High power LED light source unit for lighting integrated with heat radiator

A technology for LED lighting and light source units, applied in the field of high-power LED lighting light source units, can solve the problems of light source structure, lightening degree, etc., and achieve the effects of not easy heat accumulation, prolonging service life, and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

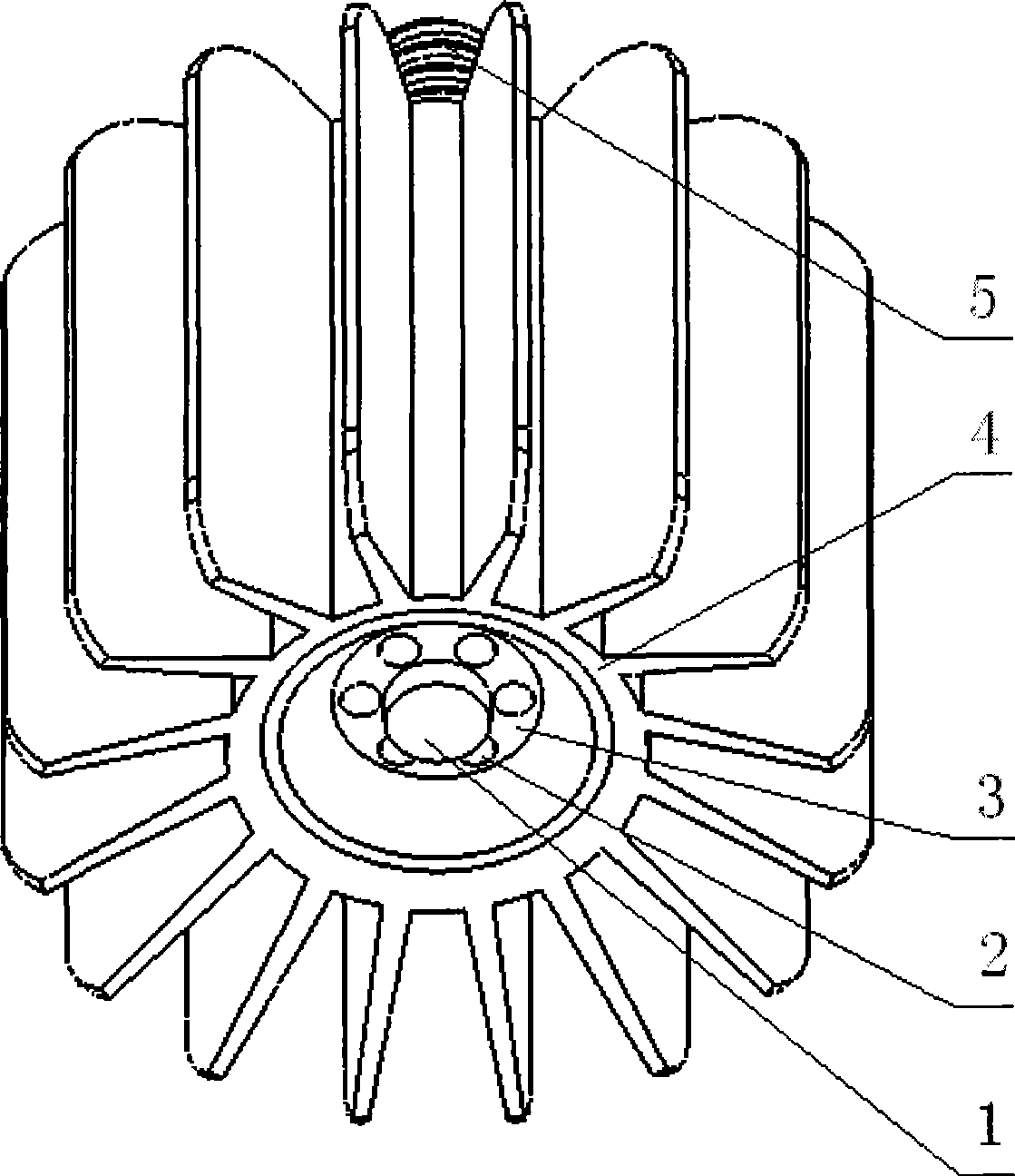

[0022] Such as figure 1 As shown, a high-power LED lighting source unit integrated with a radiator includes a cylindrical aluminum radiator 4 with sixteen cooling fins around it, and a high-power LED1, and the positive and negative poles are led out by circuit connection, and at the other end of the radiator 4 corresponding to the LED mounting surface, there is an external thread light source connector that is connected to the positive and negative poles of the LED and can be flexibly connected with the matching internal thread lamp interface 5. On the main body of the heat sink 4 near where the LED is installed, there are six through holes 2 through which both ends pass through along the axial direction of the heat sink 4 .

[0023] It has been proved by tests that the LED lighting fixture of the present utility model really solves the problem, realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com