A furnace temperature uniformity test tool and test bracket

A technology for testing tooling and uniformity. It is applied in the field of furnace temperature uniformity testing tooling and test brackets. It can solve the problems of detection failure, inability to truly detect the temperature gradient of the mesh belt furnace, and inability to test the temperature environment of the muffle tube.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

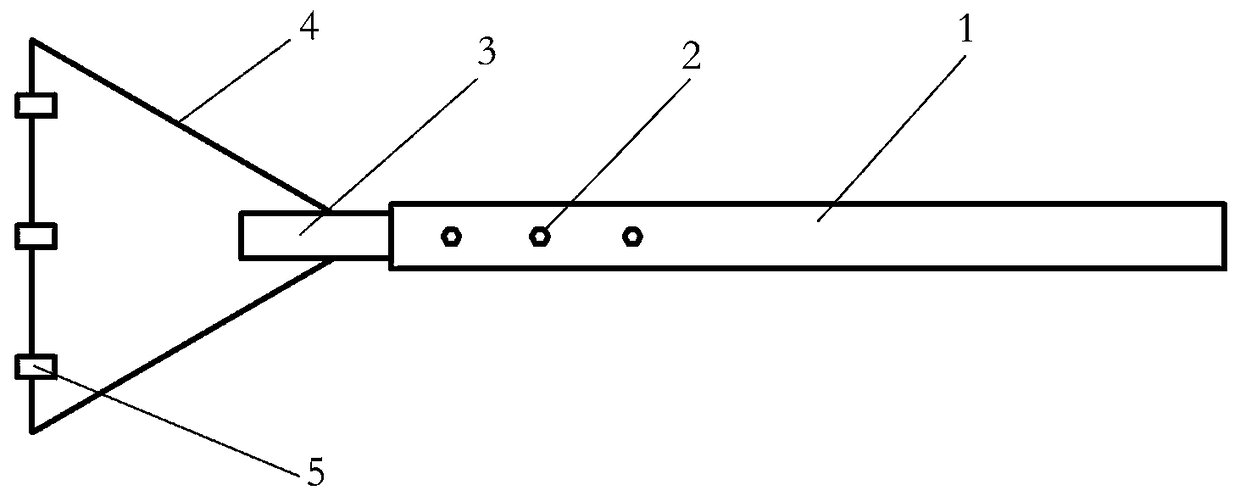

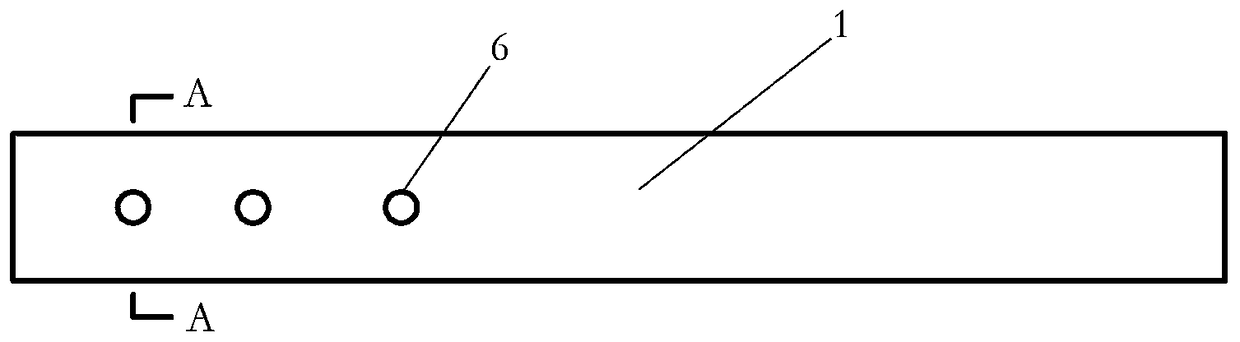

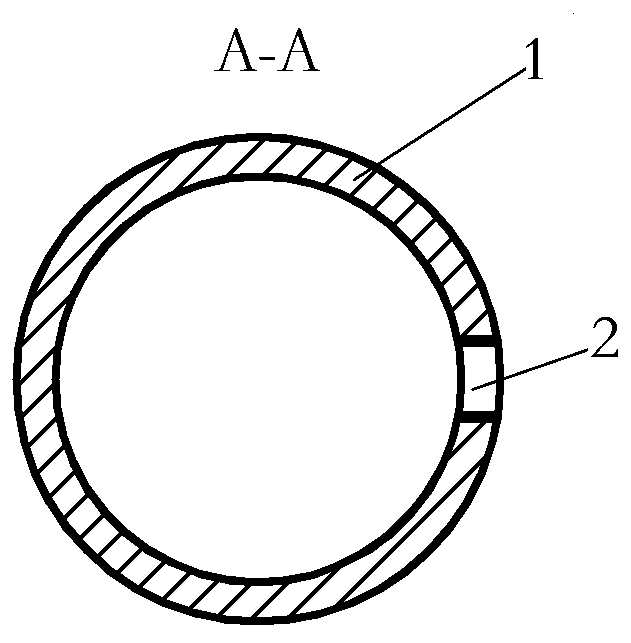

[0024] A kind of furnace temperature uniformity testing tool of the present invention, such as figure 1 As shown, it includes a test rod, a temperature measuring fixture arranged at the front end of the test rod, and a thermocouple installed on the temperature measuring fixture. The inner cylinder 3 inside the cylinder 1 and can move back and forth relative to the outer cylinder 1, such as Figure 2-5 As shown, the outer cylinder 1 and the inner cylinder 3 are positioned and fixedly connected by fastening screws 2 . The wall of the outer cylinder 1 is provided with three screw holes 6 for mounting the fastening screws 2, and the temperature measuring fixture is arranged at the front end of the inner cylinder 3. In this embodiment, the temperature measuring fixture is a tripod 4 in an isosceles triangle shape. ,Such as Figure 6-7 Said, the apex 4-1 of the tripod 4 is connected with the front end of the inner tube 3, the bottom 4-2 of the tripod 4 is perpendicular to the axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com