Assembling structure of handle and body of glue spraying gun

A grip and gun body technology, which is applied in the field of connection structure between the grip and the gun body of extrusion guns, can solve the problems of poor coordination, the gun body can be disassembled and assembled freely without seeing the gun body, and can not meet the market demand, and achieves obvious technical The effect of improving and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

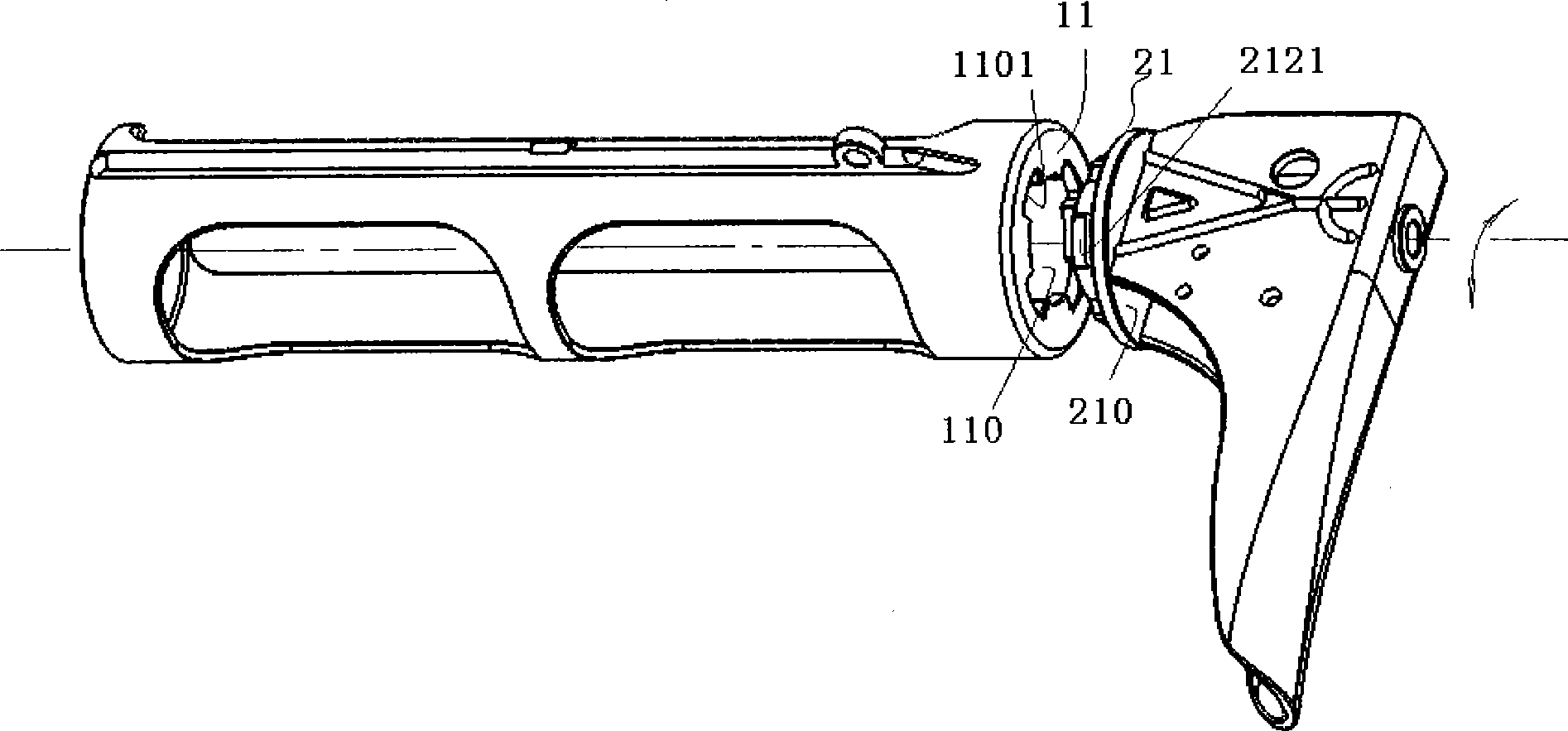

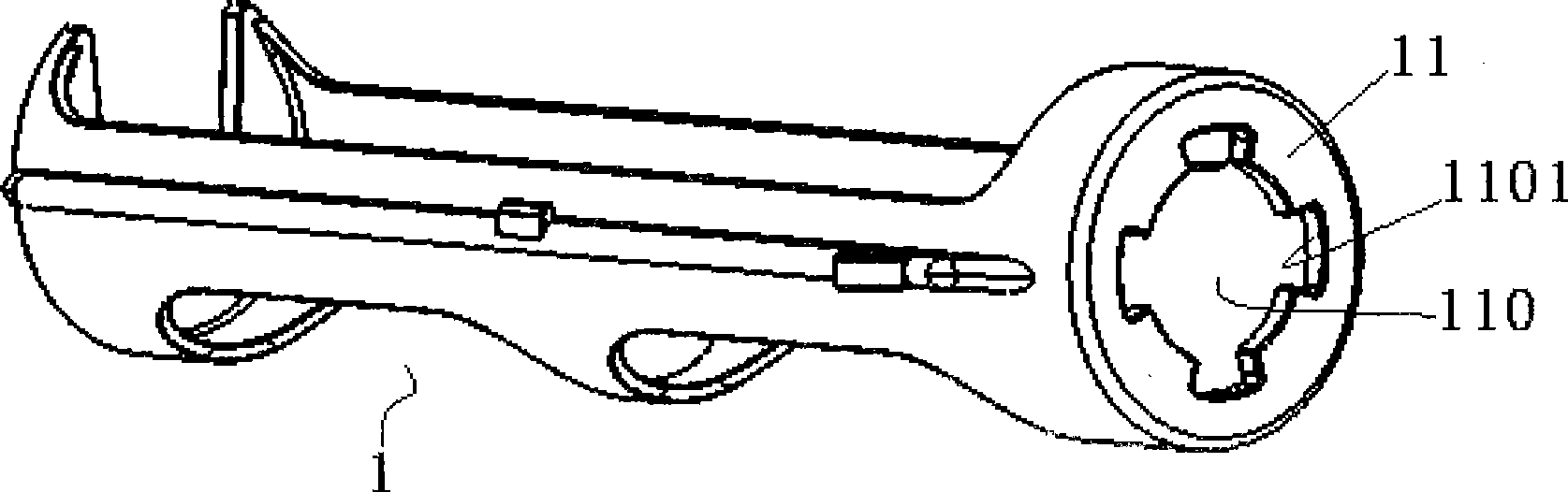

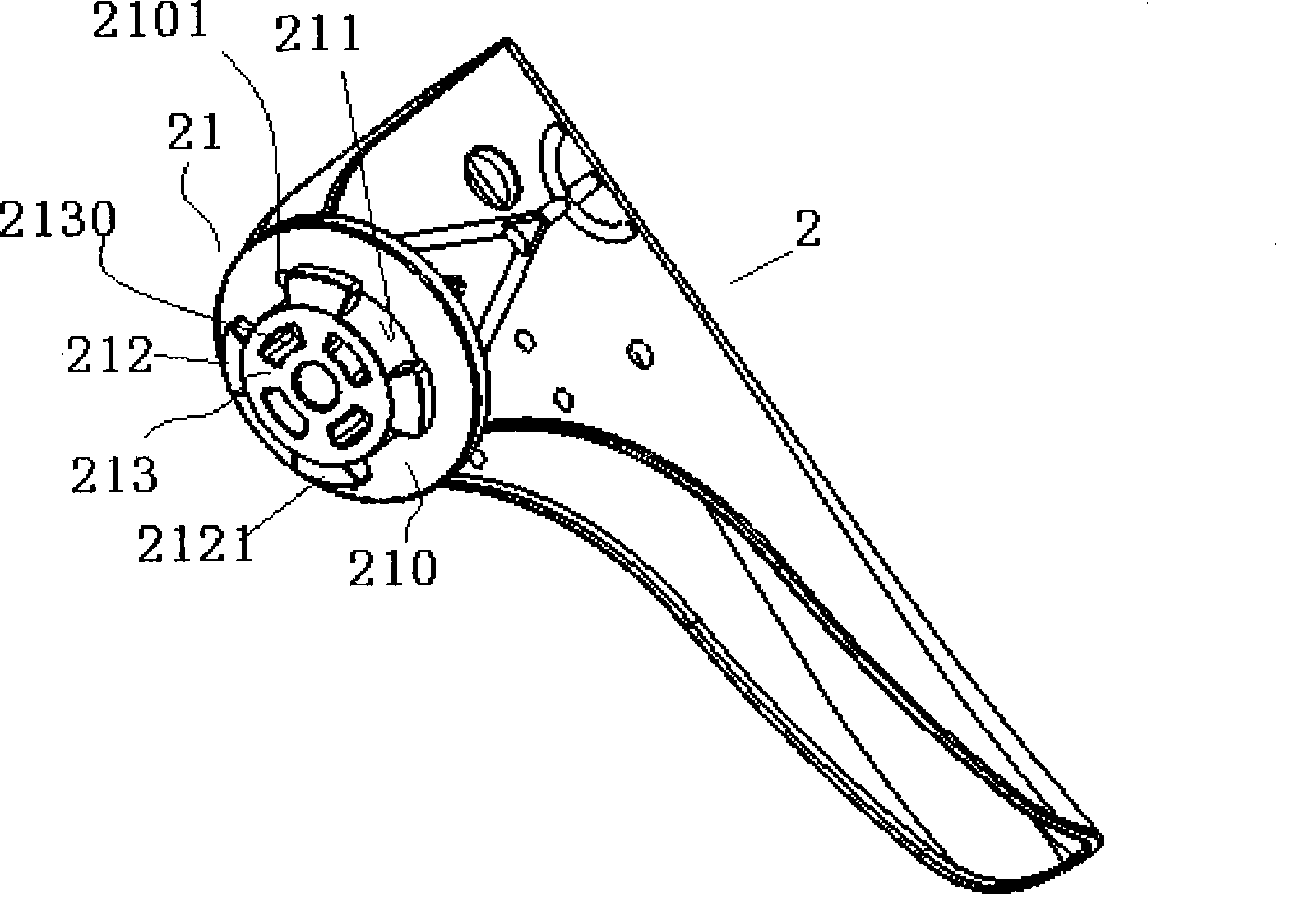

[0025] Such as Figure 1-4 As shown, a kind of assembly structure of the handle and the gun body of a squeeze gun includes a gun body assembly part and a handle assembly part that can be combined with each other, and the push rod 3 is worn through its central hole, wherein the gun body assembly part The handle assembly part is set to a snap-fit structure consisting of a female lock element 11 and a locking element 21; the female lock element 11 can be combined with the gun body 1 (such as image 3 shown), can also be combined with an adapted handle 2 (not shown); the locking element 21 can be combined with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com