Double shed needle gauge of half-inch straight line quilting machine

The technology of a quilting machine and double shuttle needles is applied in the field of quilting machines, which can solve the problems such as the inability to meet the requirements of fabric design and pattern, and achieve the effect of increasing the selection range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

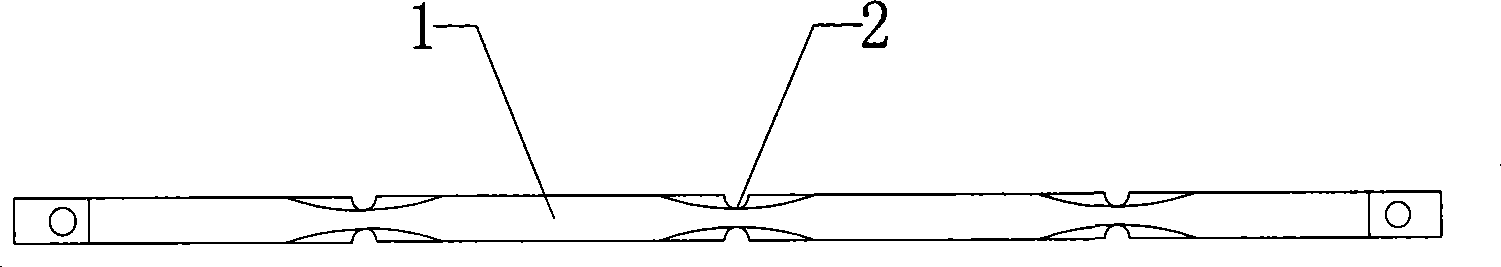

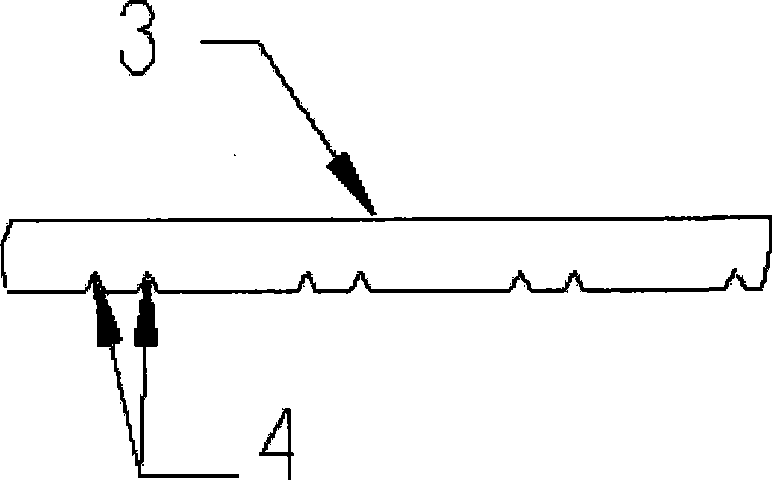

[0011] Such as figure 1 , figure 2 As shown, the double-shuttle gauge 3 of the half-inch linear quilting machine described in the embodiment of the present invention is provided with needle grooves 4 for clamping the left and right knitting needles on the gauge 3 , and the needle grooves 4 of the gauge 3 are connected to the stopper. Plate 1 shed 2 adopts corresponding settings.

[0012] Compared with the commonly used single-shuttle needle gauge, the double-shuttle needle gauge can greatly increase the selection range of patterns that can be made, meet the requirements of different customers for patterns, and adapt to the needs of the market.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com