Wire rope inspection instrument for elevator

A technology for inspection devices and steel wire ropes, applied in textile cables, transportation and packaging, textiles and papermaking, etc., can solve problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

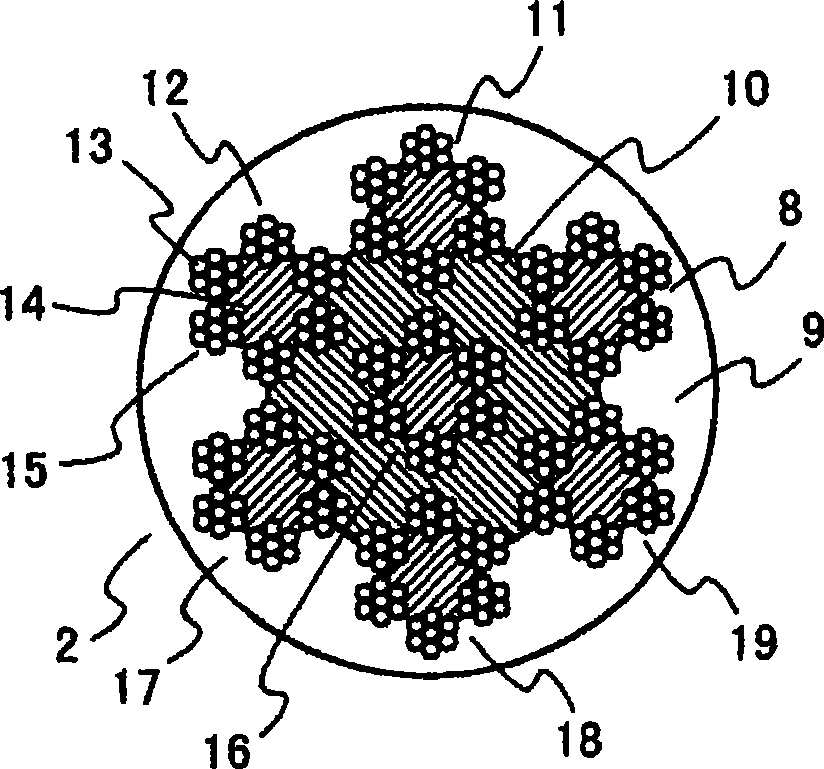

[0032] Steel wire ropes are generally formed by twisting metal wires into twisted wires, and then further twisting the twisted wires. Alternatively the wire rope is formed by twisting the twisted wires into strands and then further twisting the strands.

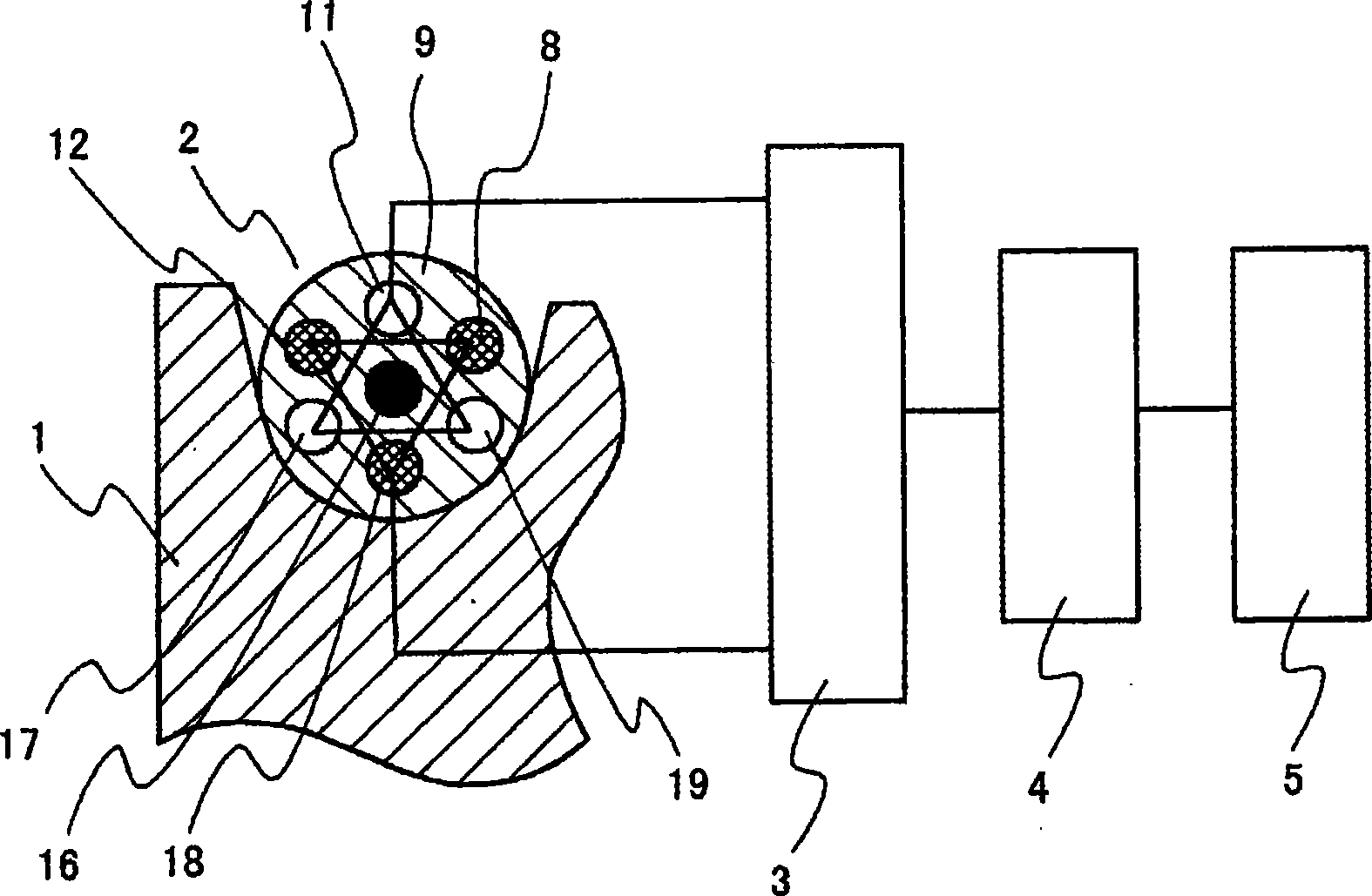

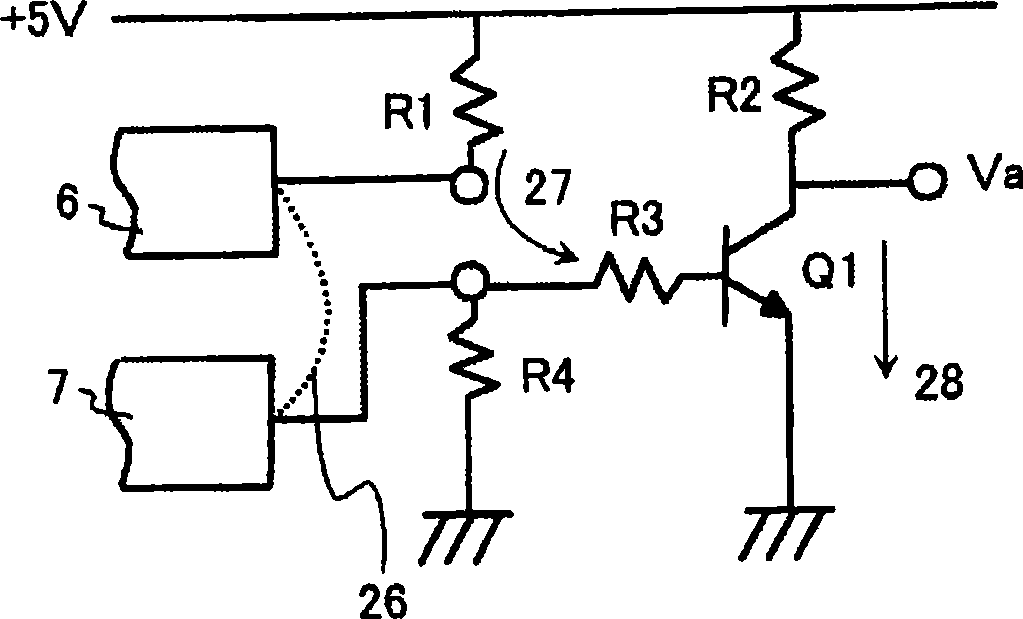

[0033] figure 1 Indicates the structure of the wire rope inspection device. The inspection object of this wire rope inspection device is a steel wire rope 2 which has a plurality of strands 8 , 11 , 12 , 16 , 17 , 18 , 19 and whose outer layer is covered with resin 9 . In addition, this inspection device is installed on the wire rope 2 for a long period of time in order to detect the damage state of the wire rope 2 at a predetermined time period.

[0034] The wire rope 2 passes through the sheave 1 while receiving tension from loads such as the elevator car and counterweights, so it bends every time it passes through the sheave 1 . In the case of long-term use, there will be a slight speed deviation between the resin and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com