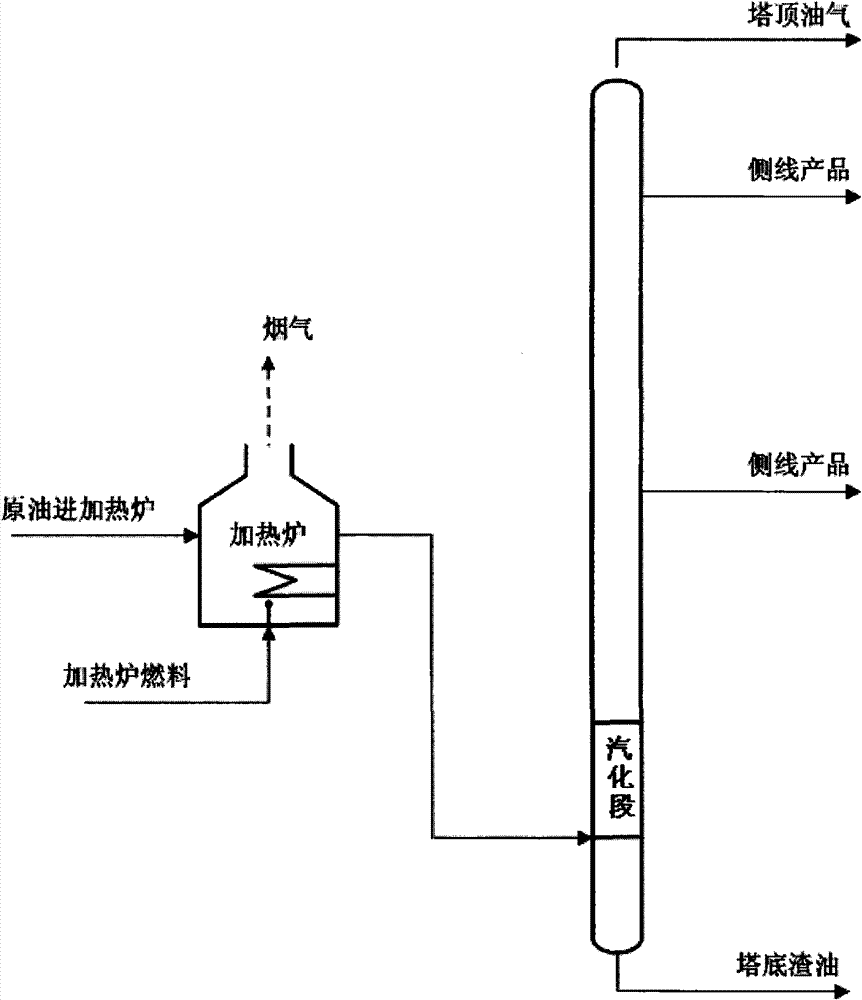

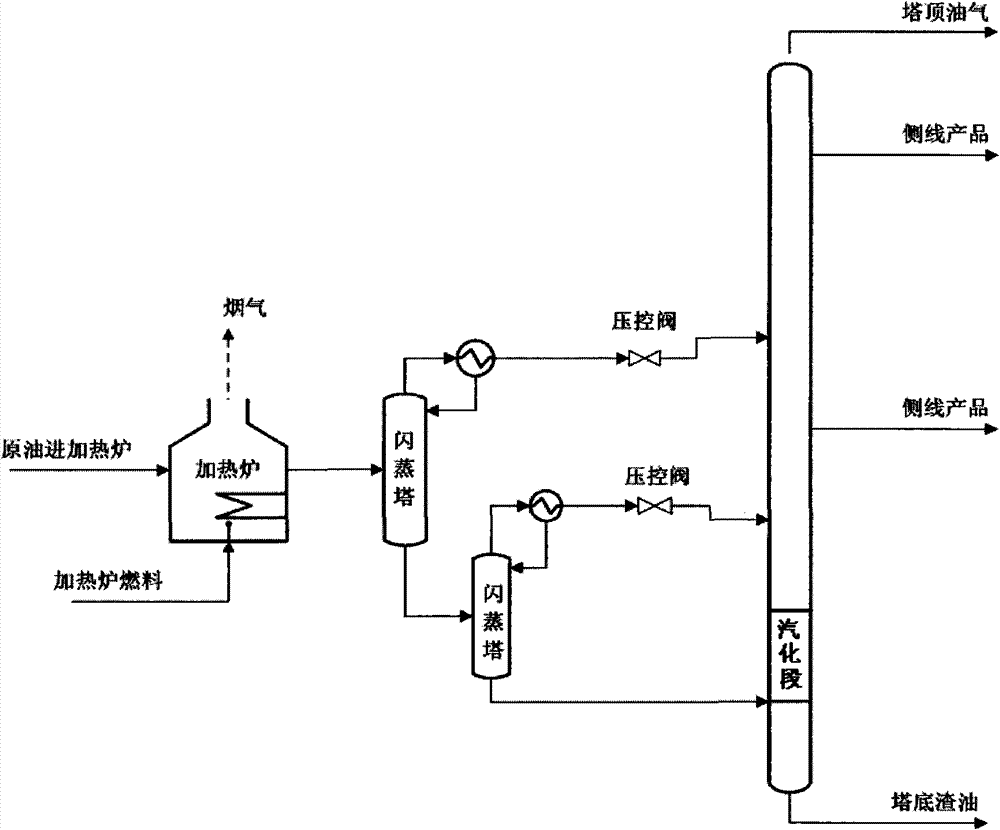

Multi-vaporization feeding method of oil product fractionator

A feeding method and fractionation tower technology, applied in fractionation, hydrocarbon distillation, petroleum industry, etc., can solve problems such as excessive mist entrainment, large vapor phase load, etc., and achieve improved chromaticity, reduced vapor phase load, and vaporization rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention relates to a multiple vaporization feeding method of an oil fractionation tower. The feed of the fractionation tower is high-temperature oil and gas at the outlet of a heating furnace; , adding multi-stage flash towers with different operating pressures and temperatures; the high-temperature oil and gas from the outlet of the heating furnace first enters the flash tower, and the vapor phase of the flash tower enters the position above the vaporization section of the oil fractionation tower after passing through the pressure control valve, and the flash The liquid phase of the distillation tower enters the next flash tower or enters below the vaporization section of the oil fractionation tower; the operating temperature and pressure of each flash tower are respectively within the temperature and pressure range between the outlet of the heating furnace and the vaporization section, And decrease in sequence according to the flow sequence.

[0024] The multi-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com