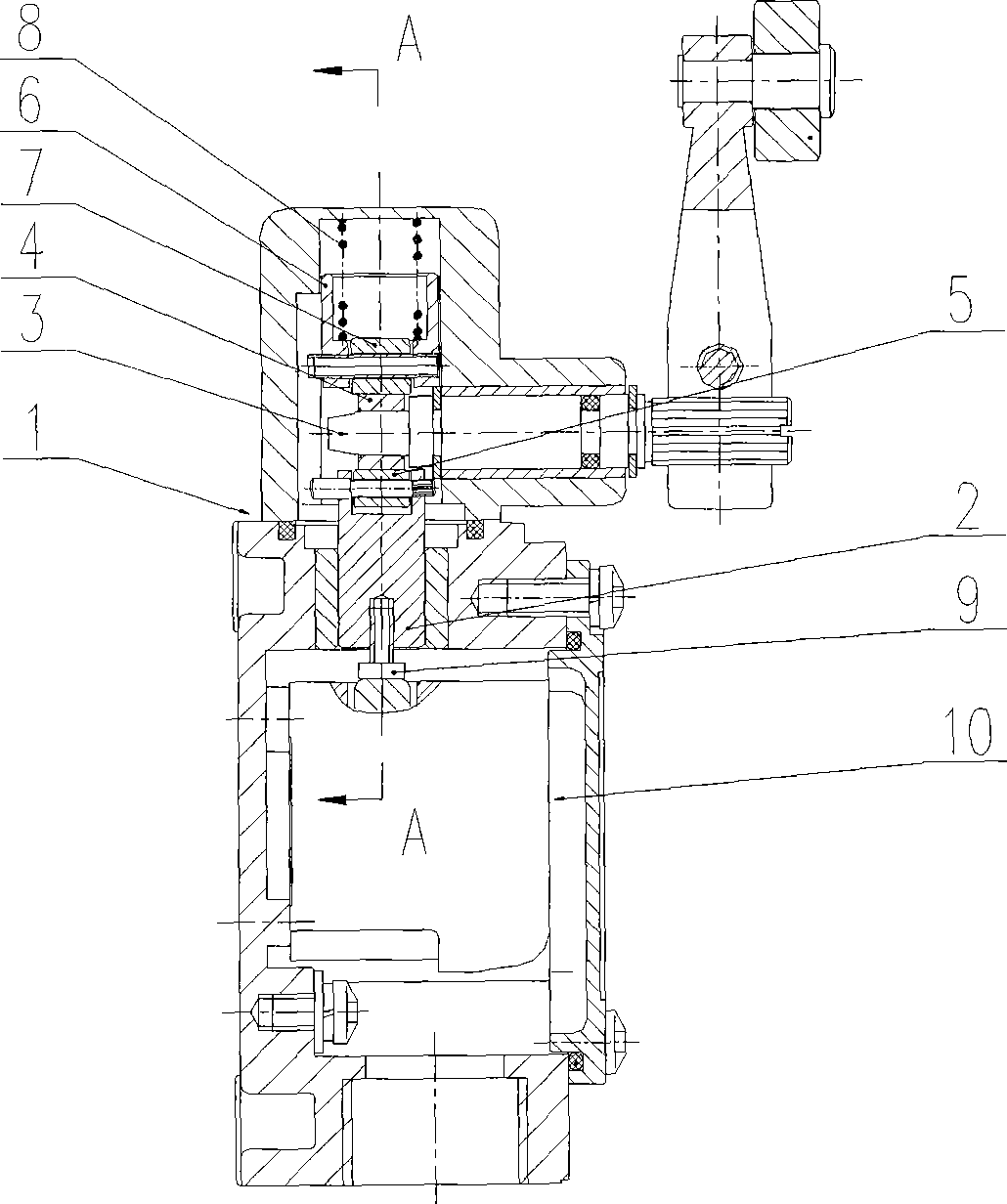

Reverse rolling fork type operating device for travel switch

A technology of travel switches and actuators, applied in the direction of electrical components, etc., can solve problems such as imperfect protection functions, mechanism jamming, and action failures, and achieve the effects of compact structure, reliable operation, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

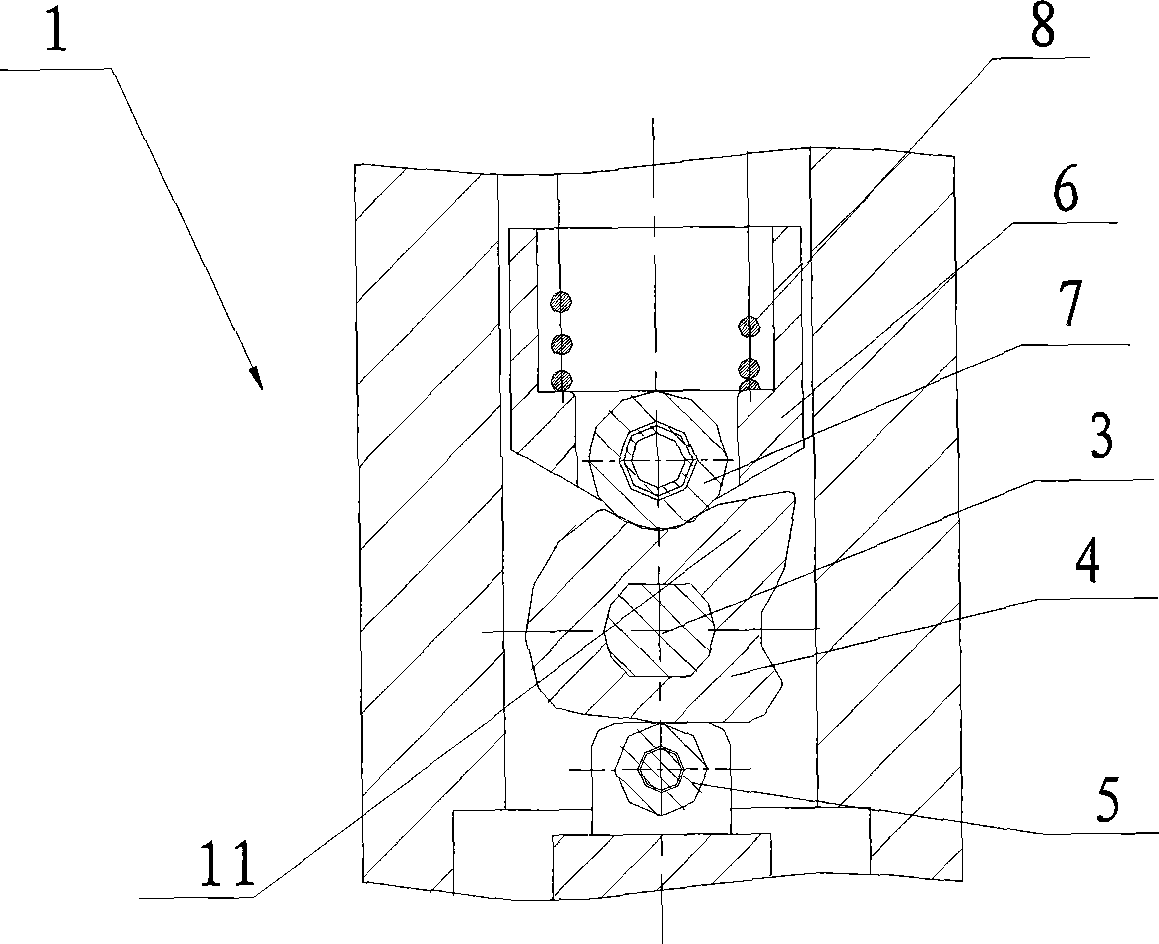

[0015] Such as figure 1 , 2 As shown, a reverse rolling fork-type actuator for travel switches includes a housing 1, a transmission mechanism, and a push rod 2. The transmission mechanism includes a rotating shaft 3 with a rotating arm, and a cam 4 with an irregular cross-section. The cam 4 is sheathed on the head end of the rotating shaft 3, and the two are tightly matched. The head end is located above the push rod 2. The upper end of the push rod 2 is provided with an axial groove, and the pin shaft passes through the groove. A roller 5 is fixed, and the roller 5 is engaged with the cam 4, and the said cam is provided with a protrusion 11 located on its upper right.

[0016] The transmission mechanism also includes a support member 6 that is in close contact with the inner wall of the housing. The support member 6 is located above the head end of the rotating shaft, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap