Power transmission line energy-saving capacity-increasing wire and preparation method thereof

A technology of transmission lines and wires, which is applied in the direction of cable/conductor manufacturing, circuits, conductors, etc., can solve the problems of negative impact on the overall performance of wires, complex filling parts, and inconspicuous energy-saving effects, so as to improve mechanical strength characteristics, increase Cross-sectional area, effect of dispersing external force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

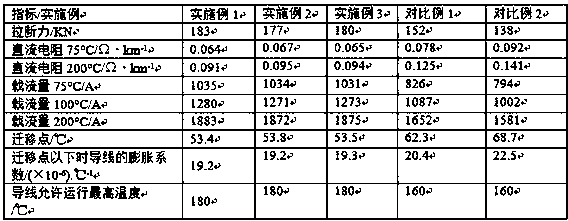

Examples

Embodiment 1

[0029] The energy-saving and capacity-increasing conductor of the power transmission line includes a carbon fiber composite core and an aluminum wire wound outside the carbon fiber composite core. The core is twisted, and the fine carbon fiber core is made of the following raw materials in parts by weight: 15 parts of carbon fiber, 60 parts of epoxy resin, 8 parts of polydimethylsiloxane, 5 parts of dimethyldichlorosilane, toluene 3 parts of diisocyanate, 2.3 parts of nano-zinc oxide, 0.5 parts of polydopamine, 2.0 parts of curing agent, and 42 parts of solvent.

[0030] The aluminum wire is an annealed aluminum wire with a conductivity of 63% IACS.

[0031] The isolation layer is made of glass fiber strands, and the glass fiber strands are alkali-free glass fiber strands.

[0032] The diameter of the glass fiber filament is 9-15 μm, and the density is 2.5-3.0 g / cm 3 , tensile strength 3200-3300MPa, elastic modulus 70-75GPa.

[0033]The epoxy equivalent g / eq. of the epoxy r...

Embodiment 2

[0046] The energy-saving and capacity-increasing conductor of the power transmission line includes a carbon fiber composite core and an aluminum wire wound outside the carbon fiber composite core. The core is twisted, and the fine carbon fiber core is made of the following raw materials in parts by weight: 10 parts of carbon fiber, 50 parts of epoxy resin, 5 parts of polydimethylsiloxane, 1 part of dimethyldichlorosilane, toluene 1 part of diisocyanate, 0.1 part of nano zinc oxide, 0.01 part of polydopamine, 0.1 part of curing agent, and 30 parts of solvent.

[0047] The aluminum wire is an annealed aluminum wire with a conductivity of 63% IACS.

[0048] The isolation layer is made of glass fiber strands, and the glass fiber strands are alkali-free glass fiber strands.

[0049] The diameter of the glass fiber filament is 9-15 μm, and the density is 2.5-3.0 g / cm 3 , tensile strength 3200-3300MPa, elastic modulus 70-75GPa.

[0050] The epoxy equivalent g / eq. of the epoxy resi...

Embodiment 3

[0062] The energy-saving and capacity-increasing conductor of the power transmission line includes a carbon fiber composite core and an aluminum wire wound outside the carbon fiber composite core. The core is twisted, and the fine carbon fiber core is made of the following raw materials in parts by weight: 20 parts of carbon fiber, 70 parts of epoxy resin, 12 parts of polydimethylsiloxane, 8 parts of dimethyldichlorosilane, toluene 5 parts of diisocyanate, 5 parts of nano-zinc oxide, 1.2 parts of polydopamine, 3.5 parts of curing agent, and 50 parts of solvent.

[0063] The aluminum wire is an annealed aluminum wire with a conductivity of 63% IACS.

[0064] The isolation layer is made of glass fiber strands, and the glass fiber strands are alkali-free glass fiber strands.

[0065] The diameter of the glass fiber filament is 9-15 μm, and the density is 2.5-3.0 g / cm 3 , tensile strength 3200-3300MPa, elastic modulus 70-75GPa.

[0066] The epoxy equivalent g / eq. of the epoxy r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com