Substrate capable of evenly distributing equidifferent voltage on surface and high visual-region resistance-type touch screen

A uniform distribution, touch screen technology, applied in the direction of electrical digital data processing, printed circuit components, electrical connection printed components, etc., can solve the problem that the voltage distribution cannot reach a certain level, the resistance uniformity has a great influence, and the accuracy of the click position To achieve the effect of increasing the area of the visible area, uniform distribution of potential difference, and accurate feedback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

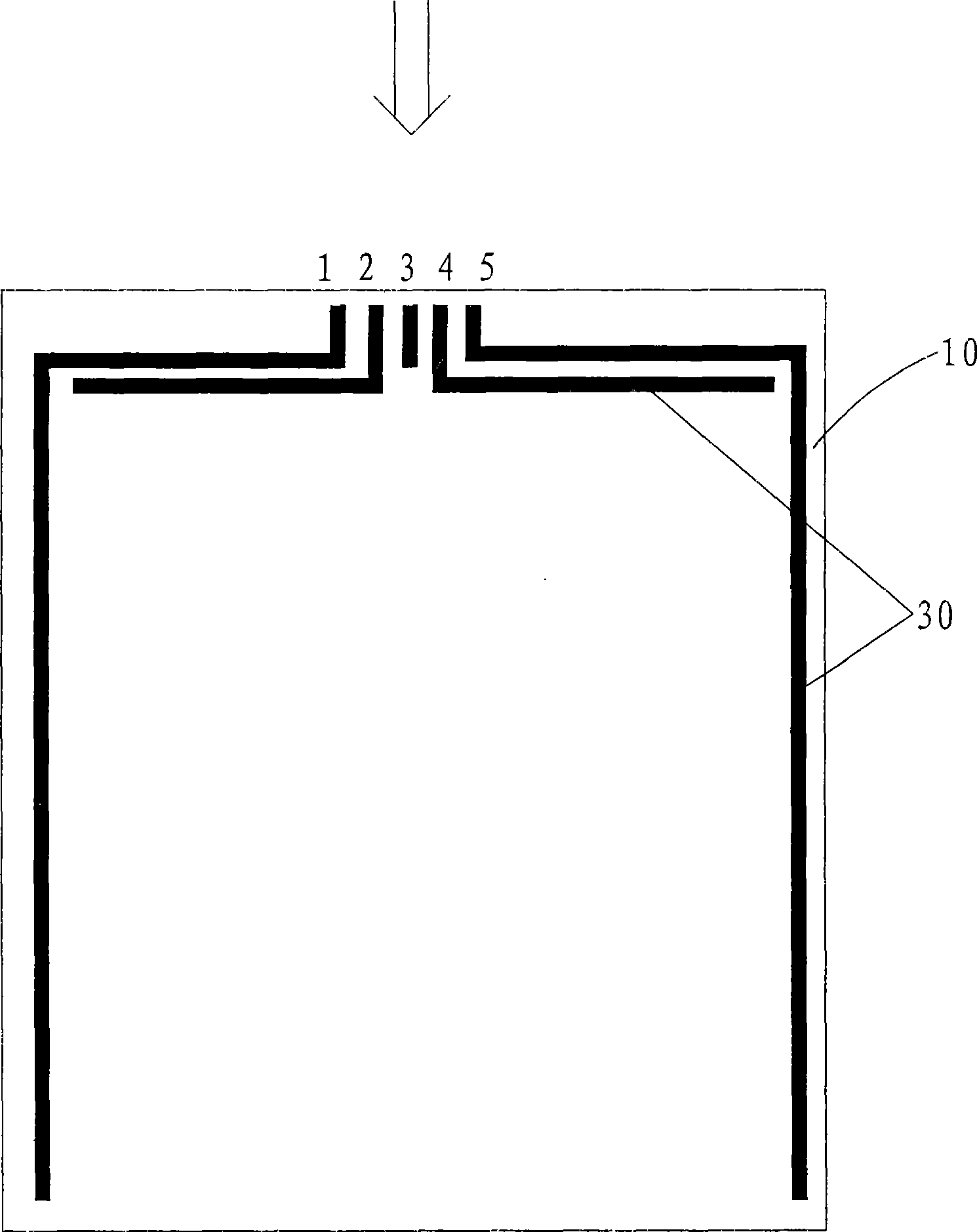

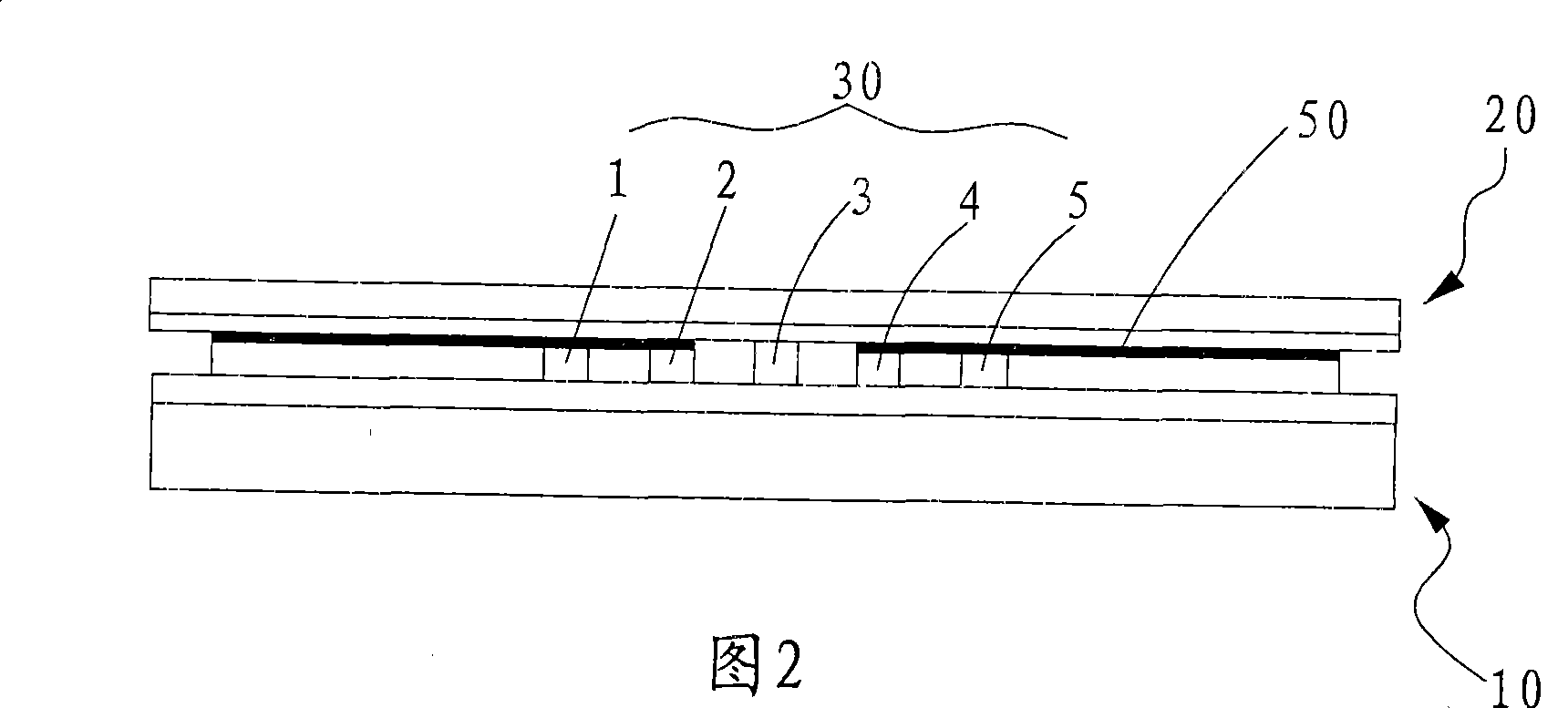

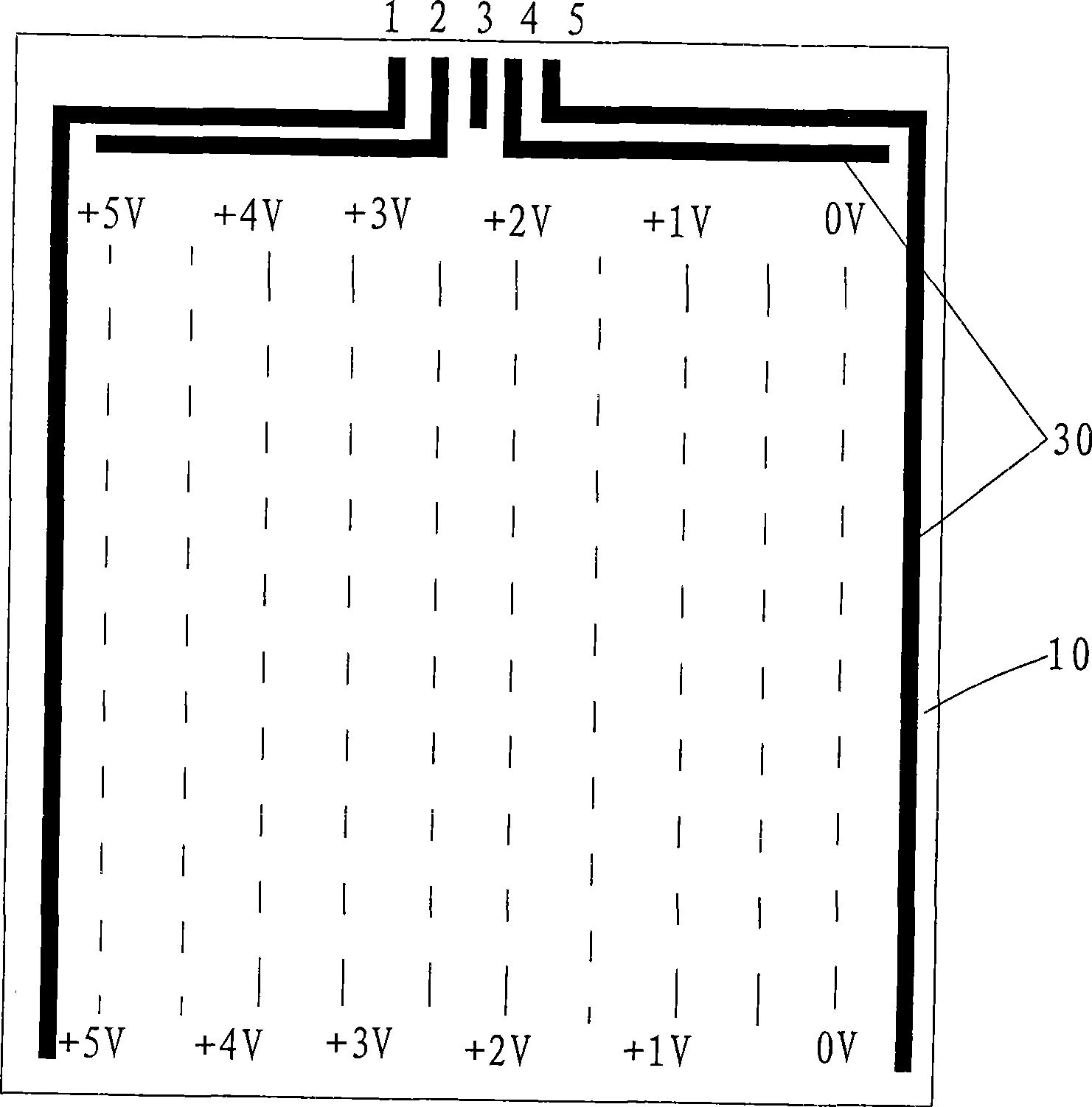

[0038] like Image 6 , 7 As shown, the substrate 10 disclosed by the present invention, which can evenly distribute the differential voltage on the surface, is to arrange at least one layer of discontinuous wires 40 in the form of disconnection on the edge of the substrate 10 . The symmetrical distribution of the discontinuous wires 40 refines the circuit, which can make the distribution of the potential difference more uniform and achieve the purpose of equalizing the voltage. The voltage distribution is mainly affected by the design of the conductive circuit, which greatly reduces the influence of the uniformity of the edge ITO resistance on the voltage distribution.

[0039] Applying this structure to a resistive touch screen with a high viewing area can provide more accurate feedback on the click position of the touch screen and expand the area of the viewing area.

[0040] The application of the substrate 10 of the present invention in a resistive touch screen with a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com