Connection device of vertical hydraulic press main plunger and pressure head

A vertical hydraulic press and connecting device technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of serious eccentric wear of the copper sleeve and seal of the master cylinder, limiting the rotation range of the indenter, and the eccentric load of the press. The effect of being frequently cut off, increasing the rotation range, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

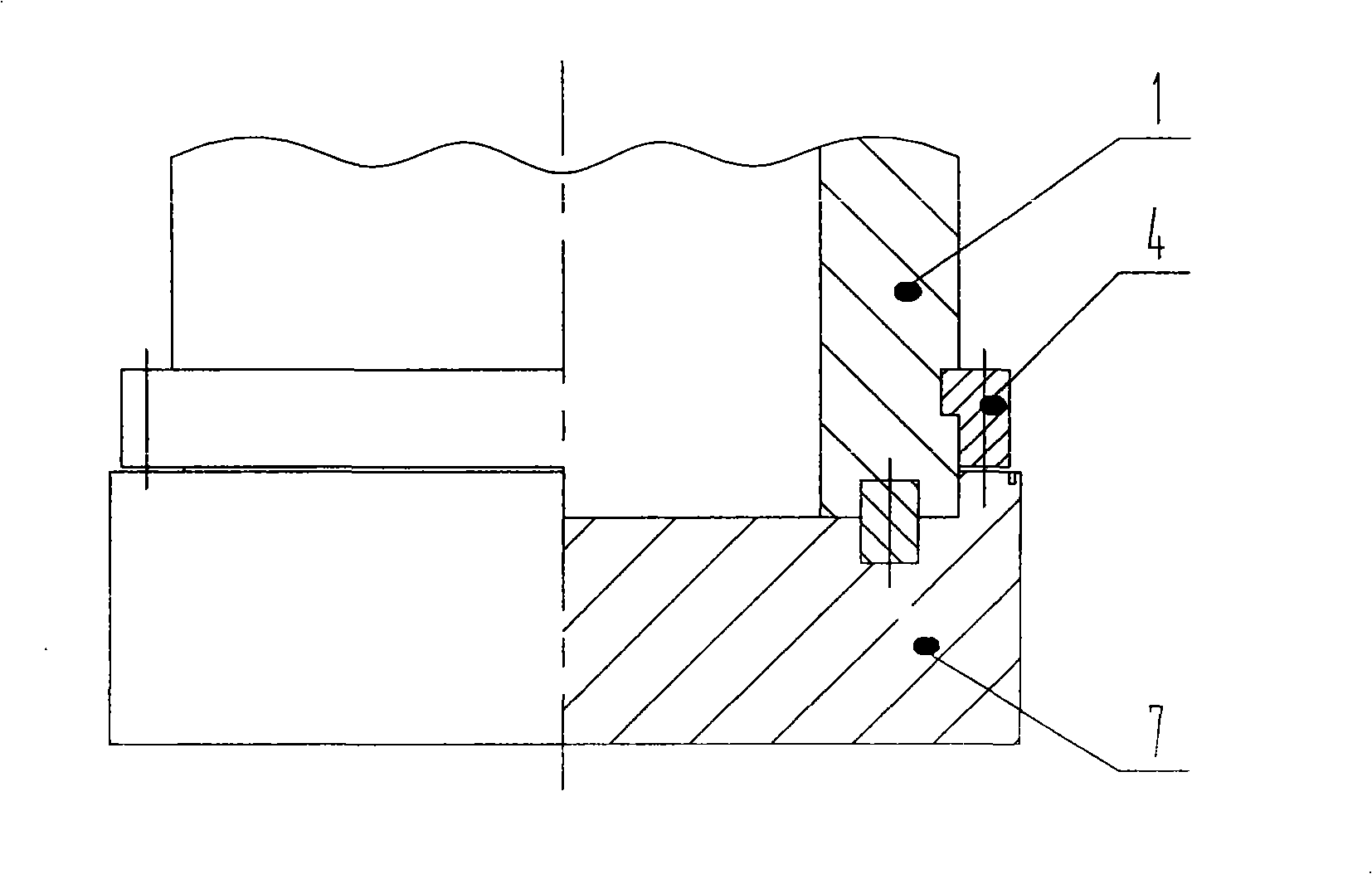

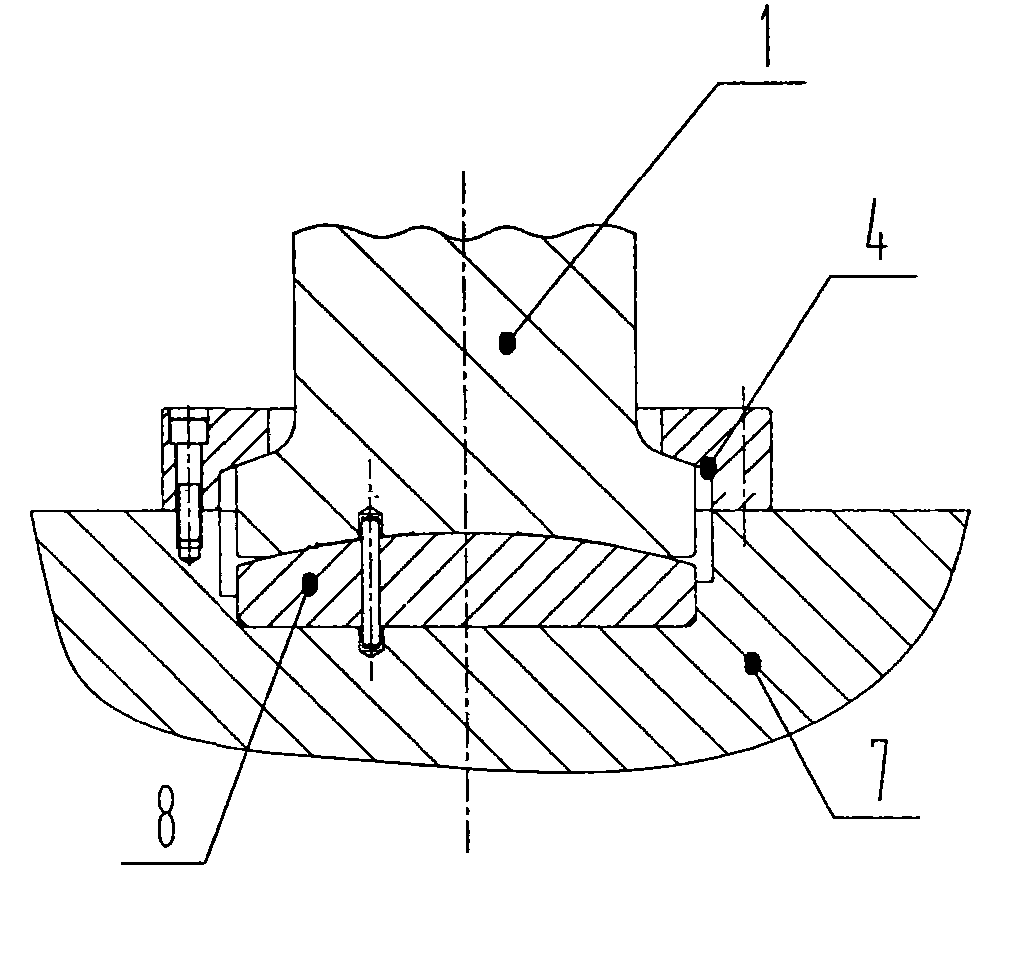

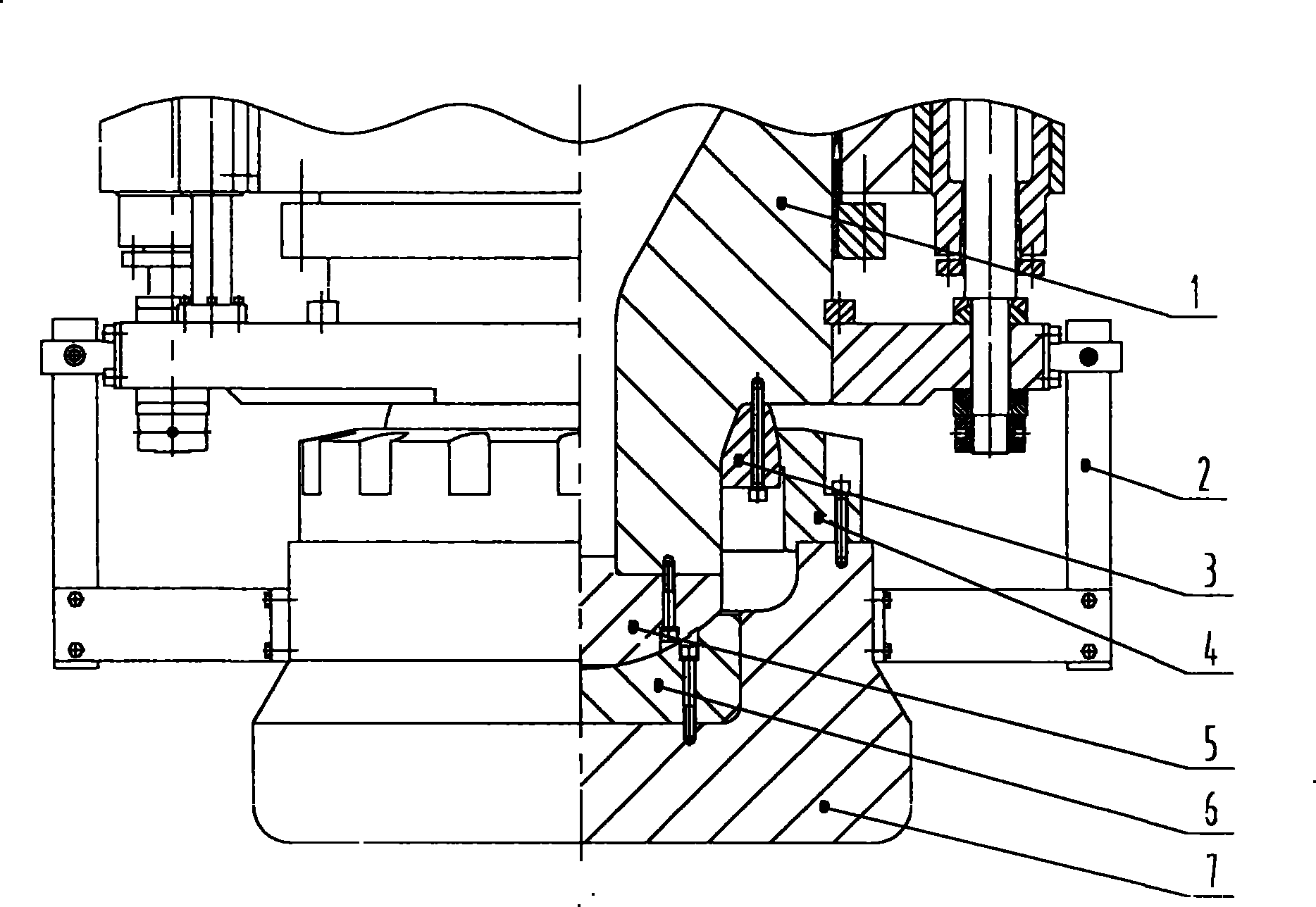

[0016] Such as image 3 As shown, a connection device between the main plunger and the pressure head of a vertical hydraulic machine, the main plunger 1 is in contact with the spherical surface of the upper spherical body 3 and connected by bolts, and the plane of the main plunger 1 and the lower spherical body 5 is connected by bolts , the upper and lower spherical surfaces have the same spherical center, the main plunger 1 forms a discontinuous sphere with the upper and lower spherical surfaces; the indenter 7 and the plane of the spherical support pad 6 are connected by bolts, and the spherical surface of the spherical support pad 6 is in contact with the spherical surface of the lower spherical body 5 , the pressure flange 4 and the pressure head 7 are connected by bolts, the side surface of the pressure flange 4 is in contact with the side surface of the upper spherical body 3, and the pressure head 7 forms a discontinuous inner sphere with the pressure flange 4 and the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com