Electric wire coloring apparatus

A wire and equipment technology, applied in the field of wire coloring equipment, can solve problems such as the inability to identify multiple colored spiral stripes, and achieve the effects of improving visibility and design quality, reducing costs, and reducing inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

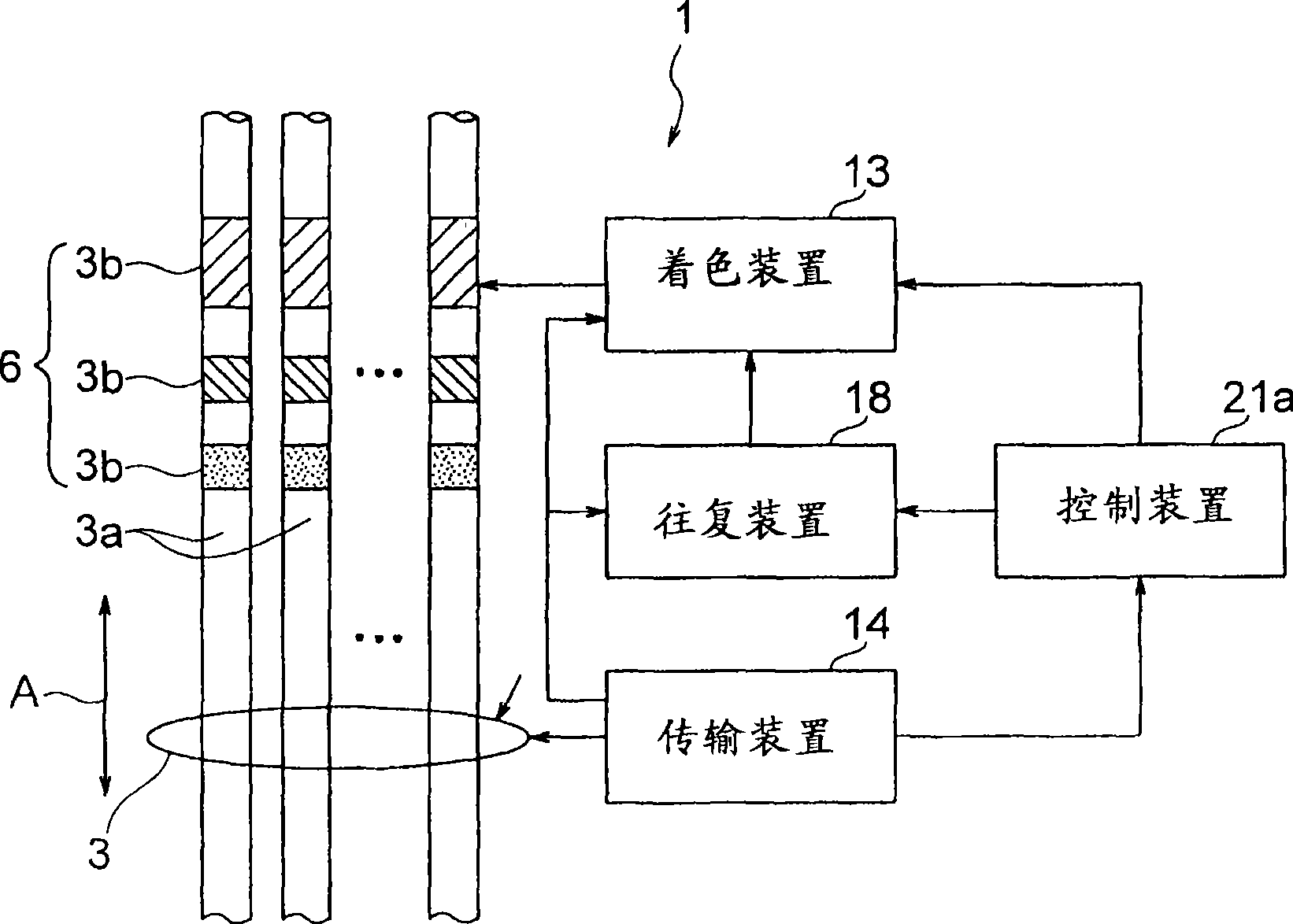

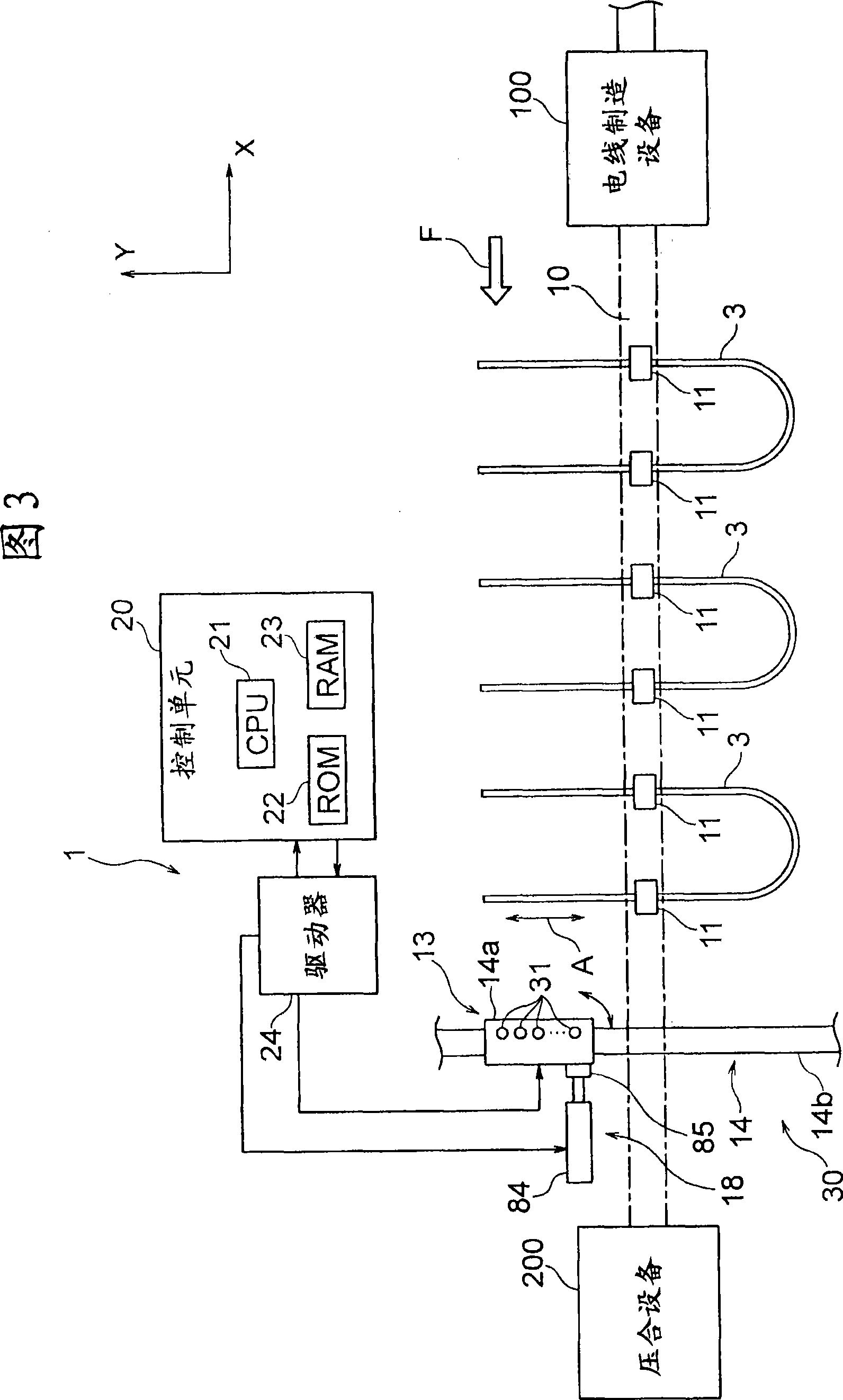

[0051] will refer to Figures 2 to 9 An embodiment of the electric wire coloring apparatus 1 according to the present invention is explained.

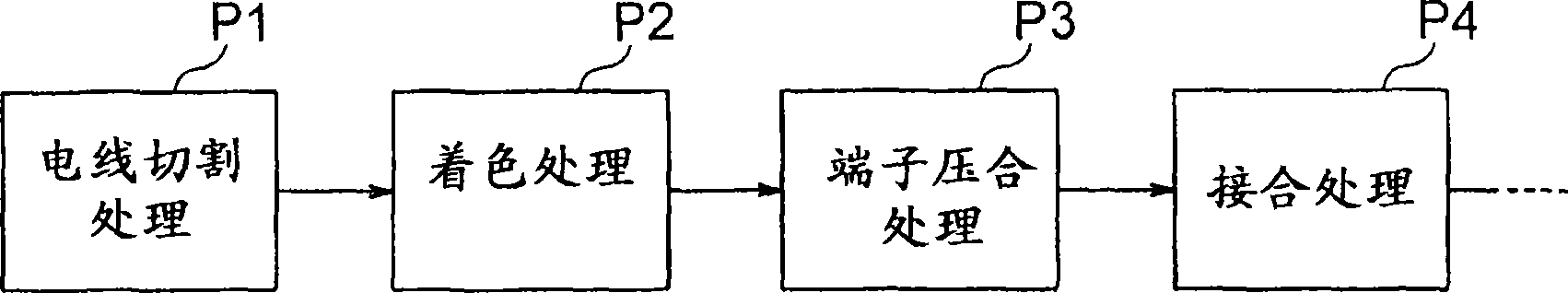

[0052] Such as figure 2 As shown, the wire harness manufacturing system includes wire cutting process P1, coloring process P2, terminal crimping process P3, joining process P4, and the like. In the best mode, the electric wire coloring apparatus 1 is installed on the coloring process P2. If the coloring process P2 is not included in the system, the wire coloring device 1 is installed on the wire cutting process P1, or the terminal crimping process P3.

[0053] In addition, the wire harness includes a plurality of sub-harnesses. Install the sub-harnesses respectively on the corresponding systems in the vehicle. Each sub-harness includes a plurality of wires and connectors attached to ends of the wires.

[0054] The electric wire manufacturing apparatus 100 cuts a long reel-shaped electric wire into electric wires each having a spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com