Battery pole shoe rectification mechanism

A battery pole piece and deflection correction technology, which is applied in the direction of electrode manufacturing, secondary batteries, battery pack components, etc., can solve problems that affect battery quality, cannot guarantee the consistency of tabs, glue length consistency, etc., to improve battery quality , simple structure and easy implementation

Active Publication Date: 2011-01-05

SHENZHEN YINGHE TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the process of automatic production of lithium battery pole pieces, it is often impossible to guarantee the consistency of the exposed length of the tabs on the pole pieces and the length of the glue when welding the tabs and applying glue due to the deviation of the pole pieces when they are running on the rollers. Consistency, which makes it very difficult for the later processes such as cell winding, which ultimately affects the quality of the battery

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

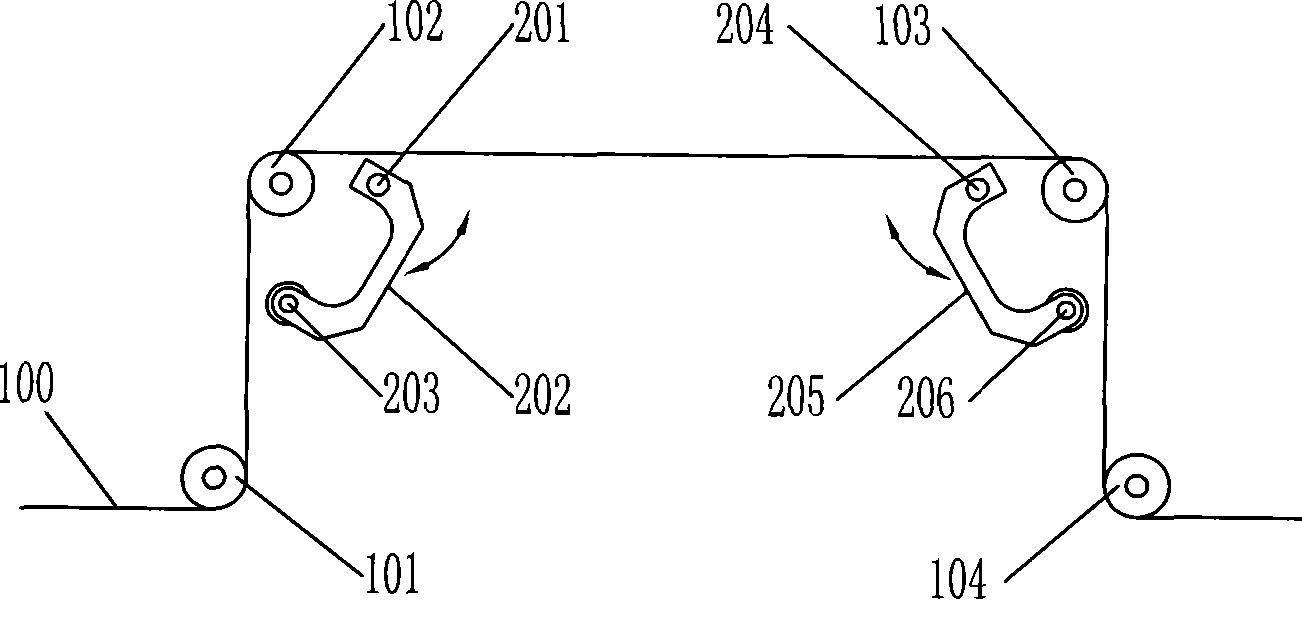

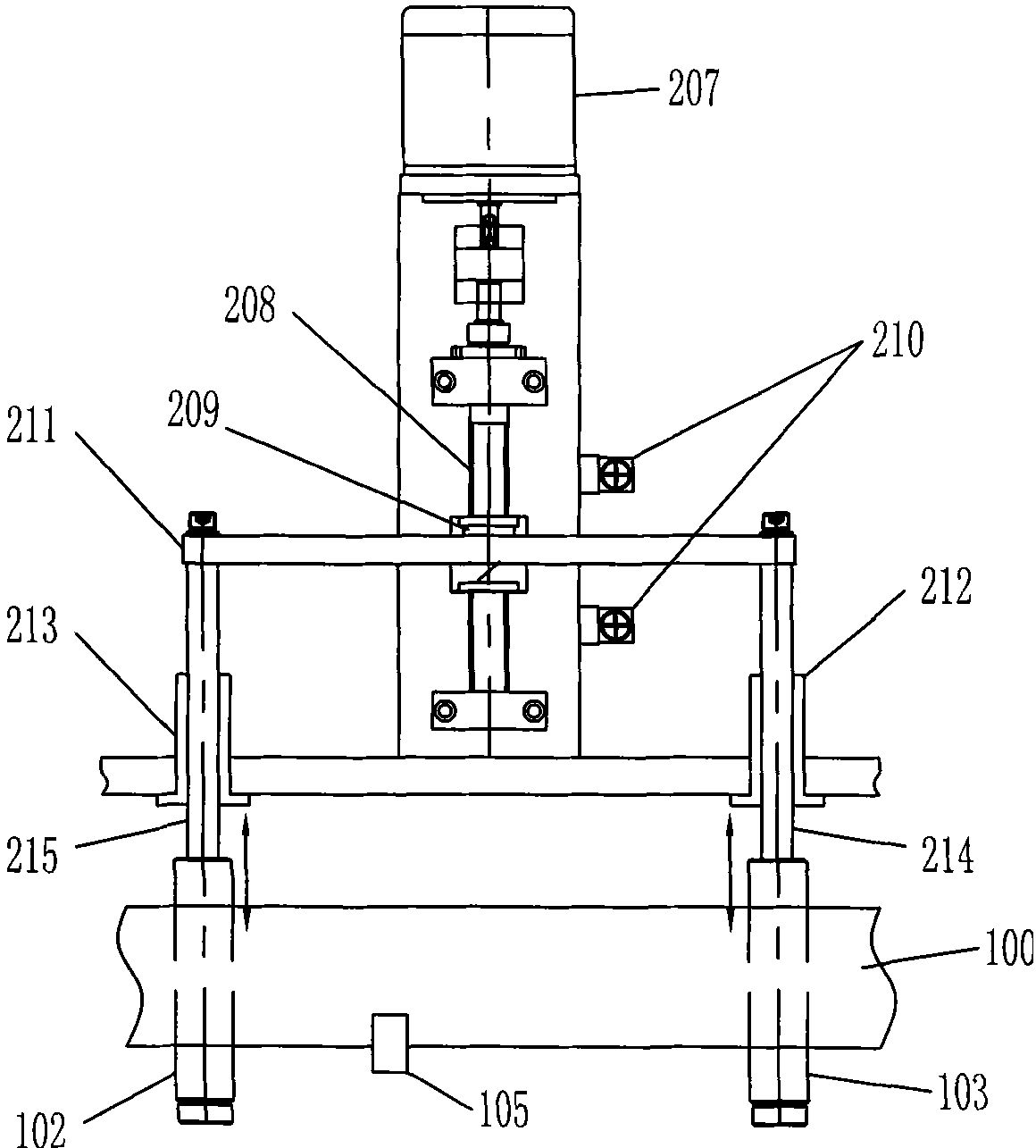

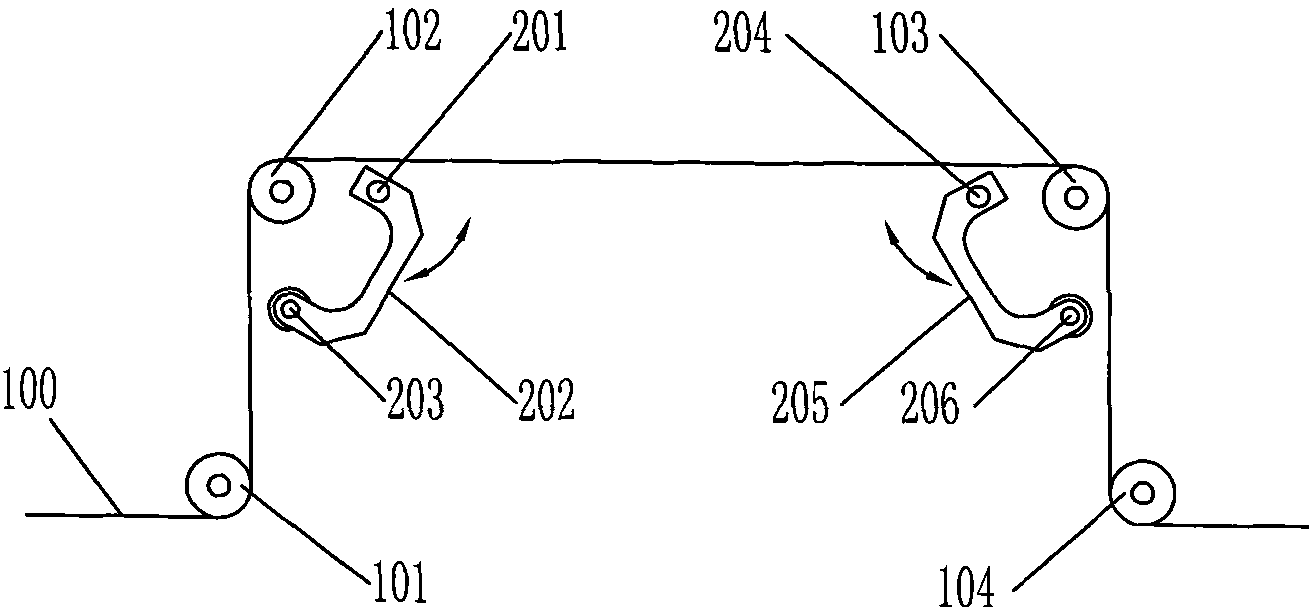

The invention provides a battery pole shoe rectification mechanism which comprises a power plant and a rectifying transition wheel that can reciprocate along a self-axial direction under the driving of the power plant. A position sensor, a spacing sensor and a transition device can also be arranged in the battery pole shoe rectification mechanism. Even the battery pole shoe stops running, the battery pole shoe rectification mechanism can also rectify the position of the pole shoe directly and process the pole shoe at a rectified part, without considering the problems that whether the pole shoe is in a running state and rectification lag, etc. The battery pole shoe rectification mechanism can effectively solve the deflexion problem of the battery pole shoe, ensure the normal proceeding of subsequent procedures and improve the battery quality. The mechanism has the advantages of simple structure, convenient operation and easy implementation.

Description

Battery Pole Sheet Correction Mechanism 【Technical field】 The invention relates to battery manufacturing technology, in particular to a battery pole piece deflection correction mechanism capable of correcting the deflection of the battery pole piece. 【Background technique】 In the process of automatic production of lithium battery pole pieces, it is often impossible to guarantee the consistency of the exposed length of the tabs on the pole pieces and the length of the glue when welding the tabs and applying glue due to the deviation of the pole pieces when they are running on the rollers. Consistency, resulting in a great deal of difficulty in the later processes such as cell winding, which ultimately affects the quality of the battery. 【Content of invention】 The technical problem to be solved by the present invention is to provide a battery pole piece deflection correction mechanism that can correct the deflection of the battery pole piece. In order to solve the above...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M4/04H01M2/20H01M10/38H01M50/536

CPCY02E60/12Y02E60/10Y02P70/50

Inventor 许小菊王胜玲蔡实艳

Owner SHENZHEN YINGHE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com