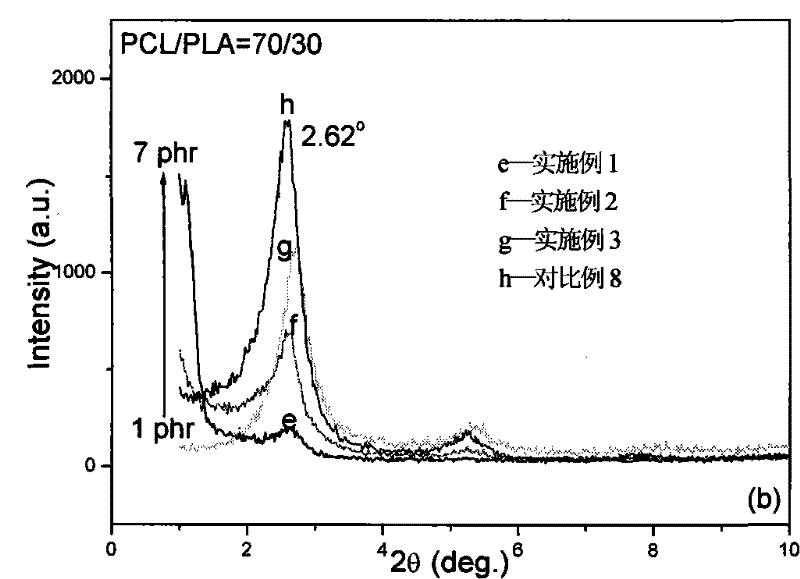

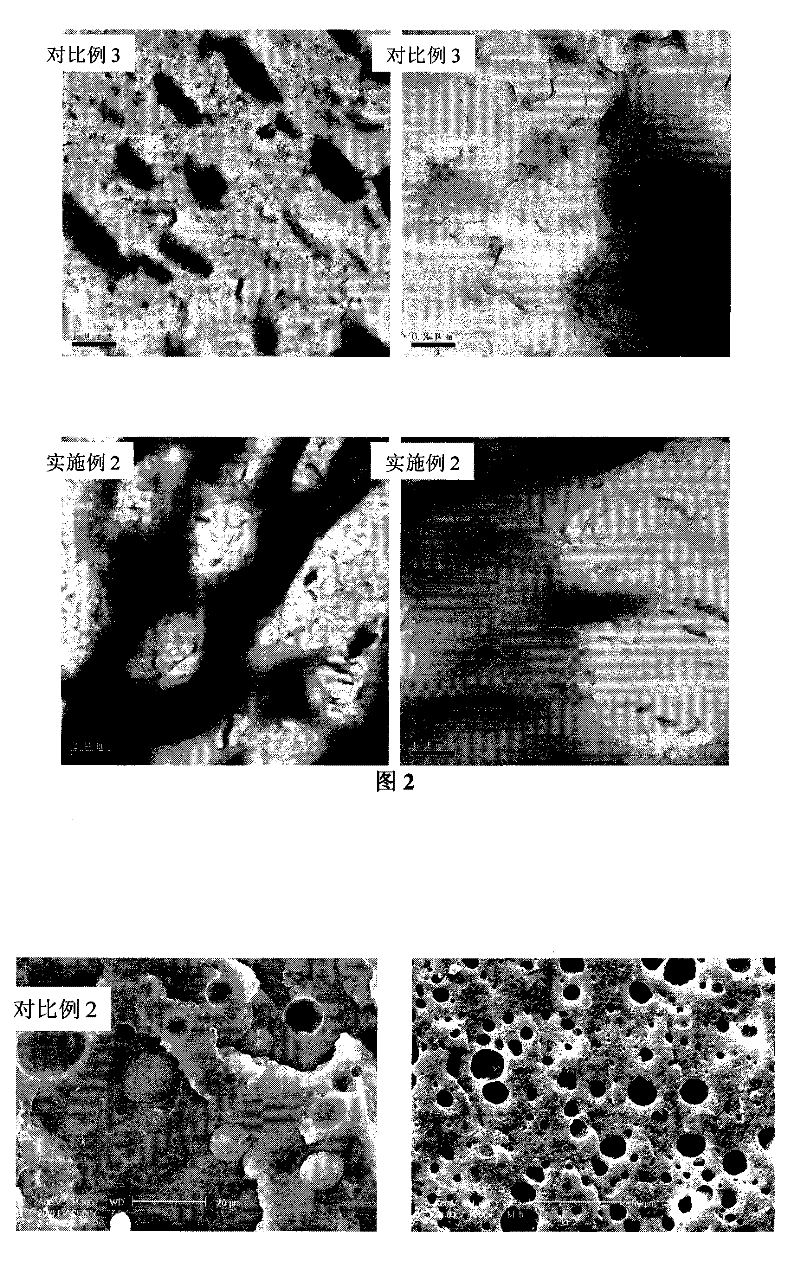

[0021] Add 70 parts of polycaprolactone, 30 parts of polylactic acid and 1 part of organic montmorillonite modified by methyl bis (2-hydroxyethyl) hydrogenated tallow ammonium chloride into the internal mixer, at a temperature of 160 ° C 1. Melting and blending for 8-10 minutes at a rotor speed of 50 rpm to obtain a bicontinuous biopolymer ternary nanocomposite material.

Embodiment 2

[0023] Add 70 parts of polycaprolactone, 30 parts of polylactic acid and 3 parts of organic montmorillonite modified by methyl bis (2-hydroxyethyl) hydrogenated tallow ammonium chloride into the internal mixer, at a temperature of 180 ° C 1. Melting and blending for 8-10 minutes at a rotor speed of 50 rpm to obtain a bicontinuous biopolymer ternary nanocomposite material.

Embodiment 3

[0025] Add 70 parts of polycaprolactone, 30 parts of polylactic acid and 5 parts of organic montmorillonite modified by methyl bis (2-hydroxyethyl) hydrogenated tallow ammonium chloride into the internal mixer, at a temperature of 170 ° C 1. Melting and blending for 8-10 minutes at a rotor speed of 50 rpm to obtain a bicontinuous biopolymer ternary nanocomposite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com