Connecting member

A technology for connecting components and components, which is applied to the parts, connections, and conductive connections of the connection device, which can solve the problems of time-consuming installation of electrical wiring circuits, unfavorable miniaturization of wire electrical wiring, and inability to branch, etc., to achieve shortening Operation time, simple structure, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

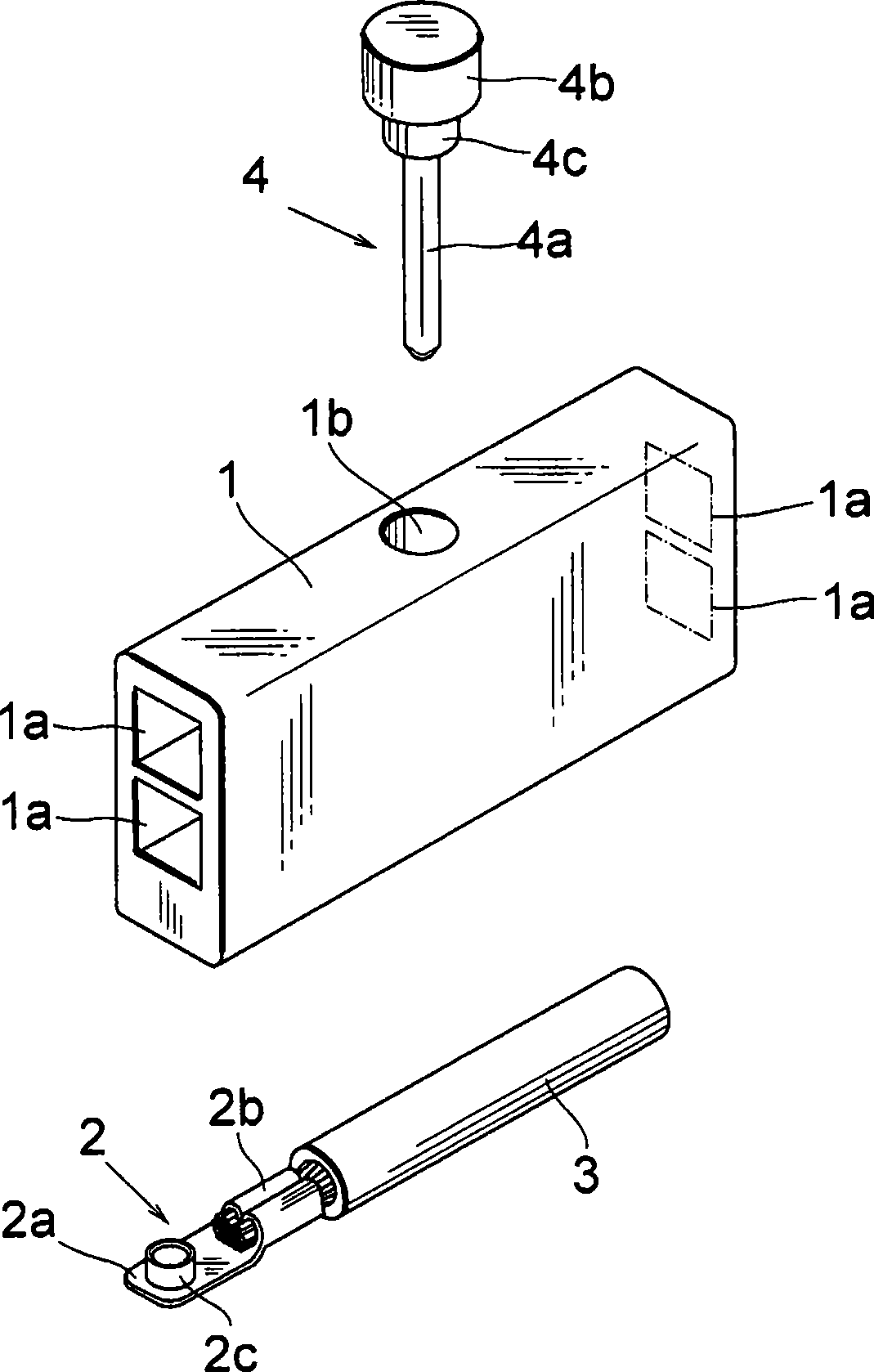

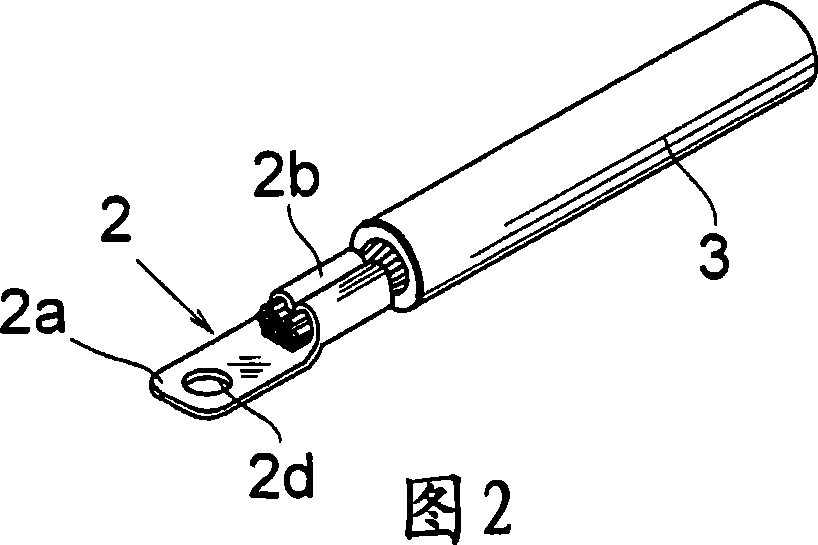

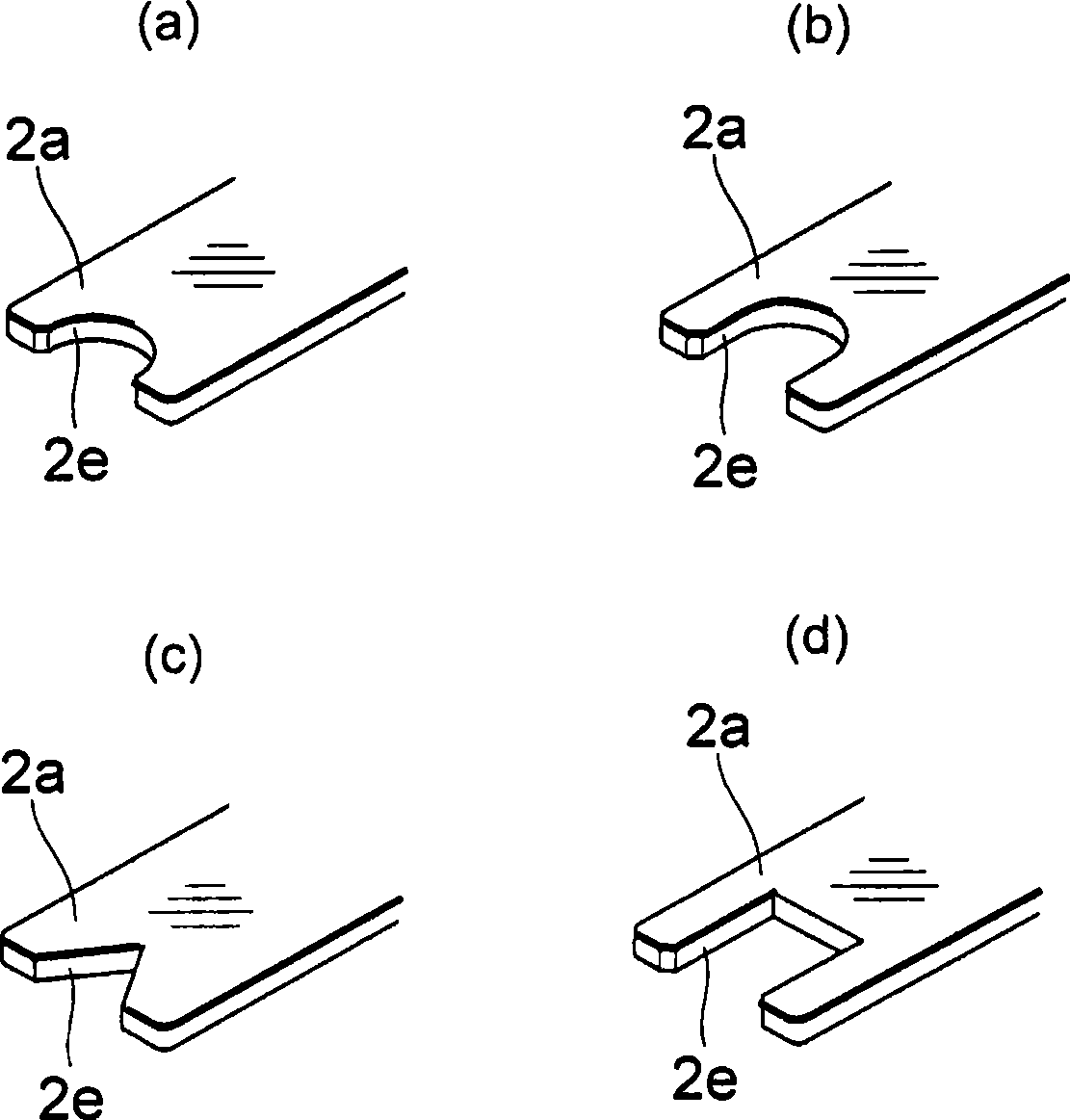

[0030] In Example 1, such as figure 1 As shown in the exploded perspective view of , it is composed of the following components: a holding body 1 made of synthetic resin material having an electric wire terminal insertion hole 1a and a pin terminal insertion hole 1b; A plurality of electric wire terminals 2 of the crimping portion 2b; and a piercing pin 4 composed of a pin terminal 4a, a grip portion 4b, and an intermediate portion 4c.

[0031] A plurality of electric wire terminal insertion holes 1a are formed in the holding body 1 from the left and right sides toward the center, for example, by making the entrance part a square hole, so that the receiving connection end 2a can be inserted to a predetermined position. In addition, the pin terminal insertion hole 1b is formed in the central direction from the upper side of the holder 1, and is formed so as to be perpendicular to the position where the wire terminal insertion hole 1a receives the connection end 2a.

[0032] As...

Embodiment 2

[0053] Figure 7 A perspective view of an assembly of the holder 1, the electric wire terminal 2, and the pin 4 of the waterproof type Example 2 is shown. FIG. 8 shows a perspective view of an assembled state, and FIG. 9 shows a cross-sectional view thereof.

[0054] A cylindrical waterproof seal 5 made of synthetic rubber is inserted into the electric wire 3 on the electric wire terminal 2 side, and is fixed by a seal crimping portion 2 f extending from the electric wire terminal 2 . In addition, the cross section of the entrance of the electric wire terminal insertion hole 1 a of the holding body 1 is circular, and is sealed by a waterproof packing 5 .

[0055] A cylindrical waterproof packing 6 is also inserted in the intermediate portion 4c of the pin 4, and the waterproof packing 6 is attached to the circular entrance of the pin terminal insertion hole 1b.

[0056] In this embodiment 2, waterproof seals 5, 6 can be used to prevent water from infiltrating into the inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com