Low or non oxidizing heat accumulating type burner

A burner, non-oxidation technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of affecting the installation space of the furnace body, bulky shape, and low airflow ejection speed, so as to improve energy utilization. , The effect of improving the operating environment and increasing the injection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention more clear, the implementation of the present invention will be described in detail below in conjunction with specific embodiments and corresponding drawings. It is stated here that the exemplary embodiments and descriptions of the present invention are only used as explanations of the present invention, not as limitations of the present invention.

[0034] The low-oxidation and non-oxidative regenerative burner provided by the present invention is suitable for gas fuels, especially gas fuels with high calorific value such as liquefied gas and natural gas, and is mainly used for galvanizing furnaces, heat treatment furnaces, and steel rolling heating furnaces that require less and no oxidation to heat workpieces. , Forging furnaces and other industrial furnaces.

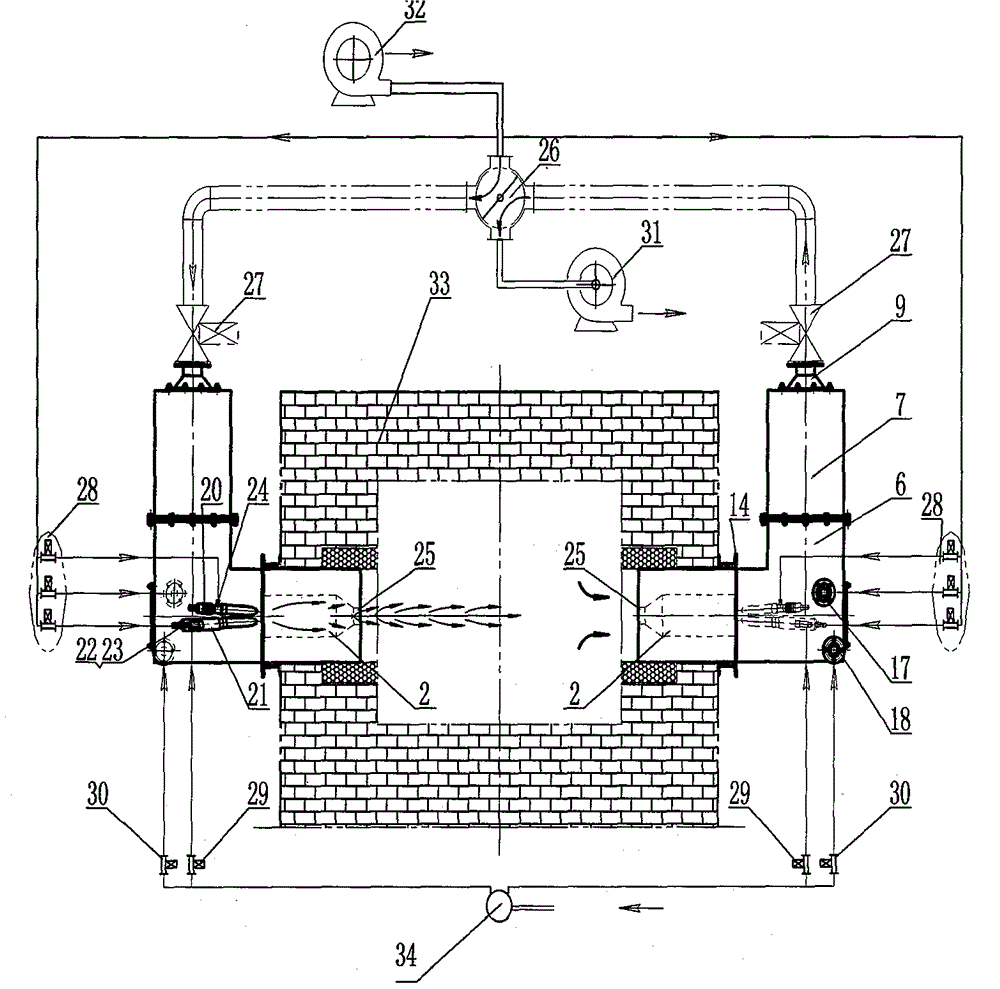

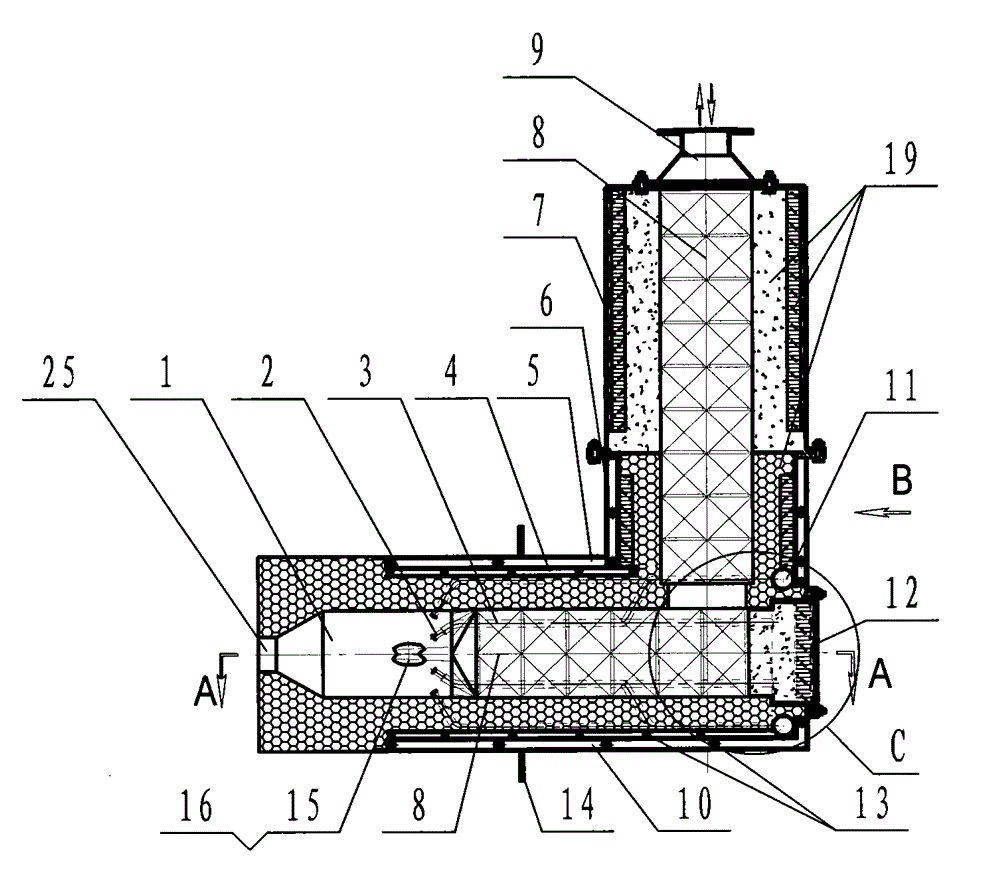

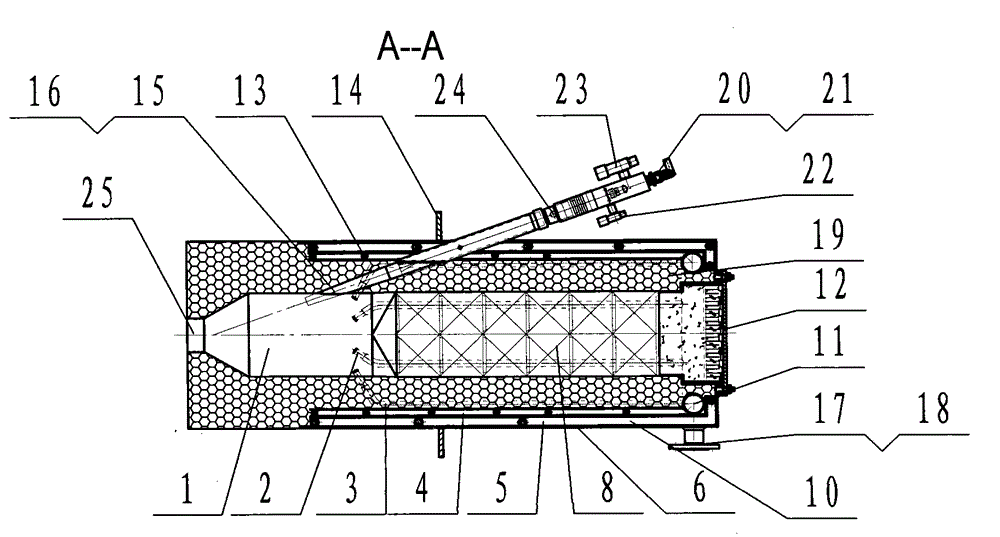

[0035] combine figure 1 , figure 2 , image 3 and Figure 4 As shown, the less non-oxidizing regenerative burner is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com