Filter sleeve with stirring structure

A technology of filter sleeve and filter sleeve, which is applied in the directions of filtration and separation, moving filter element filter, separation method, etc., can solve the problem that the preservation liquid cannot be effectively driven.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Obviously, the solution of the present invention will not be limited only to the embodiment.

[0009] Embodiment is shown in accompanying drawing. For details, please refer to the accompanying drawings.

Description of drawings

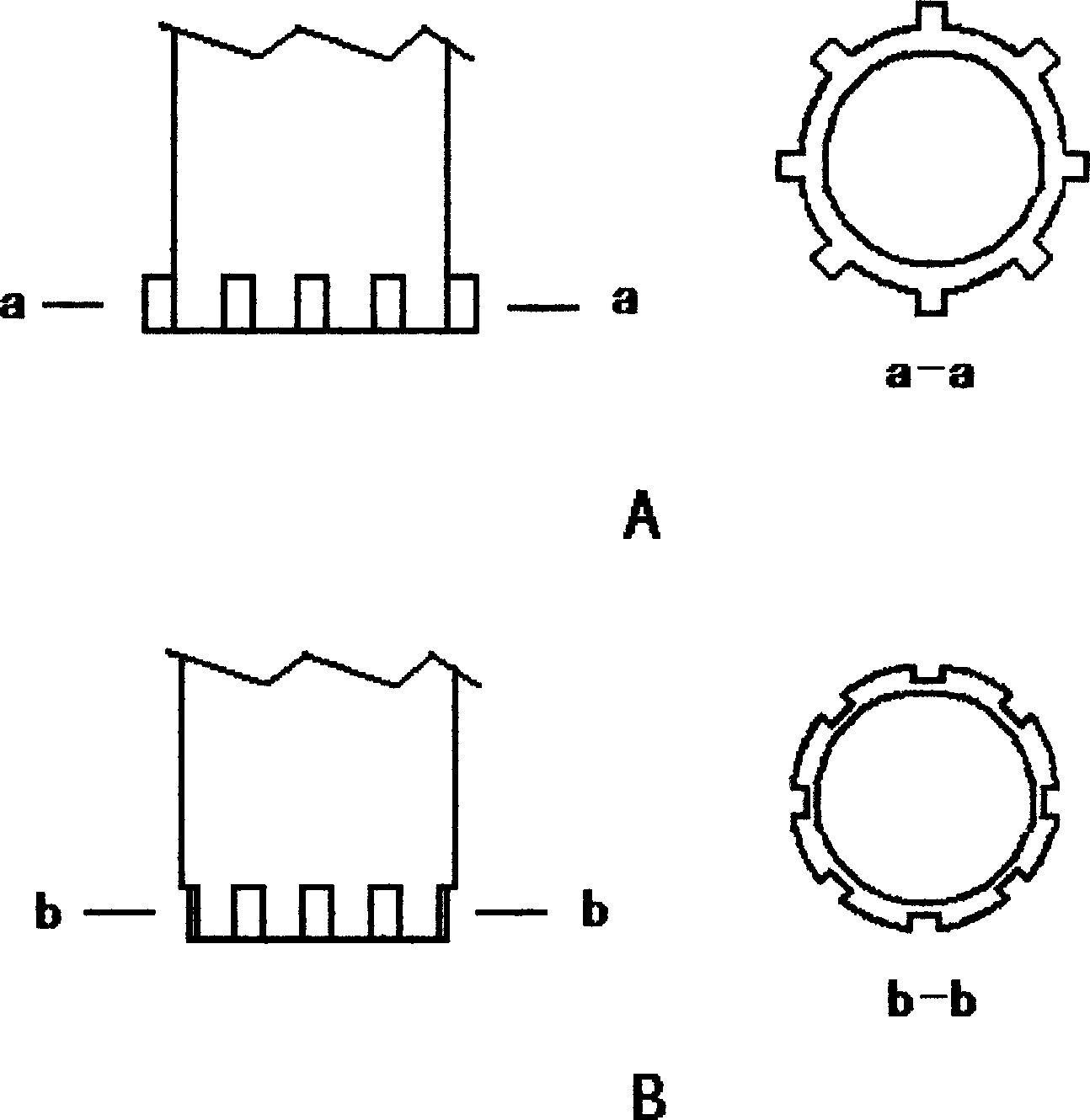

[0010] 1) Accompanying drawing 1 is an embodiment of "adding a raised structure or a groove on the outer wall".

[0011] Scheme A is to add a raised structure on the outer wall, and its cross-section is shown in a-a. The raised structures play a major stirring role. Option B is to add a groove structure on the outer wall, and its cross-section is shown in b-b. Relative to the groove, the outer wall is raised, which plays a major role in stirring.

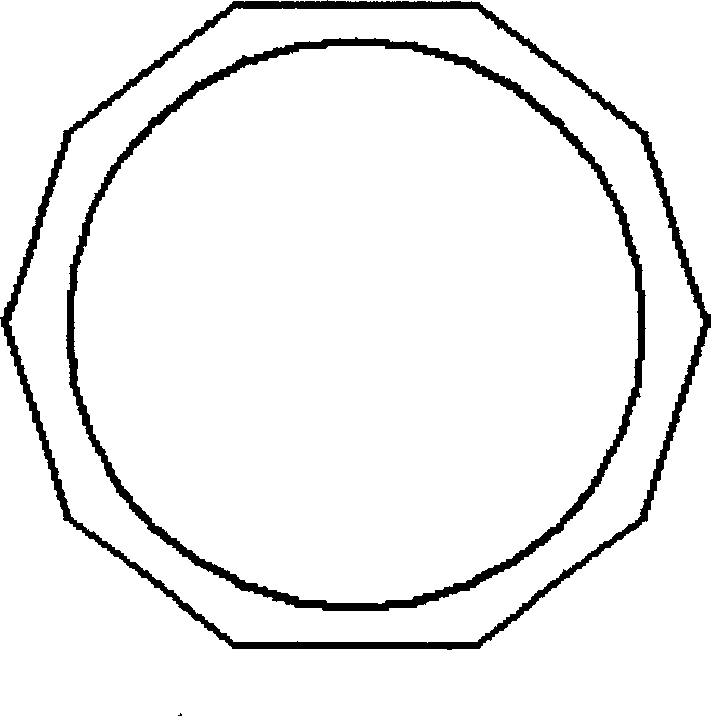

[0012] 2) Accompanying drawing 2 is the embodiment of "changing its cross-sectional shape".

[0013] The outer wall section is polygonal, and the corners and sides of the polygon play a major role in stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com