Lapped amorphous core with approximate-circle cross-section

An amorphous iron core, approximately circular technology, applied in the direction of transformer/inductor parts, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problems of easily damaged coil insulation materials, large amount of copper used in coils, etc., to save energy The amount of copper used, the circumference is small, and the effect of overcoming adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

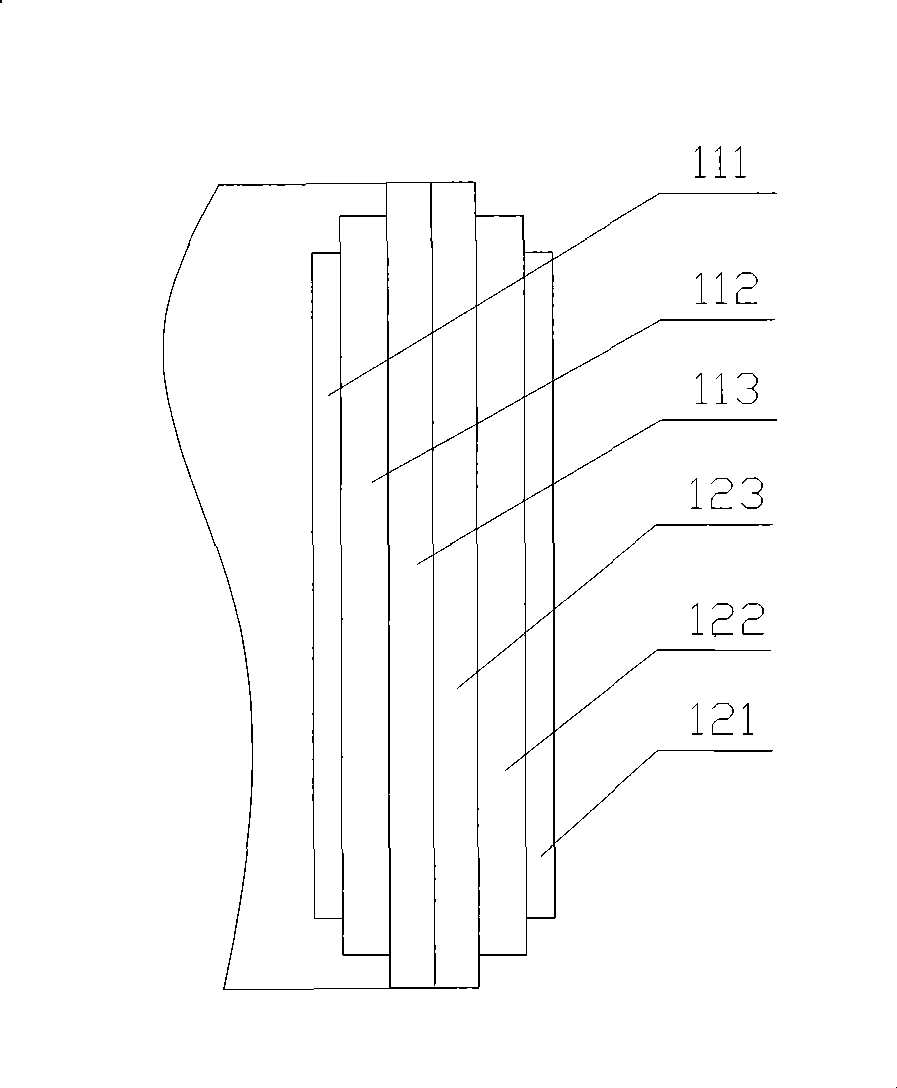

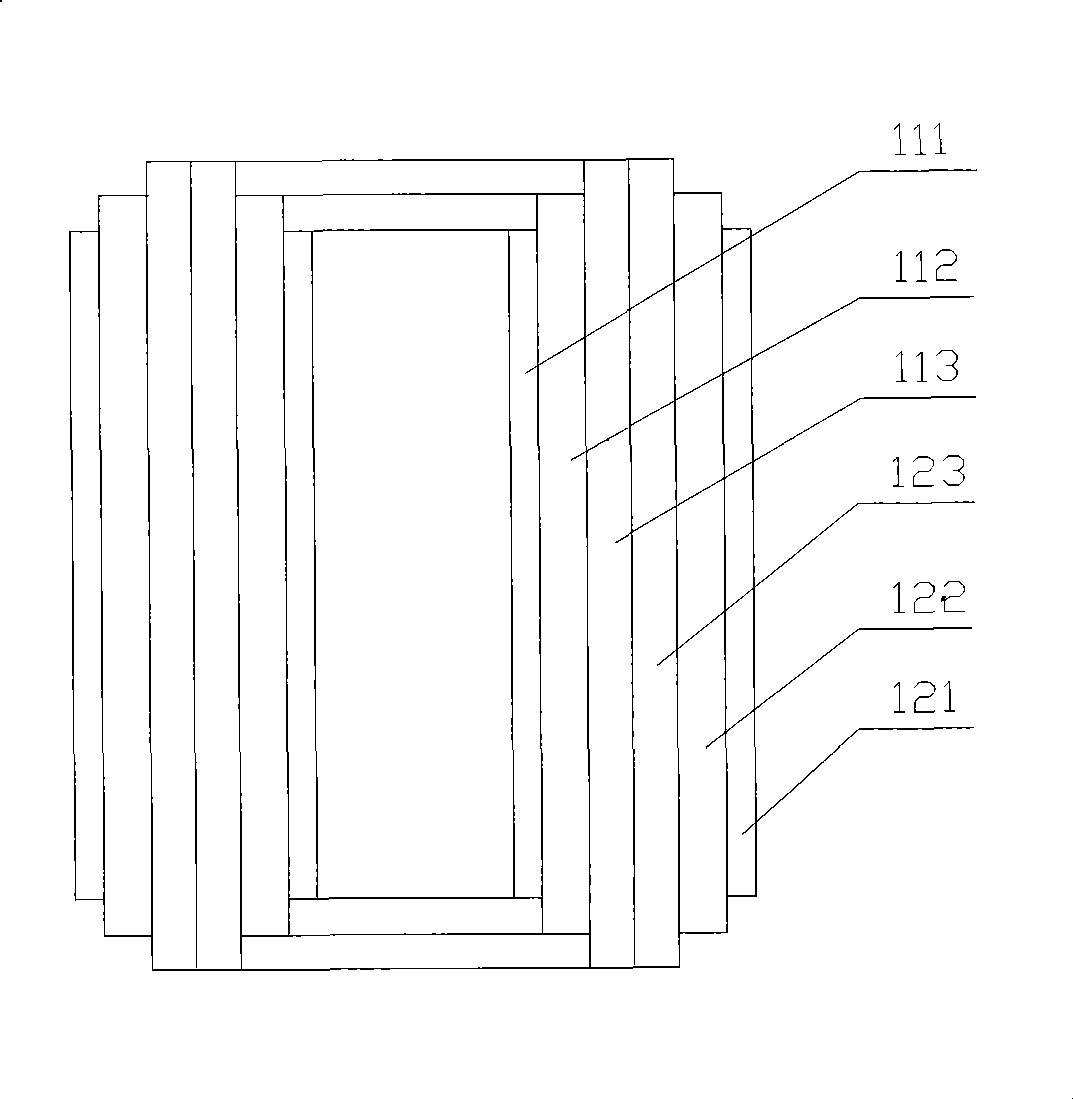

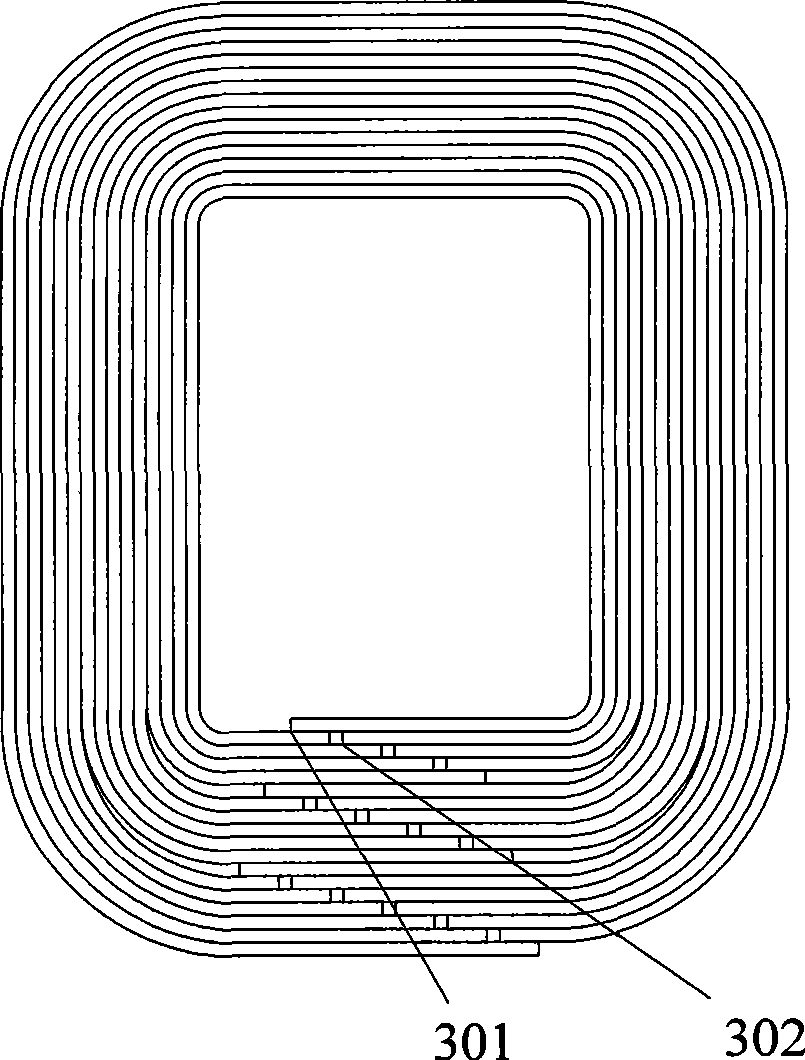

[0009] see Figure 1-3 , the present invention provides a lap-jointed amorphous single core with a nearly circular cross-section, which is formed by stacking several amorphous core sheets in sequence, and is characterized in that the several amorphous core sheets are divided into several overlapping joints with different lengths. The two ends of the same lap group overlap each other in the core joint area to form a lap segment 301, and the lap segment of any lap group is misaligned with the lap segment of the adjacent lap group in the direction of the core tangent , the outer layer end of any overlapping section is butted with the inner layer end of the overlapping section located outside it, leaving a gap 302 between them, and the plurality of amorphous core pieces also have different widths, located The width of the amorphous iron core sheet in the middle part of the column is greater than the width of the amorphous iron core sheet located on both sides of the iron core colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com