Mineral dressing and desliming device

A kind of equipment and desliming technology, applied in the direction of solid separation, etc., can solve problems such as difficult maintenance, long maintenance time, and affecting normal production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

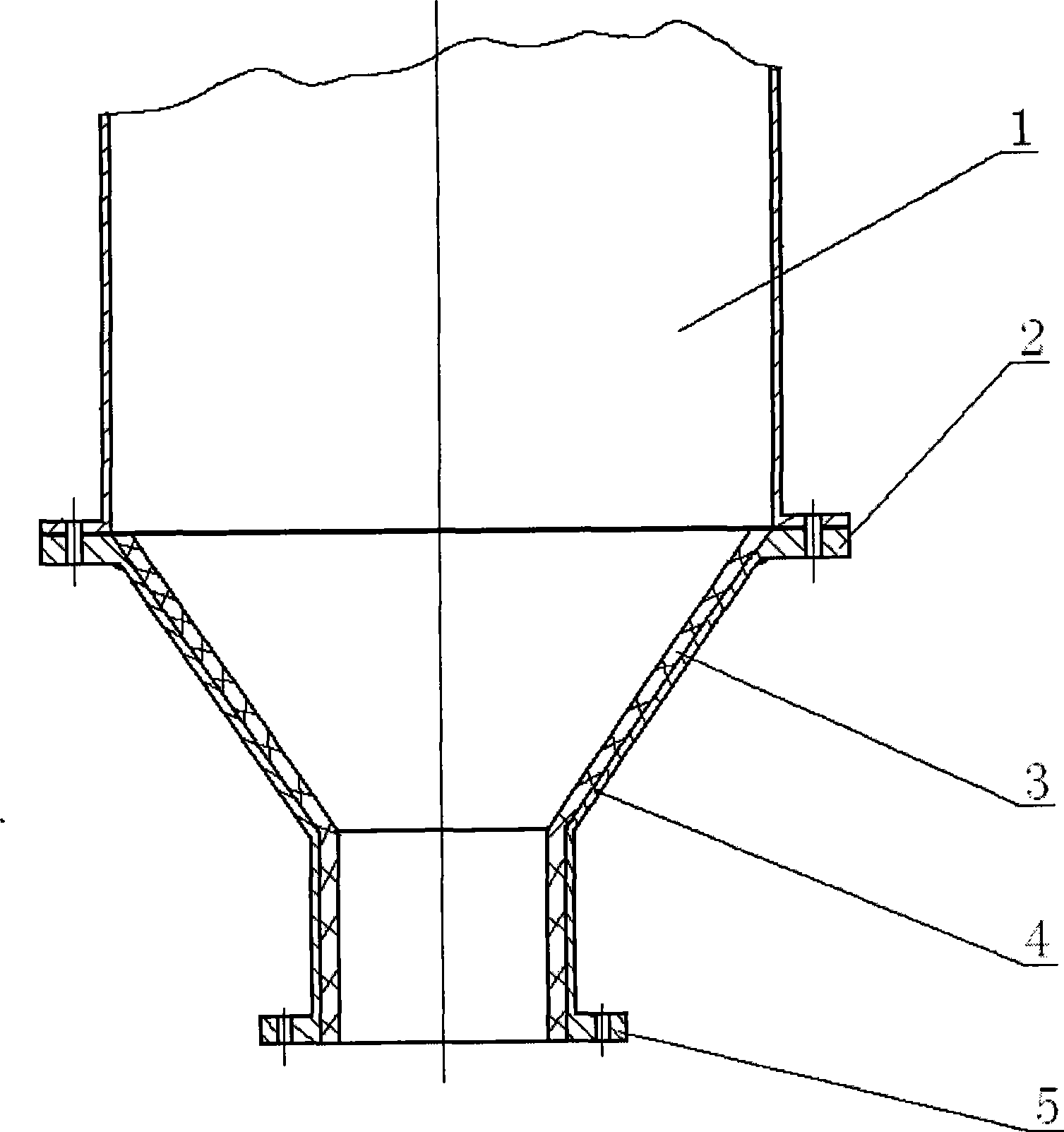

[0011] like figure 1 As shown, the ore dressing and desliming equipment includes a discharge cylinder 1 and a discharge cone. The discharge cone consists of an upper connection flange 2, a discharge cone shell 4, a discharge cone inner lining 3, and a lower connection flange 5. Composition, the discharge cone inner lining 3 and the discharge cone shell 4 fit together, the upper connecting flange 2 is welded on the upper part of the discharge cone shell 4, and the lower connecting flange 5 is welded on the discharge cone shell 4 lower part. The material of discharging cone inner lining 3 is wear-resistant rubber, and thickness adopts 5~12 millimeters.

[0012] The ore dressing and desliming equipment of the present invention adopts such a structure. The unwearable discharge cylinder and the easy to wear discharge cone of the desludge hopper adopt a detachable connection flange structure. When the discharge cone is severely worn after a period of time When maintenance is neede...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com