Energy conduction chain

A technology of energy guiding and chain links, which is applied in the field of energy guiding chains, can solve problems such as discontinuous movement and lateral displacement of upper branches, and achieve the effect of reducing noise and reliable guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

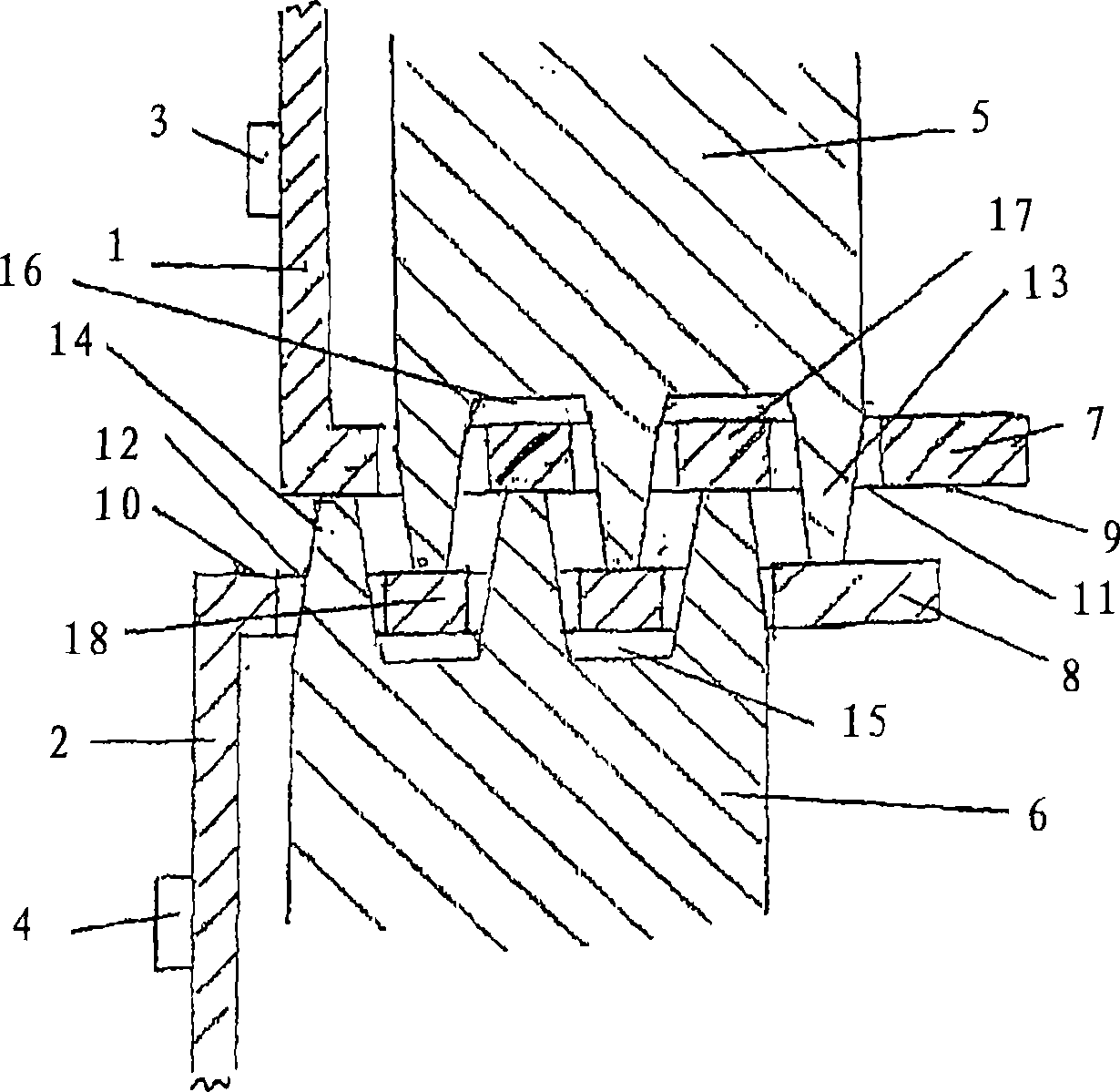

[0022] figure 1 A partial sectional view showing opposite parts of the side straps 1 of the upper branch and the side straps 2 of the lower branch of an energy guiding chain. The pins 3 and 4 are arranged for fastening to the transverse slats not shown in the figure, they are directed towards the inside of the chain link formed by the side straps and the transverse slats, and are placed on their far ends ( shown in the figure) side straps. Rollers 5 , 6 are arranged on the sides of the side webs facing away from the pins 3 , 4 , which are rotatable about a (not shown) horizontal axis in a known manner. These rollers have guide grooves 15 , 16 on their circumference, which are formed on both sides by comb-shaped bodies 13 , 14 . Furthermore, the side webs have extensions 7 , 8 on opposite edges. The opposite surface of the extension serves as the rolling surface 9 , 10 required for the rolling of the rollers 5 , 6 . Longitudinal slots 11 , 12 are provided on these extension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com