Polygon arranged central tube type optical fiber ribbon cable

A central tube-type, ribbon-shaped optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of large signal attenuation and lower performance of optical cables, and achieve the effects of reducing signal attenuation, uniform force, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

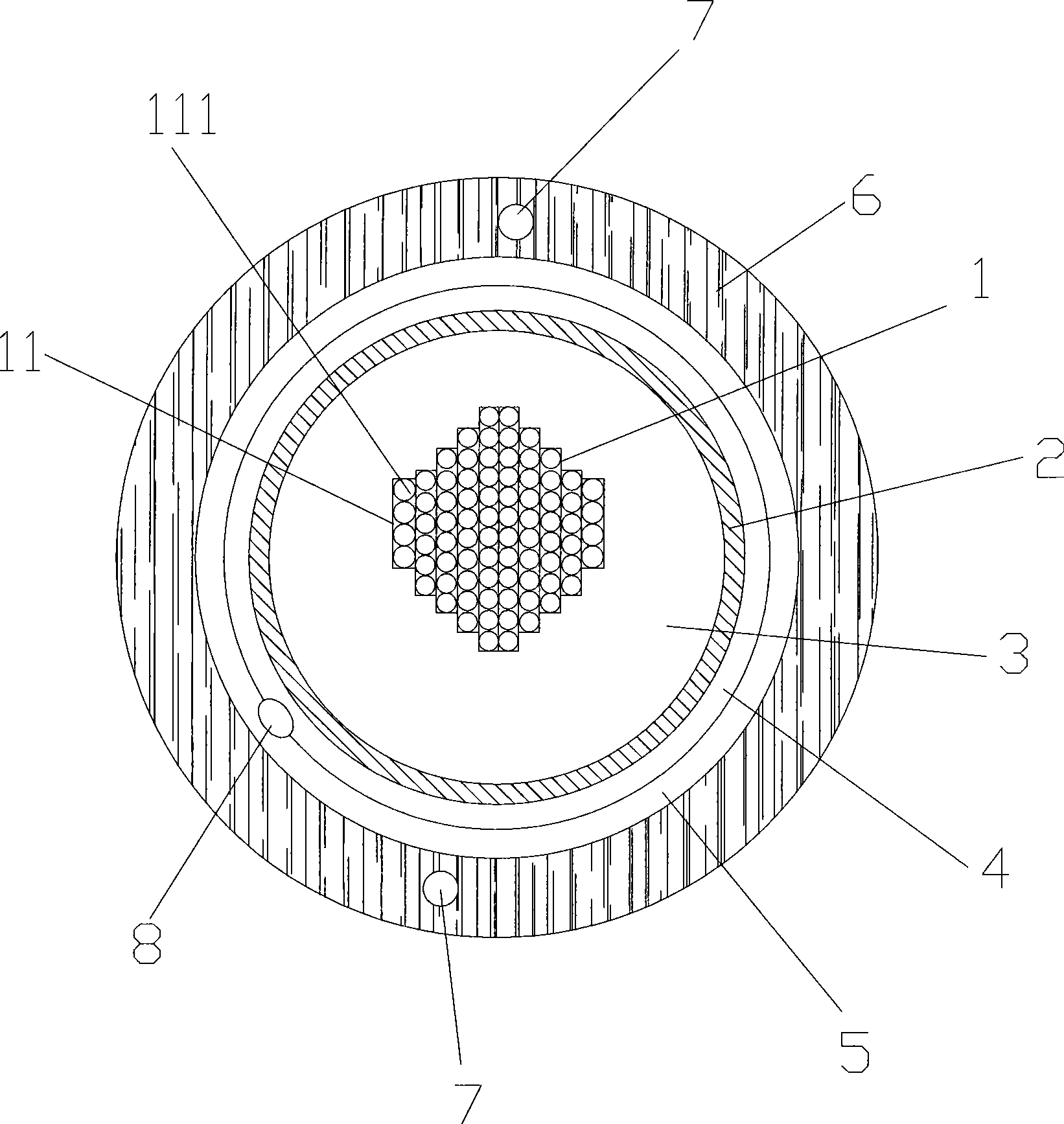

[0012] Embodiment: A central tube-shaped ribbon cable arranged in a polygonal shape, including an optical fiber ribbon group 1 located in the center, a loose tube 2 wrapped outside the optical fiber ribbon group 1, and the space between the loose tube 2 and the optical fiber ribbon group 1 is filled There is fiber paste 3, a tear rope 8 is embedded outside the loose tube 2, the loose tube 2 is covered with a water blocking tape 4, the water blocking tape 4 is covered with a steel-plastic composite tape 5, and the steel-plastic composite tape 5 is outside Covered with an outer sheath 6, embedded in the outer sheath 6 is a reinforcing steel wire 7, the optical fiber ribbon group 1 is formed by stacking several optical fiber ribbons 11, and each optical fiber ribbon 11 is formed by combining several optical fibers 111 side by side;

[0013] The number of optical fibers 111 in each layer of optical fiber ribbon 11 gradually decreases from the inside to the outside, the optical fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com