dual drive compressor

A compressor and dual-drive technology, applied in the field of compressors, can solve the problems of low compressor operating speed, long switching time, small transmission ratio, etc., and achieve the effects of reducing impact, improving user experience, and improving smooth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

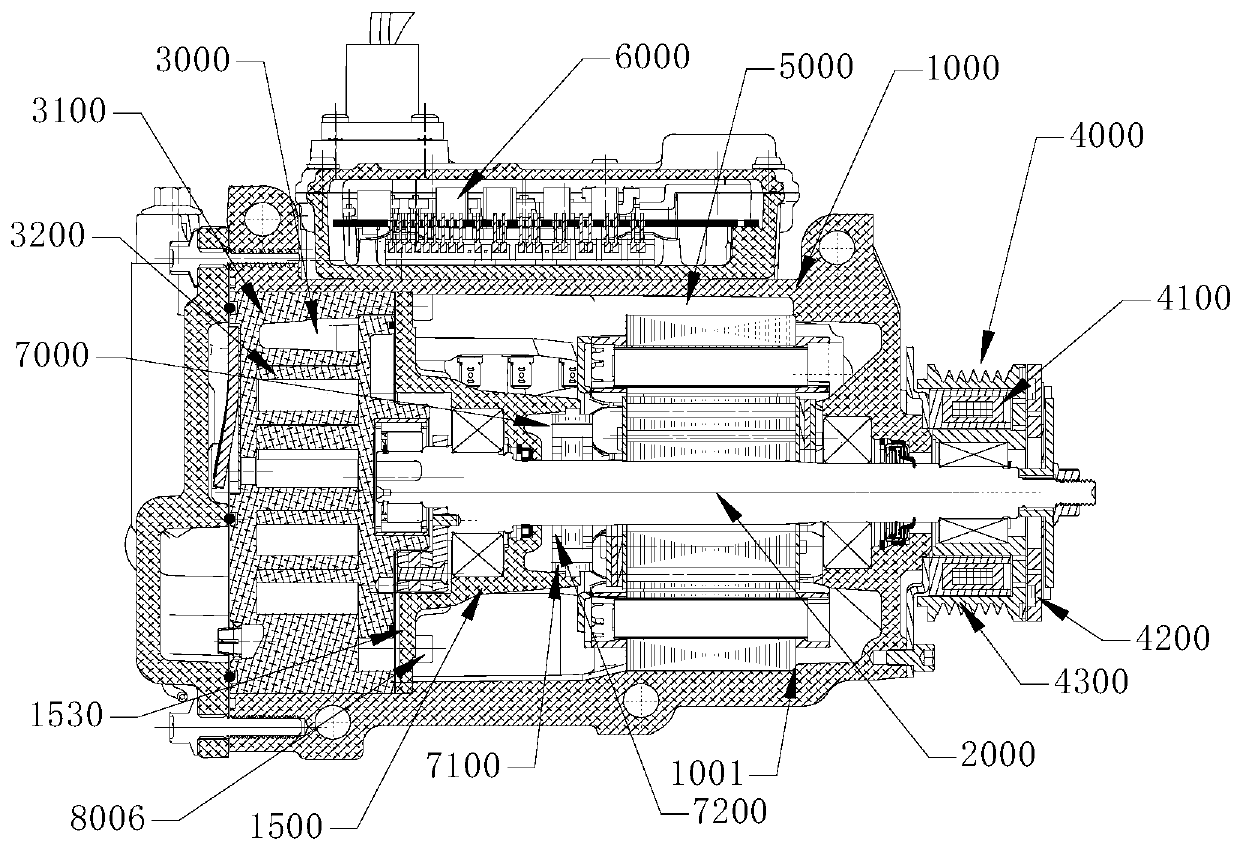

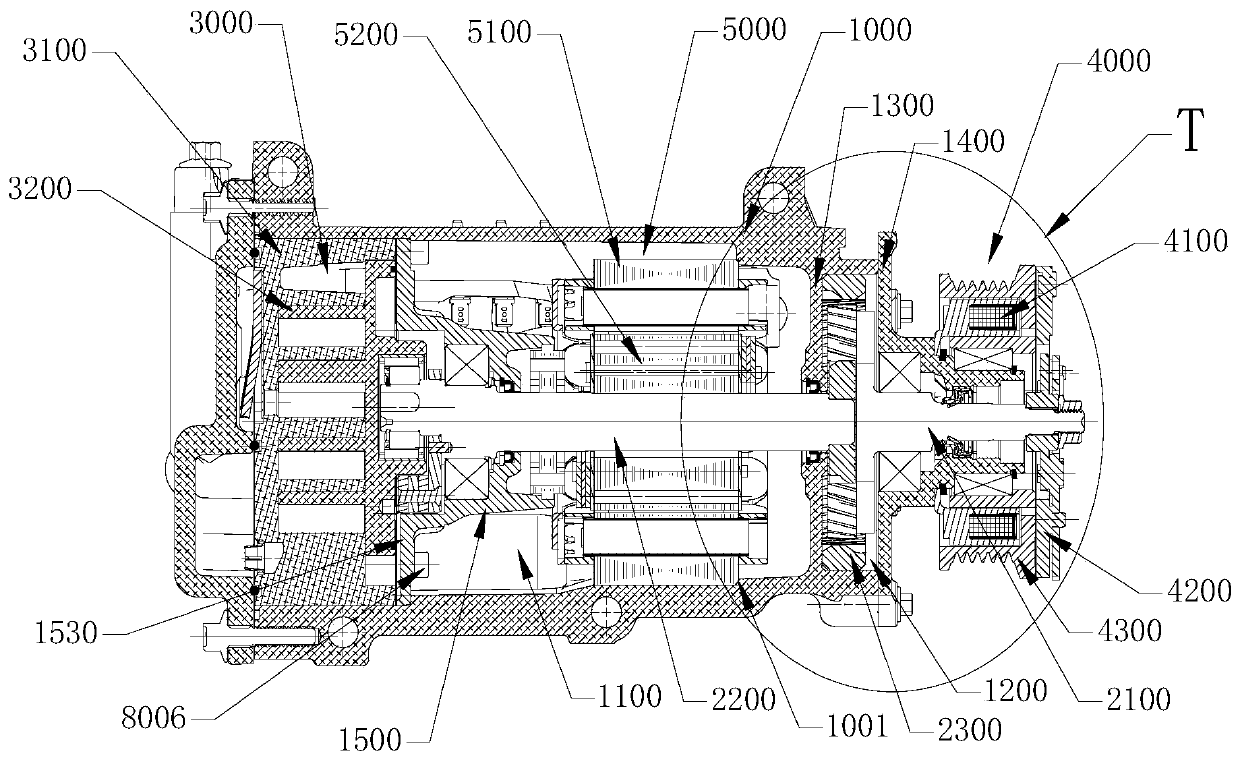

[0066] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

[0067] In this disclosure, for the convenience of description, the orientation words used such as "front and rear" are defined by the inventor according to a specific structure, for example, as far as the crankshaft is concerned, in its axial direction In terms of direction, the end connected to the clutch assembly is the front, and the opposite end is the rear; "inner and outer" generally refer to the contours of the corresponding parts.

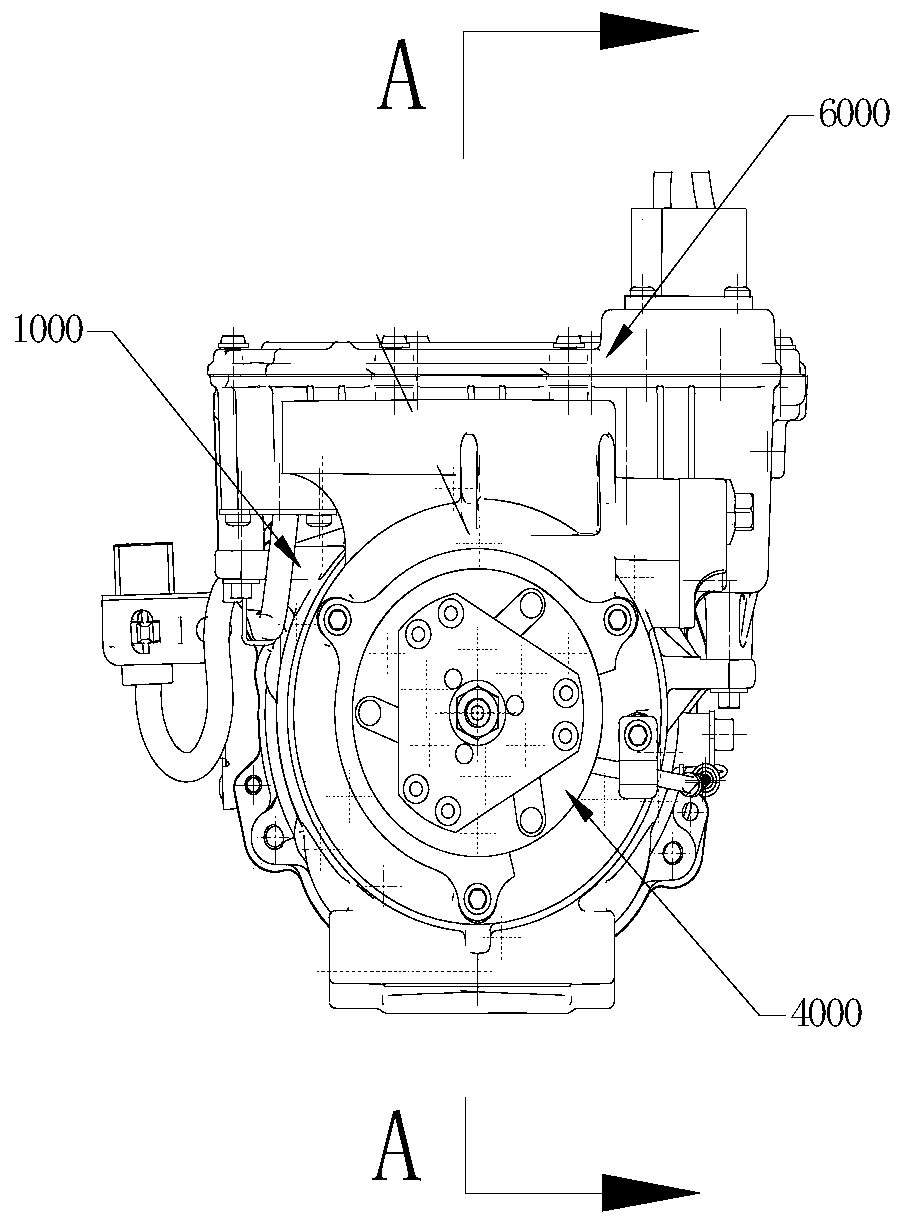

[0068] The present disclosure provides a dual-drive compressor, combined with figure 1 and figure 2 Firstly, the basic structure and working principle of the dual-drive compressor are introduced.

[0069] Such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com