Processing box

A processing box and handle technology, applied in the field of processing boxes, can solve the problems of increasing the size of the processing box, instability, uneconomical, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The detailed components and elements in the description are provided to provide a comprehensive understanding of the specific embodiments of the invention. Those skilled in the art will then recognize that various changes and modifications of the embodiments described herein can be made without departing from the scope and spirit of the invention. However, descriptions of well-known functions and constructions are omitted for conciseness.

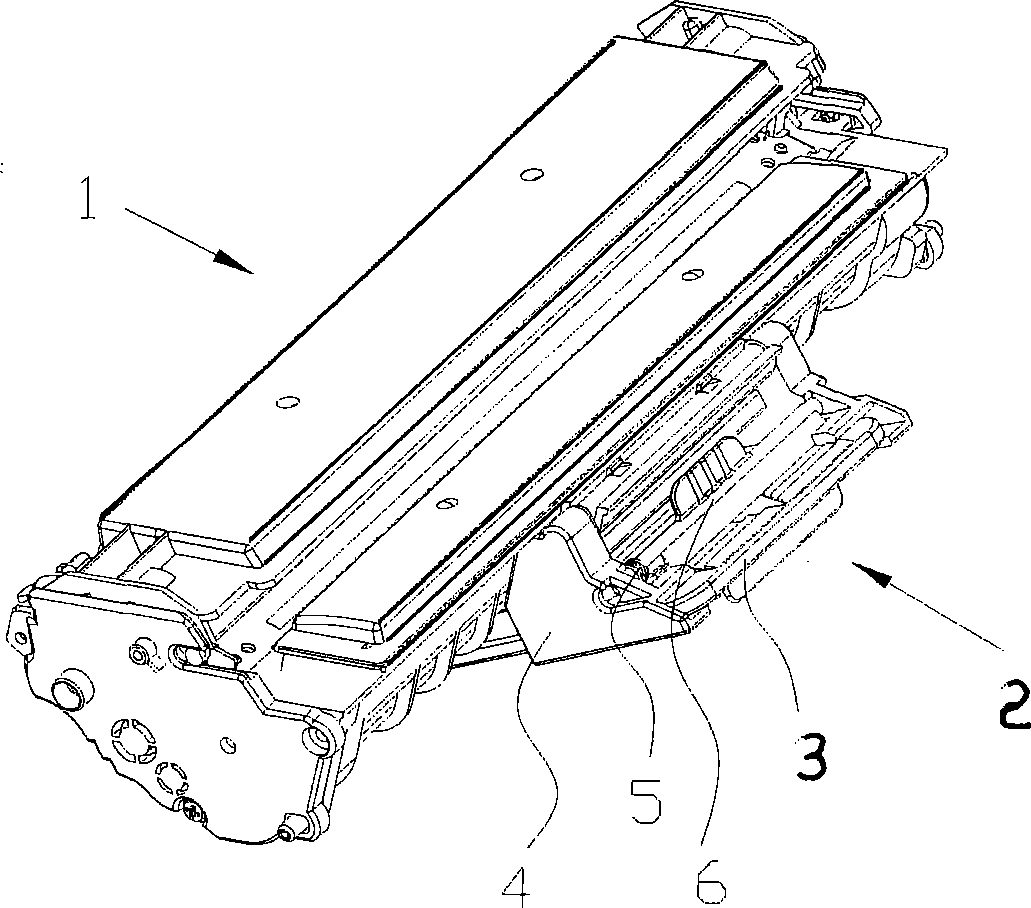

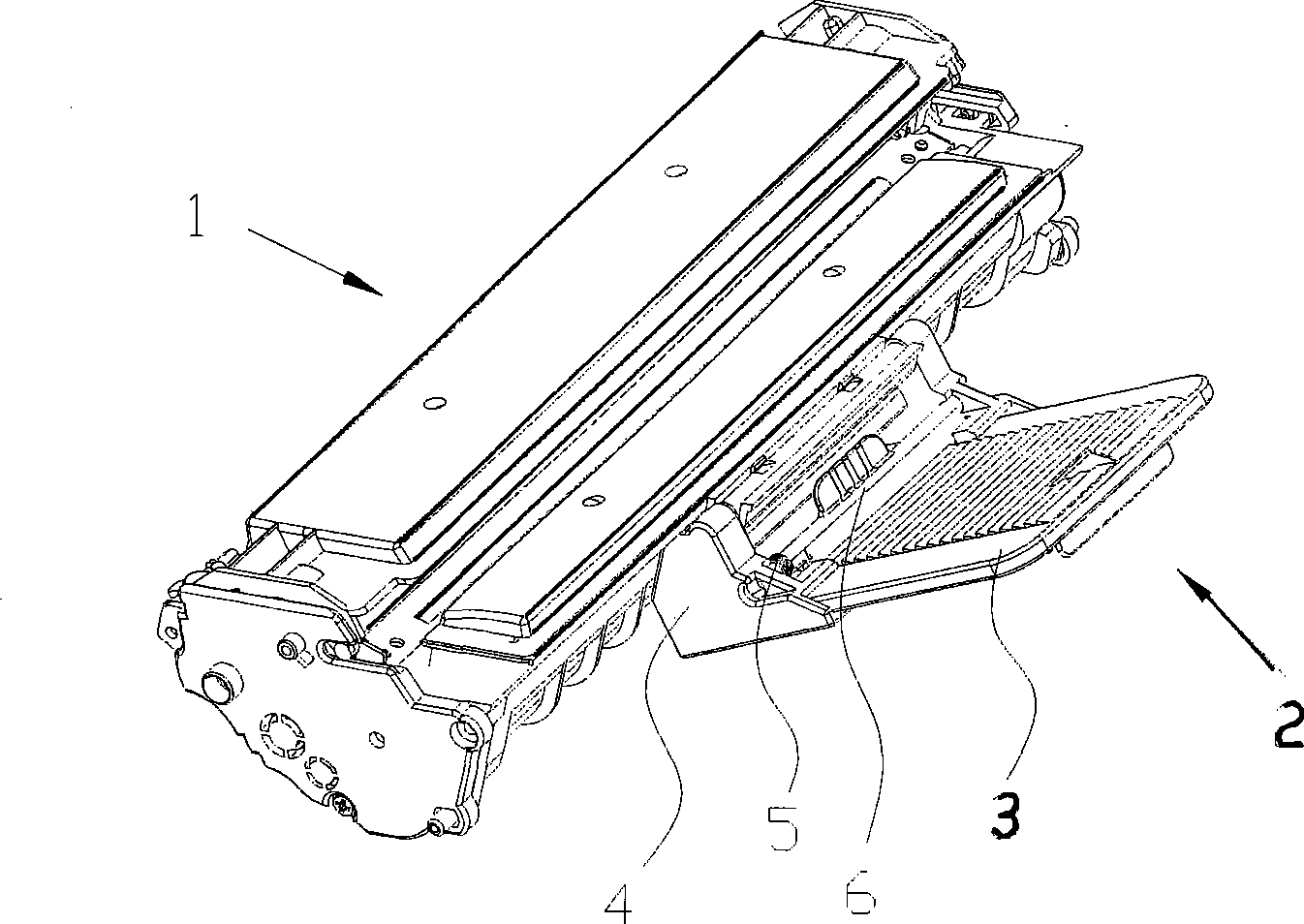

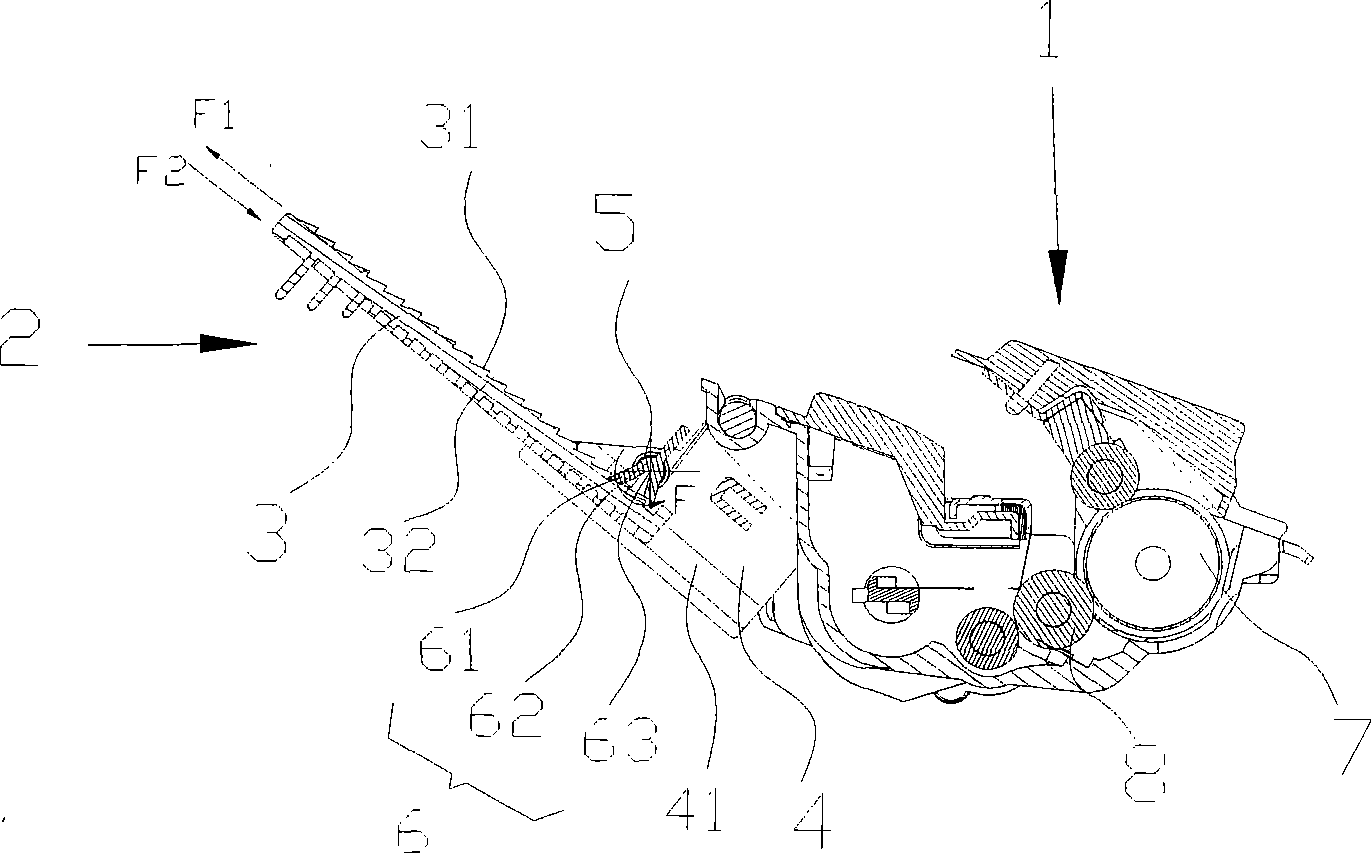

[0022] like figure 1 , 2 , 3, the process cartridge includes a photosensitive drum, a developing roller, a protective case 1 for accommodating the photosensitive drum and the developing roller, and a handle 2. The handle 2 is telescopically installed on the protective shell 1, and is approximately located at the middle position of the protective shell along the axial direction of the photosensitive drum, and has an extended state and a contracted state. The handle 2 includes a handle slider 3 , a handle support 4 , a handle torsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com